Operation Technology of Shore-supported Mud Station System for Offshore Drilling

A technology for marine drilling and operation technology, applied in the field of marine drilling, can solve the problems of inability to move, long time required for station construction, single function, etc., to improve reliability and stability, simplify equipment operation and maintenance, and achieve significant economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, the implementation process of the present invention will be further described:

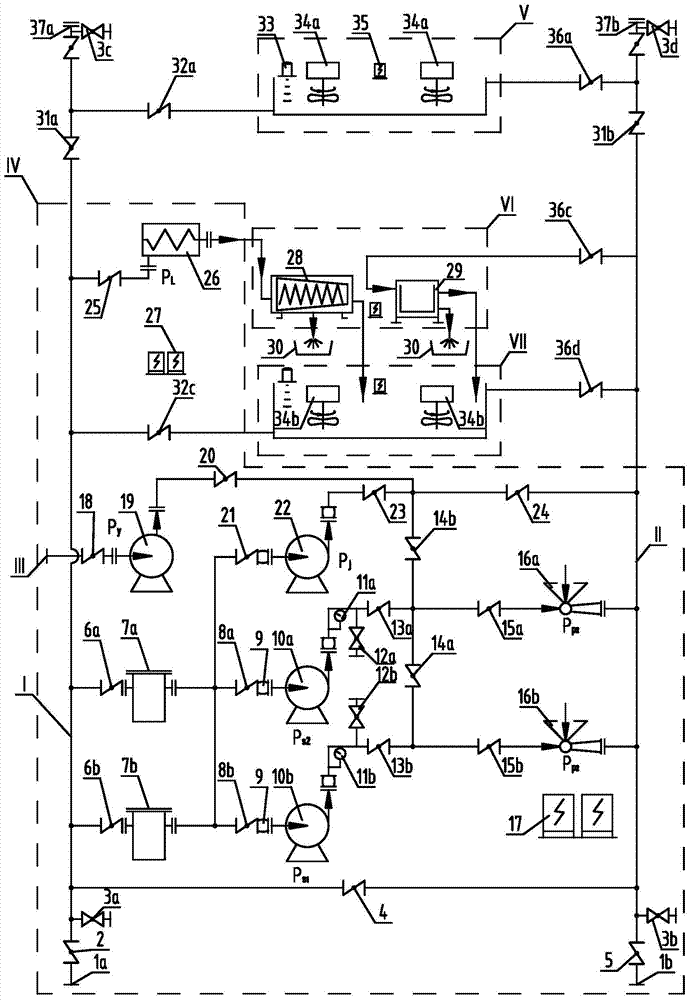

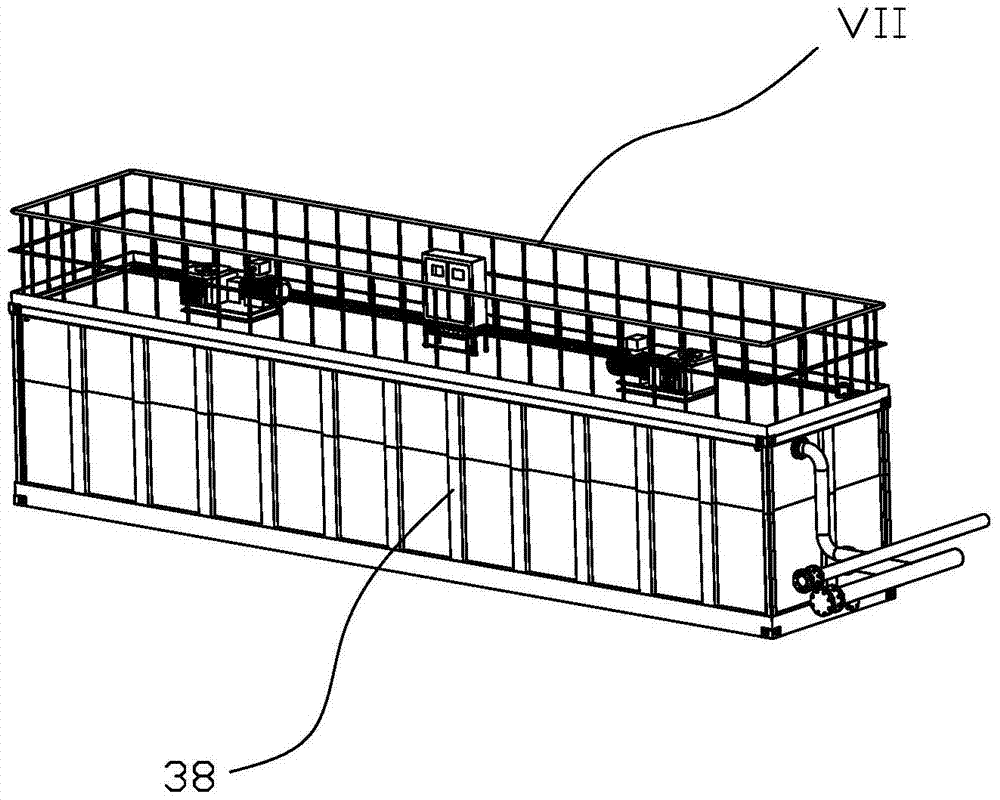

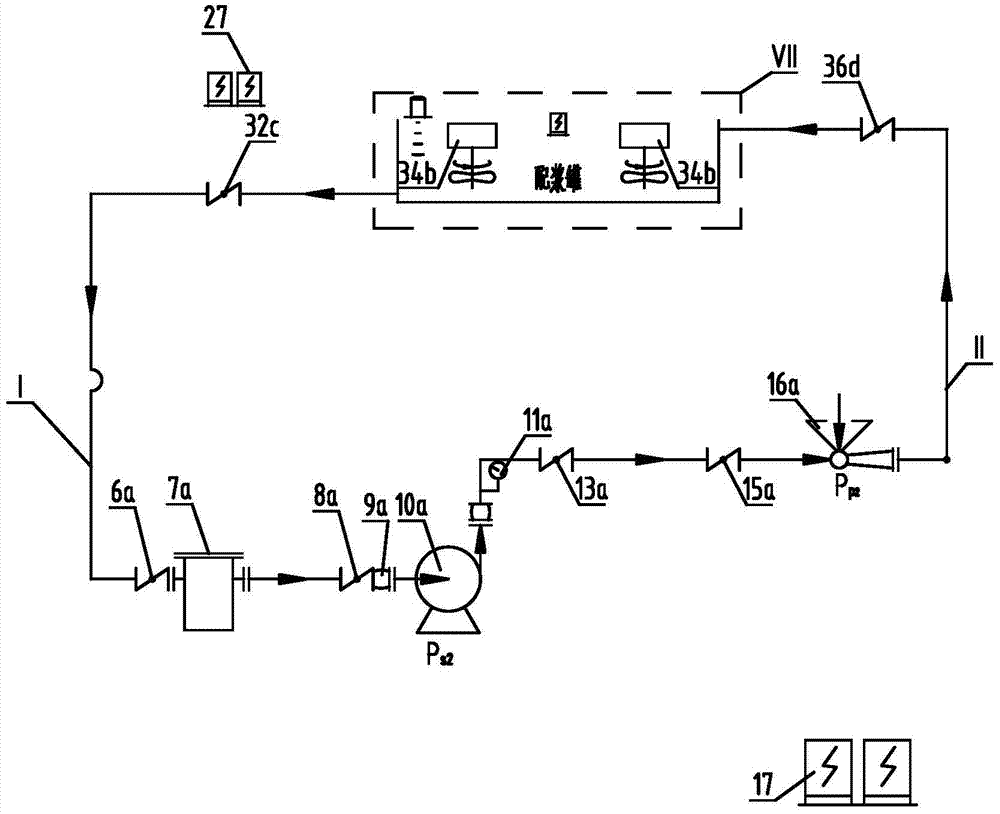

[0048] The mud station system targeted by the present invention consists of mobile pump skid integrated unit IV, mobile slurry tank integrated unit VII, mobile storage tank integrated unit V, waste liquid treatment skid integrated unit VI, Ⅰ-main liquid inlet pipeline, Ⅱ-main outlet Liquid pipeline, Ⅲ-white oil unloading pipeline and corresponding control system.

[0049] Such as figure 1 As shown, the mobile pump skid integration unit IV mainly integrates the first sand pump 10a, the second sand pump 10b, the first mixing funnel 15a, the second mixing funnel 15b, the shear pump 22, the white oil pump 19, the screw pump 26, etc. Fluid conveying equipment can convey different media according to different process requirements such as slurry mixing, storage, and transfer, among which the first sand pump 10a and the second sand pump 10b are mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com