Voltage control circuit, method, gate drive circuit and display device

A voltage control circuit and capacitor control technology, which is applied in the field of gate drive circuits, display devices, and voltage control circuits, can solve problems such as poor process compatibility and large reverse cut-off gate-source voltage, and achieve the goal of improving process compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

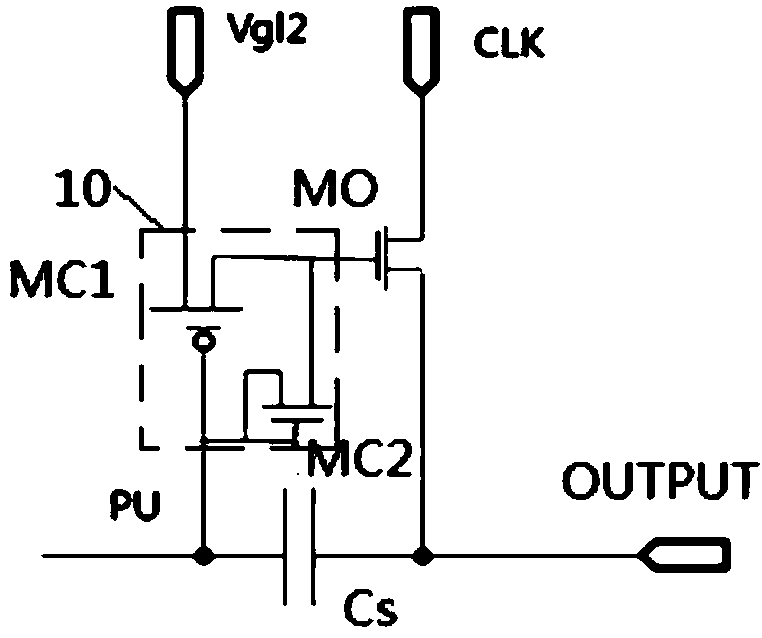

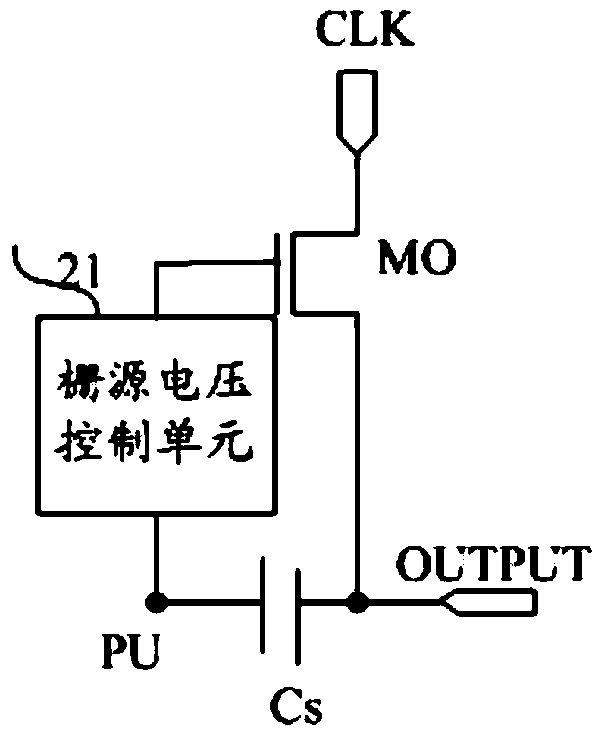

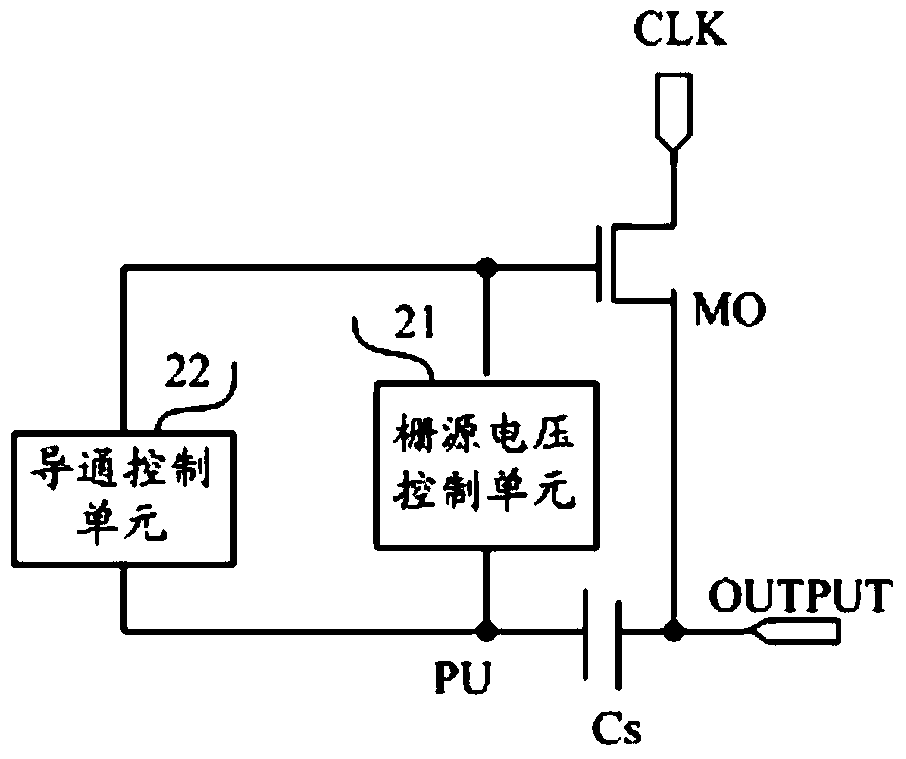

Method used

Image

Examples

no. 2 Embodiment

[0146] Compared with the second specific embodiment, the third specific embodiment of the voltage control circuit of the present invention has been further optimized, and its characteristic is to introduce the first control capacitor C1 and the second control capacitor C2 with equal capacitance values, and adopt CLK and CLKB replace Vdd, reducing a Vdd signal source and adding an implementation method; CLK is responsible for charging C1 and C2; the gate voltage of MF is controlled by C2.

[0147] When the third specific embodiment of the voltage control circuit of the present invention works, as Figure 13 as shown,

[0148] In the preparation period T0 of each display cycle, CLKB is at high level, CLK and CLK' are at low level, MC2 and MC3 are both off, and there is no loop formed between C1 and C2, so C1 and C2 are not charged, and MF is off. open;

[0149] In the output period T1 of each display cycle, CLK and CLK' are high level, CLKB is low level, MC2 and MC3 are both t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com