System for improving denitration operation rate of Siemens 1000MW/600MW ultra-supercritical unit

An ultra-supercritical unit and commissioning rate technology, which is applied in the fields of dispersed particle separation, nitrous oxide capture, gas treatment, etc., can solve the problems of low feed water temperature, low catalyst normal use temperature, and denitrification device out of operation, etc. The system is simple and easy to operate, the structure changes are small, and the investment is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

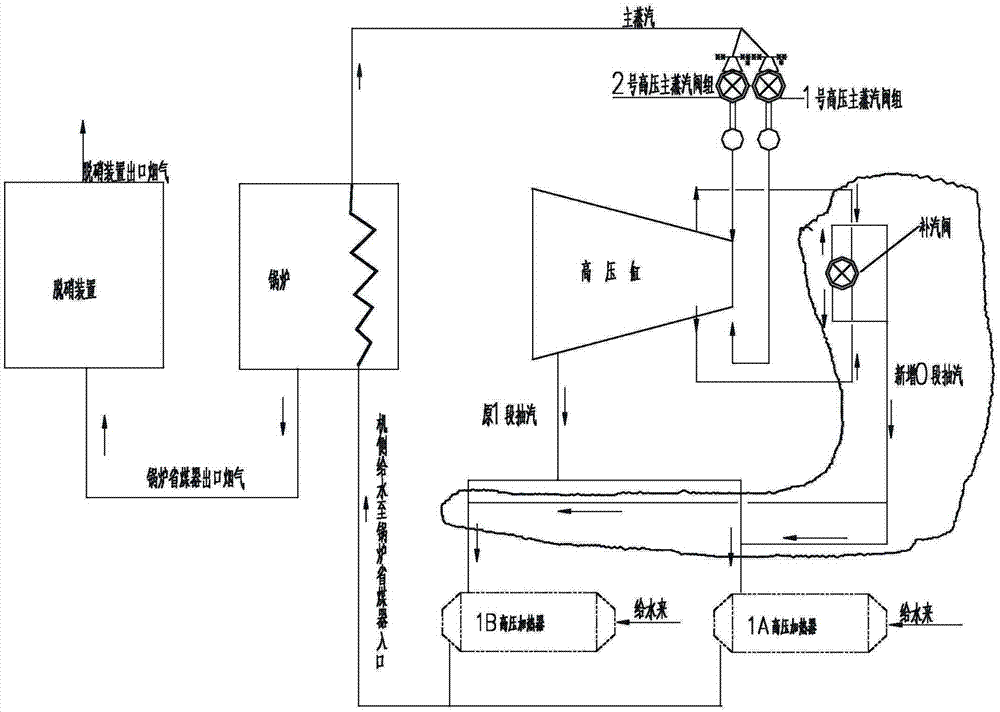

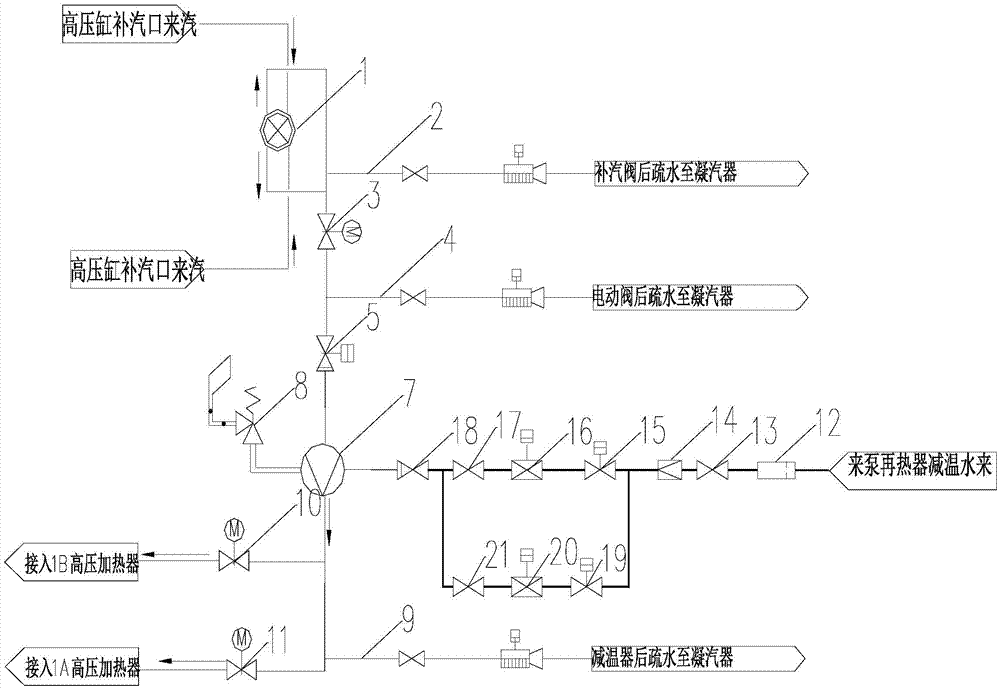

[0023] Such as figure 1 , 2 As shown, a system for improving the denitrification operation rate of Siemens 1000MW / 600MW ultra-supercritical unit includes denitrification device, boiler, high-pressure cylinder and high-pressure heater. Switching from the original 1-stage steam extraction system to the 0-stage steam extraction system, the newly added 0-stage steam extraction process is as follows: reversely extract steam from the inlet of the high pressure cylinder (the steam supplement valve no longer needs to use its original function), in this embodiment, the steam supply valve is used as a steam-operated regulating valve, and after the extracted steam passes through the electric gate valve 3 and the pneumatic check valve 5, it enters the steam desuperheater 7 (with a safety valve 8 to prevent system overpressure) for desuperheating , decompression to meet the safety requirements of the high-pressure heater and the temperature rise of the feed water. After the temperature re...

Embodiment 2

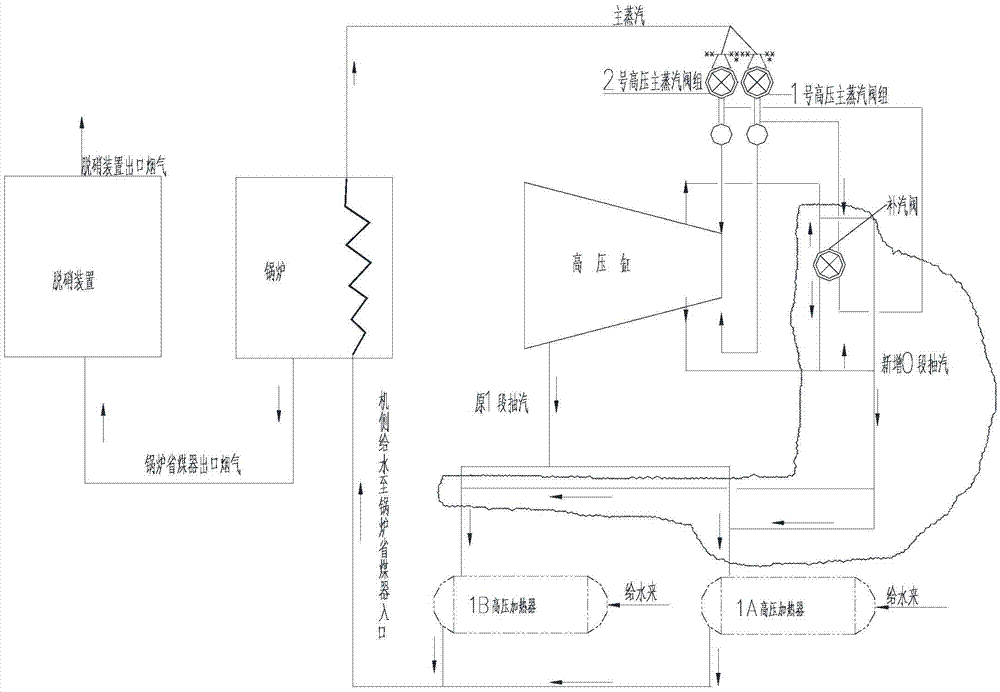

[0026] Reference attached image 3 , 4 , the newly added 0-stage steam extraction process is: reversely extract steam from the steam supply inlet of the high-pressure cylinder (at this time, the steam supply valve is closed to isolate the main steam), and the steam extraction passes through the electric gate valve 3 and the pneumatic check valve 5 Finally, enter the pneumatic control valve 6 and steam desuperheater 7 (with safety valve 8 to prevent system overpressure) for temperature reduction and decompression to meet the safety requirements of the high-pressure heater and feed water temperature rise. After desuperheating and decompression, the steam It is divided into two branches, A and B, which are respectively connected to 1A high-pressure heater and 1B high-pressure heater through electric gate valve 10 and electric gate valve 11. The system sets up necessary drainage pipelines according to the pipeline layout and operation requirements, as shown in Figure 2 and 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com