Novel floating type disc shaped braking device

A brake device, floating technology, applied in hoisting device, brake type, brake parts, etc., can solve the problems of increasing the bending stress of the main shaft, increasing the cost of mine infrastructure, wasting alloy materials, etc., to achieve material cost saving and overall The effect of size reduction and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

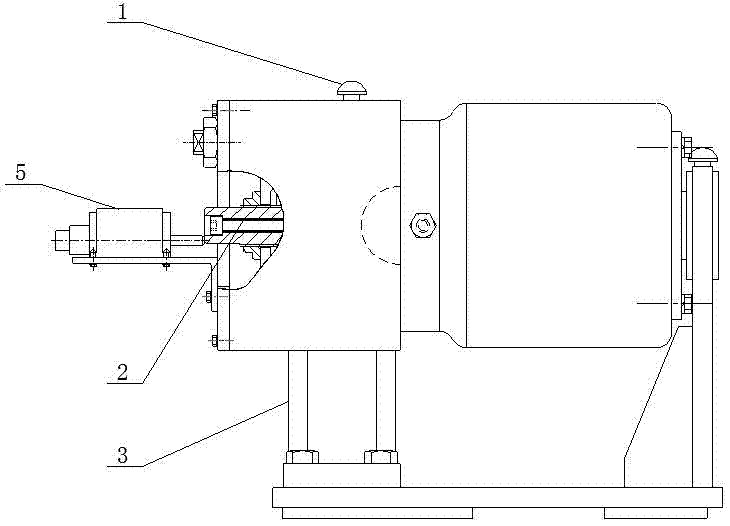

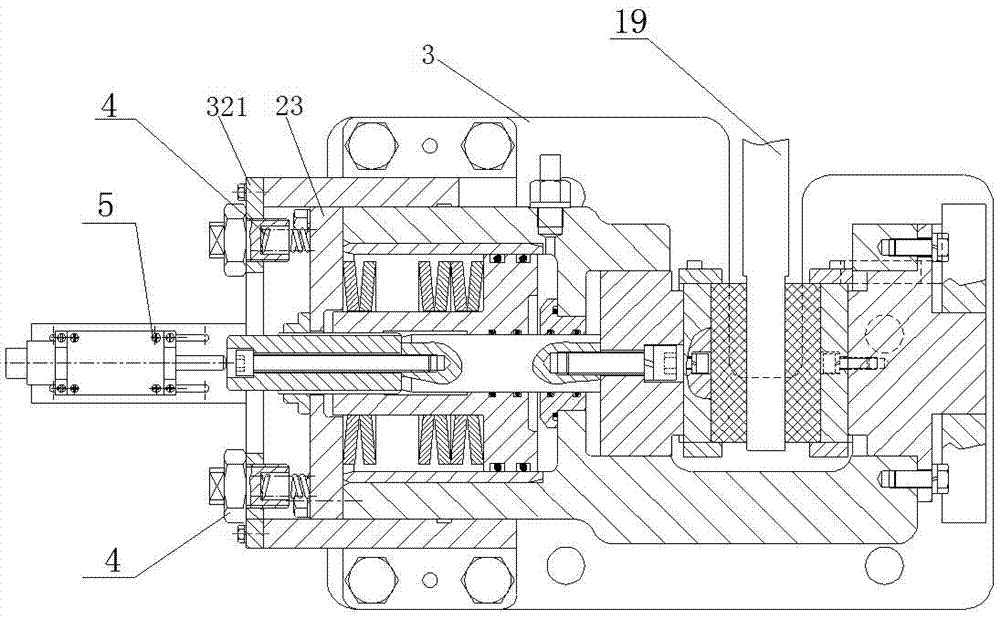

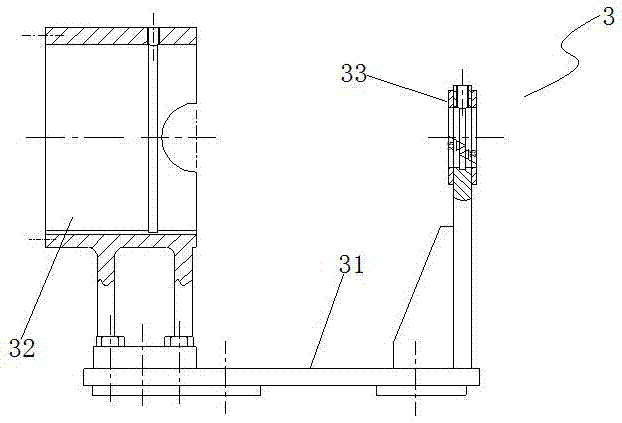

[0042] like Figure 1-10 As shown, a new type of floating disc brake device includes a support 3, a brake housing 7 that is sleeved in the support 3 and can move relative to the support 3 as a whole, and has a gap 9 on the brake housing 7. , The brake housing 7 is provided with a piston chamber 71 and a first guide platen chamber 72 .

[0043] A first through hole 73 is provided between the piston chamber 71 and the first guide platen chamber 72, and the two are connected.

[0044] The inner wall of the piston cylinder 71 is provided with a steel sleeve 14, the steel sleeve 14 is provided with a piston rod 13, and the piston rod 13 is sleeved with a disc spring 15.

[0045] The first guide platen cavity 72 is provided with a first guide platen 11, the first guide platen 11 is connected to the front end of the piston rod 13 through the connecting rod 22 through the first through hole 73, and the front end of the first guide platen 11 is fixed with a first A friction plate 20....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com