Self-adjusting pipe counterweight coating trolley

A self-adjusting and pipeline technology, applied in the field of engineering applications, can solve the problems of restricting the production efficiency and popularization and application of marine counterweight pipes, and achieve the effects of stable scissor mechanical structure, improved quality and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

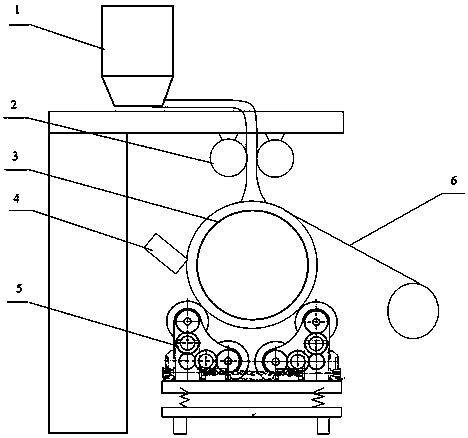

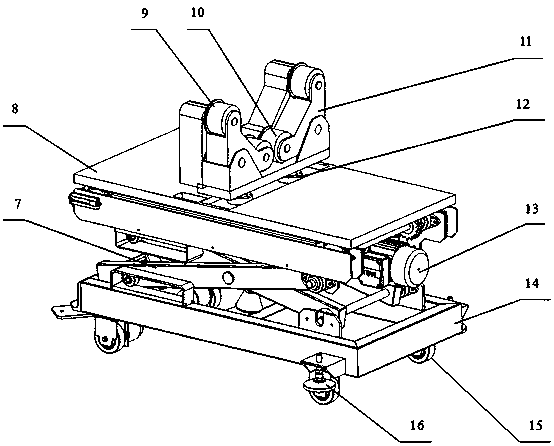

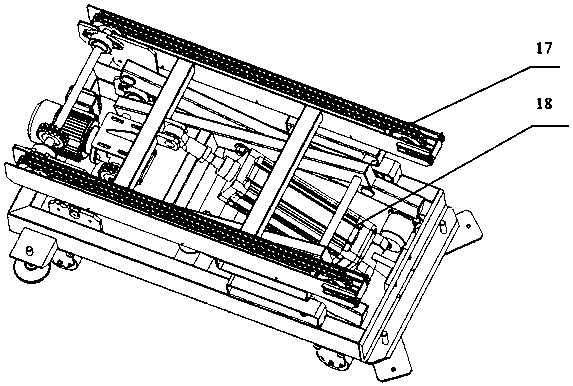

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0021] The self-adjusting pipeline counterweight coating trolley of the present invention is mainly composed of a rotary motion system, a scissor lift platform, a real-time weighing system and a control system. The rotary motion system is mainly composed of a drive motor 13, a sprocket drive 17, a gear drive 5, a support base 11, a main support wheel 9 and a secondary support wheel 10. The same coating trolley is provided with main and auxiliary support wheels (9, 10) with different spacing sizes, the main support wheels 9 with large spacing support large-diameter pipes, and the auxiliary support wheels 10 with small spacing support small-diameter pipelines; the main and auxiliary support wheels ( 9, 10) are covered with a rubber layer to increase friction to prevent slipping, and one end of the main a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com