Large-scale injection machine template gliding foot mechanism

A technology for injection molding machines and templates, which is applied in the field of large injection molding machines, can solve problems such as the inability to guarantee the parallelism between the template and the horizontal plane template, the complex structure of the sliding foot mechanism, and the difficult control of the adjustment amount, so as to ensure the parallelism, improve the bearing capacity, and extend the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

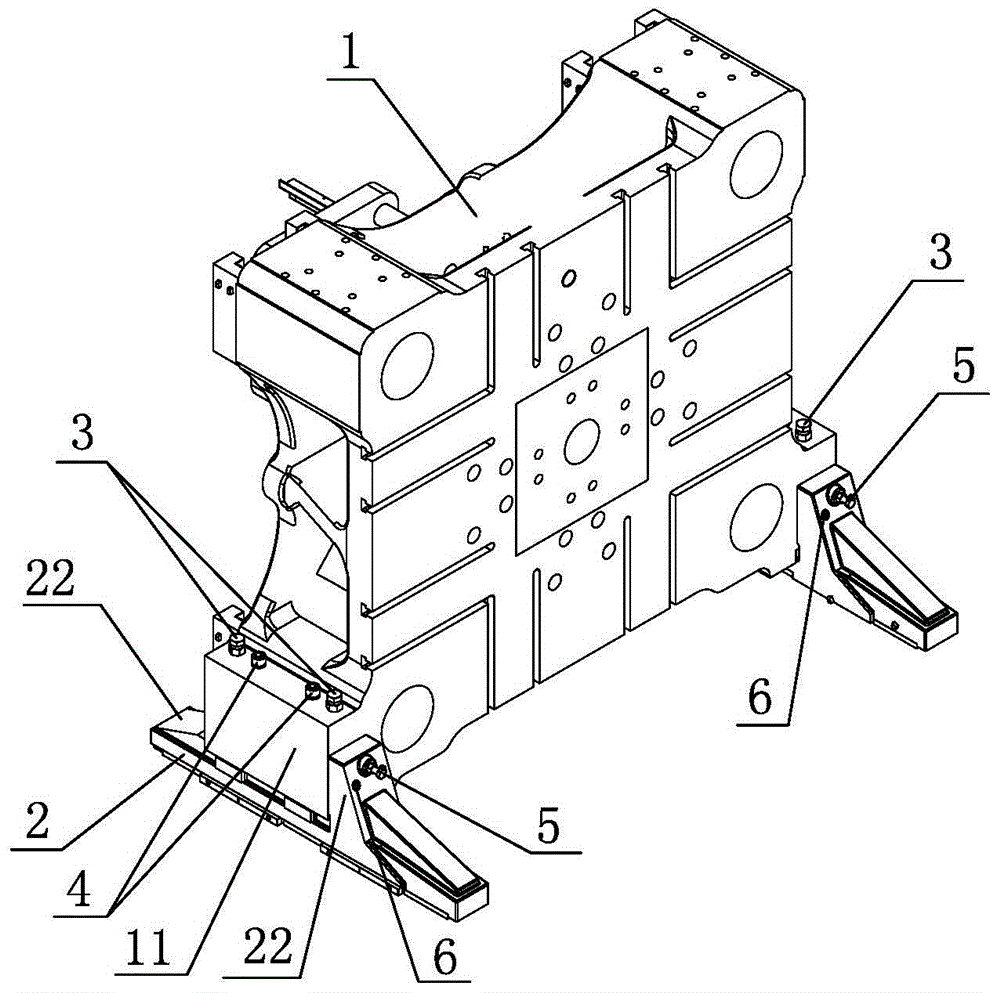

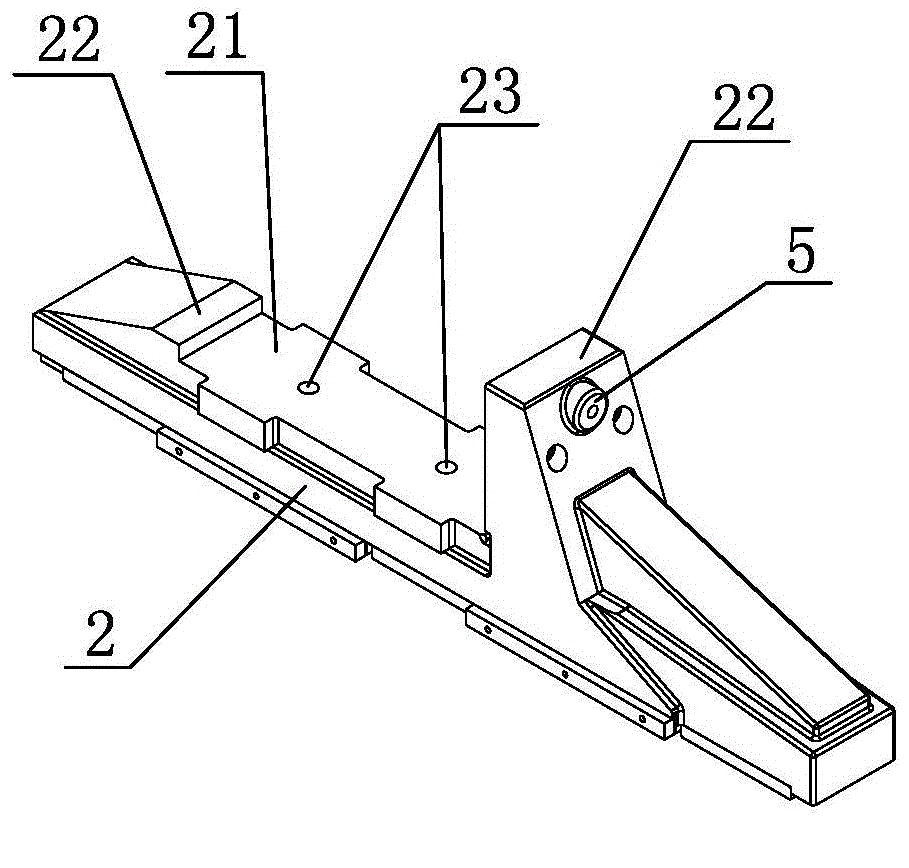

[0010] As shown in the figure, a sliding foot mechanism for a template of a large injection molding machine includes support feet 11 integrally arranged on the front and rear sides of the lower end of the template 1, and the frame of the injection molding machine (not shown in the figure) is provided with position and support The foot 11 corresponds to the foot base 2, the upper plane of the foot base 2 is a horizontal support surface 21, the left and right sides of the foot base 2 are integrally provided with vertical stops 22, the support foot 11 is placed on the horizontal support surface 21 and Located between the left and right vertical blocks 22, two sets of vertical adjustment mechanisms are arranged between the sliding foot base 2 and the supporting foot 11. The vertical adjustment mechanisms include a vertical adjustment screw 3 and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap