Deep desulfurization method for shaft furnace flue gas

A deep desulfurization and flue gas technology, applied in separation methods, chemical instruments and methods, climate sustainability, etc., can solve the problems of low desulfurization efficiency, unsatisfactory desulfurization effect, air pollution, etc., and improve desulfurization efficiency and desulfurization effect. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

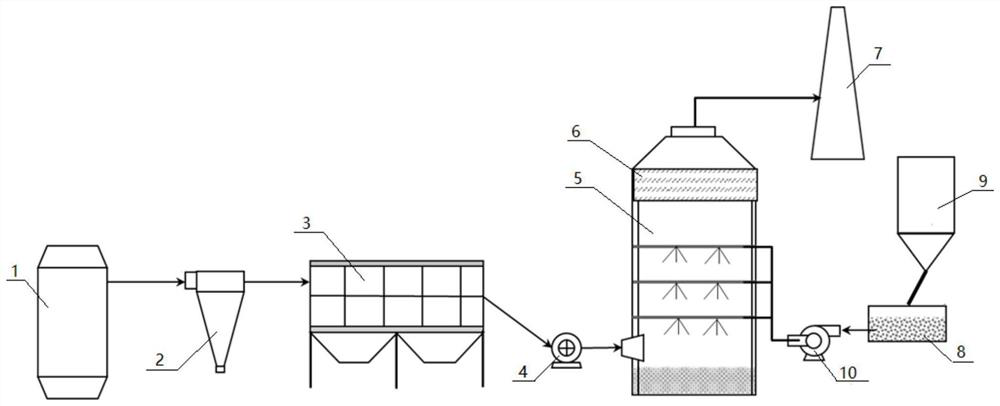

[0019] like figure 1 As shown, a deep desulfurization method for shaft furnace flue gas includes the following steps:

[0020] a. Desulfurization slurry preparation: add desulfurization additive powder into the desulfurization slurry storage tank 8 filled with water and stir evenly to obtain a mixture, the addition amount of the desulfurization additive is 3wt% of the mixture; the desulfurization additive is prepared by the following components by weight 50 parts of sodium carbonate, 35 parts of magnesite, 10 parts of magnesium sulfate, 5 parts of oxalic acid, the content of magnesium carbonate in the magnesite is at least 98wt%, then grind the limestone into powder and add it through the lime silo 9 to mix Among the materials, the desulfurization slurry is obtained after full stirring, and the content of calcium carbonate in the limestone is greater than 90wt%, and the content of limestone in the desulfurization slurry is 25wt%;

[0021] b. The sulfur-containing flue gas gen...

Embodiment 2

[0025] like figure 1 As shown, a deep desulfurization method for shaft furnace flue gas includes the following steps:

[0026] a. Desulfurization slurry preparation: add desulfurization additive powder into the desulfurization slurry storage tank 8 filled with water and stir evenly to obtain a mixture, the addition amount of the desulfurization additive is 4wt% of the mixture; the desulfurization additive is prepared by the following components by weight 50 parts of sodium carbonate, 35 parts of magnesite, 10 parts of magnesium sulfate, 5 parts of oxalic acid, the content of magnesium carbonate in the magnesite is at least 98wt%, then grind the limestone into powder and add it through the lime silo 9 to mix Among the materials, the desulfurization slurry is obtained after full stirring, and the content of calcium carbonate in the limestone is greater than 90wt%, and the content of limestone in the desulfurization slurry is 28wt%;

[0027] b. The sulfur-containing flue gas gen...

Embodiment 3

[0031] like figure 1 As shown, a deep desulfurization method for shaft furnace flue gas includes the following steps:

[0032] a. Desulfurization slurry preparation: add desulfurization additive powder into the desulfurization slurry storage tank 8 filled with water and stir to obtain a mixture, and the addition amount of the desulfurization additive is 5wt% of the mixture; the desulfurization additive is prepared by the following components by weight 50 parts of sodium carbonate, 35 parts of magnesite, 10 parts of magnesium sulfate, 5 parts of oxalic acid, the content of magnesium carbonate in the magnesite is at least 98wt%, then grind the limestone into powder and add it through the lime silo 9 to mix Among the materials, the desulfurization slurry is obtained by fully stirring, and the content of calcium carbonate in the limestone is greater than 90wt%, and the content of limestone in the desulfurization slurry is 30wt%;

[0033] b. The sulfur-containing flue gas generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com