Fully automatic wireless mold changing vehicle and system for presses

A fully automatic, press technology, applied in presses, metal processing equipment, forming tools, etc., can solve the problems of heavy molds, cumbersome operations, and occupation of crane resources, and achieve convenient use, simplified operation process, and improved safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in detail below in conjunction with accompanying drawing:

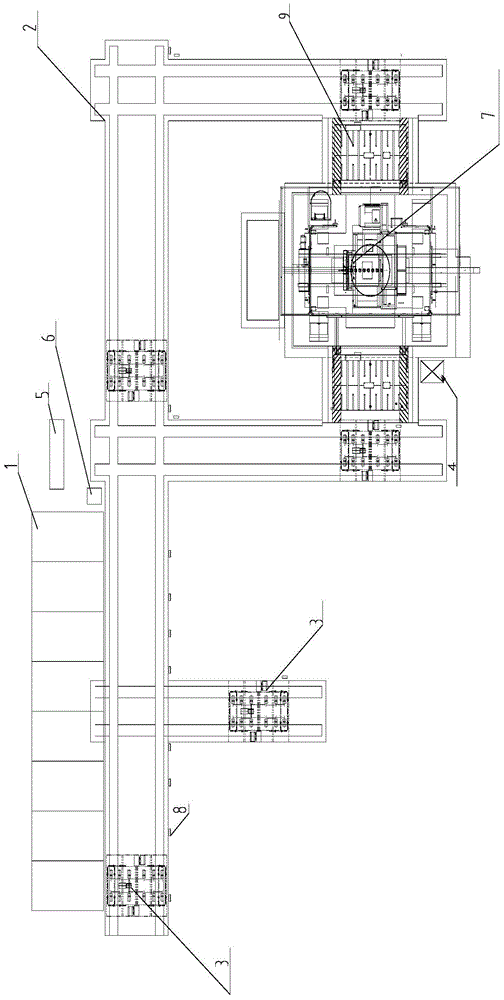

[0048] like figure 1 Shown: Multi-station automatic wireless mold changing system, including storage table 1, guide rail 2, mold changing car 3, punching machine operating platform 4, control cabinet 5, automatic charging device 6, punching machine 7, positioning detection board 8, The workbench 9, the mold changing car 3 can move horizontally and vertically along the guide rail, and an automatic charging device 6, a positioning detection plate 8 and a storage table 1 are installed on the side of the guide rail 2, the described mold changing car, automatic The charging device, the detection board and the storage platform are all controlled by a control cabinet 5, and a workbench 9 is installed on the punching machine 7, and a punching machine operating platform 4 is installed on one side thereof.

[0049] Figure 8(1)-Figure 8(4) As shown: the storage table 1 includes a supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com