Desulfurizer packing structure for desulfurization reactor and packing method thereof

A technology of desulfurization agent and reactor, which is applied in the field of desulfurization agent filling structure and its filling, can solve the problems that the device cannot run continuously and stably for a long period, the operation period of the desulfurization reactor is short, and the desulfurization agent cannot be fully utilized, etc., to achieve The effect is obvious, the effect of prolonging the operation period and prolonging the service period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

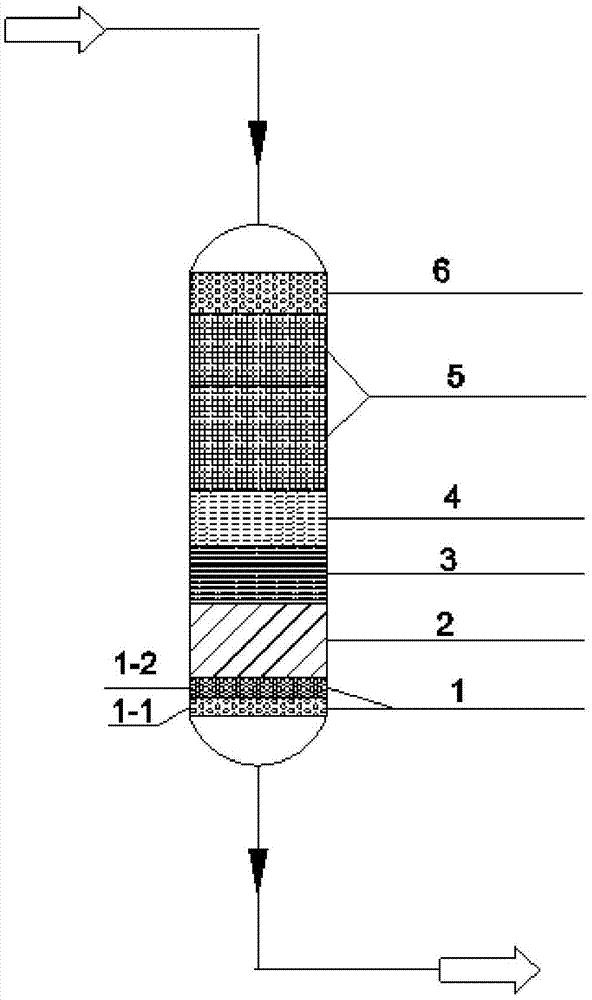

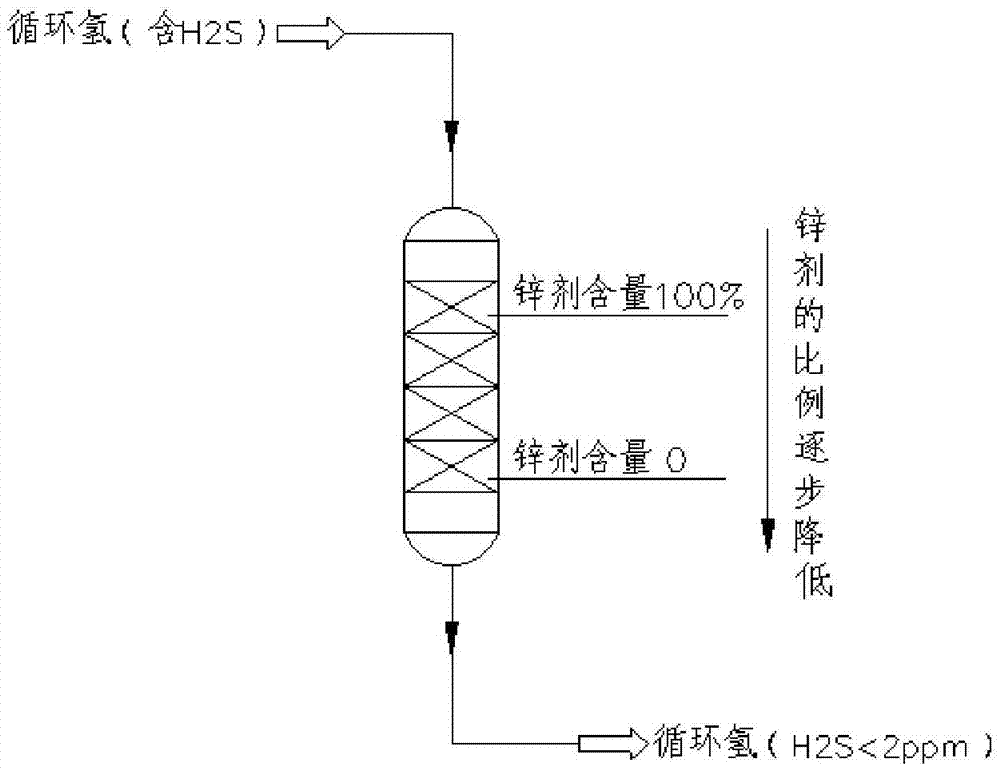

[0038] image 3 The new desulfurizer type and mixed filling scheme adopted this time are shown in . The bottom of the desulfurization reactor is filled with Φ13 inert ceramic balls, the actual loading mass is 740kg, and the filling height is 150mm, forming the bottom layer of inert ceramic balls a1-1. The upper part of Φ13 inert ceramic balls is filled with 900kg of Φ6 inert ceramic balls, and the filling height is 160mm to form the bottom layer of inert ceramic balls b1-2. In the upper part of the bottom layer 1 of the inert ceramic ball, the desulfurizer is filled in four proportions, firstly, the iron oxide desulfurizer is filled separately, the filling height is 1000mm, the filling weight is 4320kg, and the filling density is 1.1364 tons / m 3 , forming the iron oxide desulfurizer layer 2. The upper part is zinc oxide: iron oxide is filled at a ratio of 5:5, the filling height is 930mm, the filling quality is 4125kg, and the filling density is 1.1668 tons / m 3 , forming th...

Embodiment 2

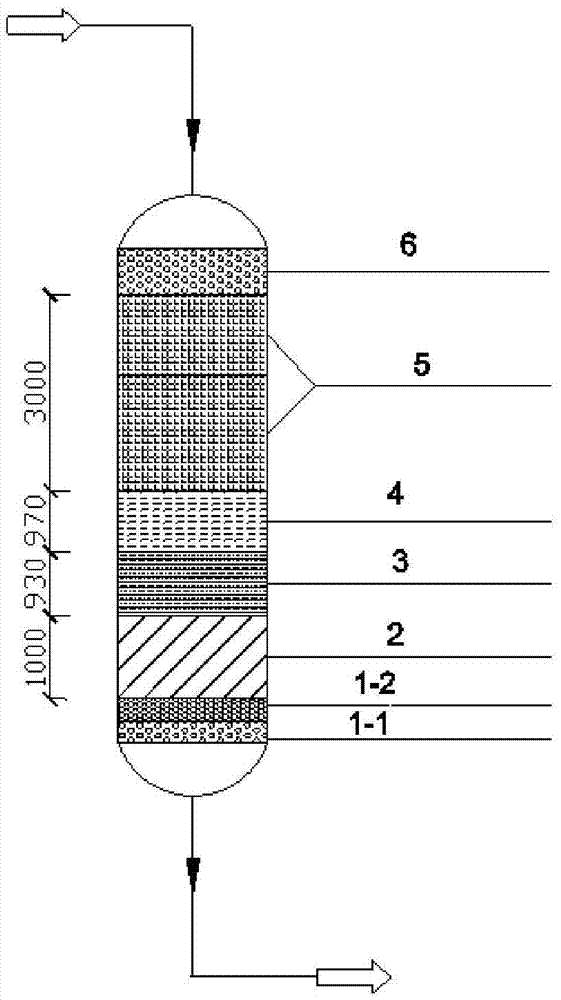

[0041] Figure 4 shows another desulfurizer mixed loading scheme. The difference between this desulfurizer mixed filling scheme and the previous scheme is that when zinc oxide: iron oxide is loaded at a ratio of 5:5, the filling height is changed to 1000mm, the filling mass is 4435kg, and the filling density is 1.1668 tons / m 3 . When the upper layer is zinc oxide: iron oxide is 7:3, the filling height is changed to 900mm, the filling quality is 3925kg, and the filling density is 1.1472 tons / m 3 . Then the upper layer is changed to one-time zinc oxide filling alone, the filling height is 2700mm, and the filling quality is 12385kg respectively. The packing density is 1.1598 tons / m 3 . After the desulfurizer is filled, fill with Φ13 inert ceramic balls, the filling mass is 1960kg, the filling height is 420mm, and the filling density is 1.2272 tons / m 3 .

[0042] The overall desulfurization agent of this kind of filling scheme is relatively reduced, which is economical and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com