High-strength polyester silk drafting device

A technology of polyester high-strength yarn and drafting device, which is applied in the directions of drawing spinning, filament generation, filament/thread forming, etc., can solve the problems of low relative fiber strength, decreased drafting performance, uneven fiber temperature, etc. Achieve the effects of improved drafting performance, increased spinning speed, and reduced equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

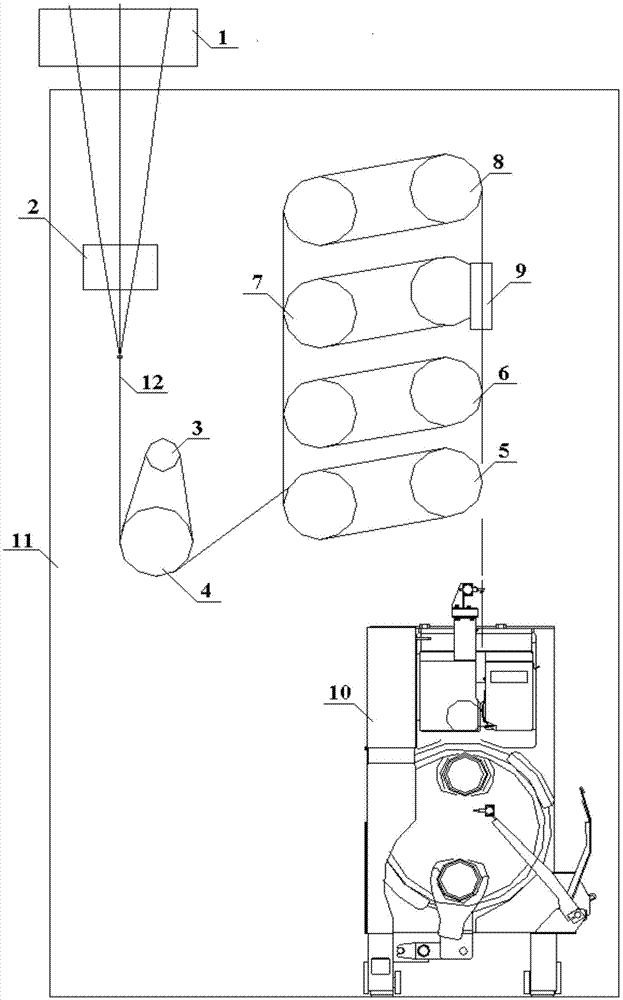

[0024] The embodiment of the present application provides a polyester high-strength yarn drawing device to solve the problem of uneven fiber temperature in the prior art, decreased drawing performance, low spinning speed, low relative fiber strength, poor product quality, and high raw material consumption. The problem of high energy consumption of equipment; it has achieved the technical effect of improving drafting performance, increasing spinning speed, increasing relative strength of fibers, improving product quality, and reducing raw material consumption and equipment energy consumption.

[0025] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0026] A polyester high-strength yarn drawing device, comprising: an oiling device, a pre-netting device, a feeding separation roller, a feeding heating roller, a first group of hot drawing rollers, a second group of hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com