A kind of high-efficiency full-interface pump leaching method of rare earth roasted ore by acid method

A leaching and rare earth technology, applied in the field of hydrometallurgy, can solve the problems of equipment, labor, energy consumption, large area, long process flow, etc., and achieve the effect of improving the efficiency of the water leaching process and making the shell soft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

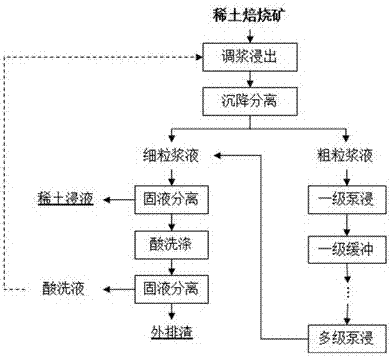

[0024] The acid-processed rare earth roasted ore and water were mixed according to the solid-to-liquid weight ratio of 1:6 and leached for 40 minutes, the leaching temperature was 25°C, and the pH value of the leaching slurry was 2.5. The leached slurry is separated by gravity settling to obtain fine-grained slurry and coarse-grained slurry. The coarse-grained slurry is leached by a 4-stage high-efficiency full-interface pump, combined with a 3-stage tank buffer vortex leaching, and the leached slurry is combined with the fine-grained slurry for solid-liquid separation. A 52.48g / l sulfuric acid rare earth feed solution and leaching residue were obtained, and the leaching residue was washed with dilute sulfuric acid. The pH value of the washing liquid was 0.3, and the dilute sulfuric acid was diluted with acid recovered from tail gas. The acid to slag solid-liquid weight ratio is 1:6, and the time is 10 minutes. 3.21g / l pickling solution and external slag were obtained by soli...

Embodiment 2

[0026] The hot roasted ore and water are mixed according to the solid-to-liquid weight ratio of 1:8, and the slurry is leached for 20 minutes. The leaching temperature is 38°C, and the pH value of the leaching slurry is 1.0~1.5. The leached slurry is separated by gravity settling to obtain fine-grained slurry and coarse-grained slurry. The coarse-grained slurry is leached by a 4-stage high-efficiency full-interface pump, combined with a 3-stage tank buffer vortex leaching, and the leached slurry is combined with the fine-grained slurry for solid-liquid separation. A 39.45g / l sulfuric acid rare earth feed solution and leaching residue were obtained, and the leaching residue was washed with dilute sulfuric acid, the pH of the washing liquid was 1.0, and the dilute sulfuric acid was diluted with acid recovered from tail gas. The acid to slag solid-liquid weight ratio is 1:8, and the time is 20 minutes. The pickling solution with REO content of 1.78g / l and the external slag were ...

Embodiment 3

[0028] The hot roasted ore and water were mixed according to the solid-to-liquid weight ratio of 1:7 and leached for 40 minutes, the leaching temperature was 39.5°C, and the pH value of the leaching slurry was 1.0-1.5. The leached slurry is separated by gravity settling to obtain fine-grained slurry and coarse-grained slurry. The coarse-grained slurry is leached by a 3-stage high-efficiency full-interface pump, combined with the 2-stage tank buffer eddy current leaching, and the leached slurry is combined with the fine-grained slurry for solid-liquid separation. A 44.89g / l sulfuric acid rare earth feed solution and leaching slag were obtained, and the leaching slag was washed with dilute sulfuric acid. The pH value of the washing liquid was 0.5~1.0, and the dilute sulfuric acid was prepared from concentrated sulfuric acid. The acid to slag solid-liquid weight ratio is 1:10, and the time is 20 minutes. The pickling liquid with REO content of 1.5g / l and the external slag were o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com