A control loop of a loader working device

A working device and control circuit technology, which is applied in the field of hydraulic systems, can solve the problems of reduced strength, large space occupation, and easy fatigue of the structure, and achieve the effects of improving operating efficiency, increasing lifting speed, and requiring less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

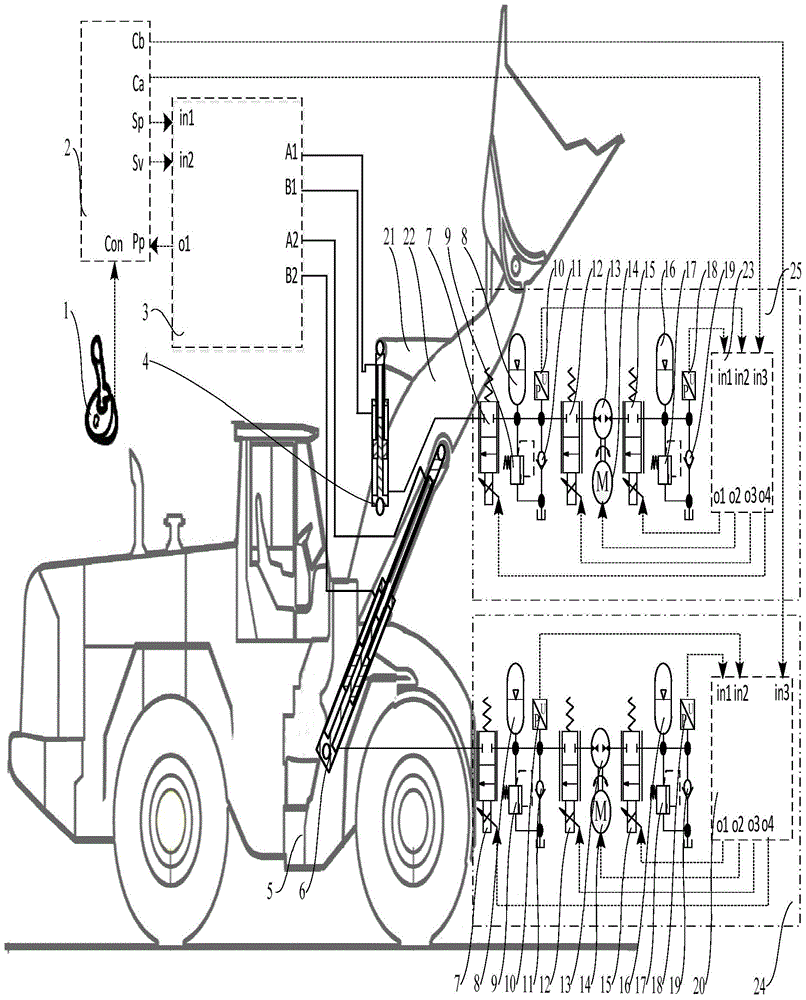

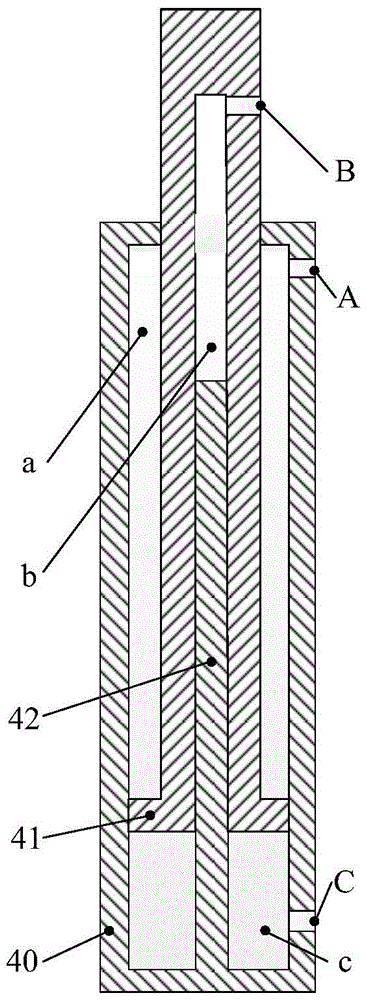

[0034] Embodiment 1: a control loop of a loader working device provided by the present invention, such as figure 1 As shown, it includes: the working mechanism of the loader, the driving circuit 3 of the working device, the control handle 1, and the controller 2, wherein the working mechanism of the loader includes an underframe 5, a boom 22, a bucket and a tipping mechanism 21. The invention also includes: the boom hydraulic cylinder 6 is a hydraulic cylinder with three cavities, the bucket hydraulic cylinder 4 is a hydraulic cylinder with three cavities, the recovery cavity of the boom hydraulic cylinder 6 is connected to the boom recovery hydraulic system 24, The recovery chamber of the dump bucket hydraulic cylinder 4 is connected to the dump bucket recovery hydraulic system 25 . Boom recovery hydraulic system and tipping bucket recovery hydraulic system have the same structure, including: proportional valve 7, balance accumulator 8, balance chamber overflow valve 9, balan...

Embodiment 2

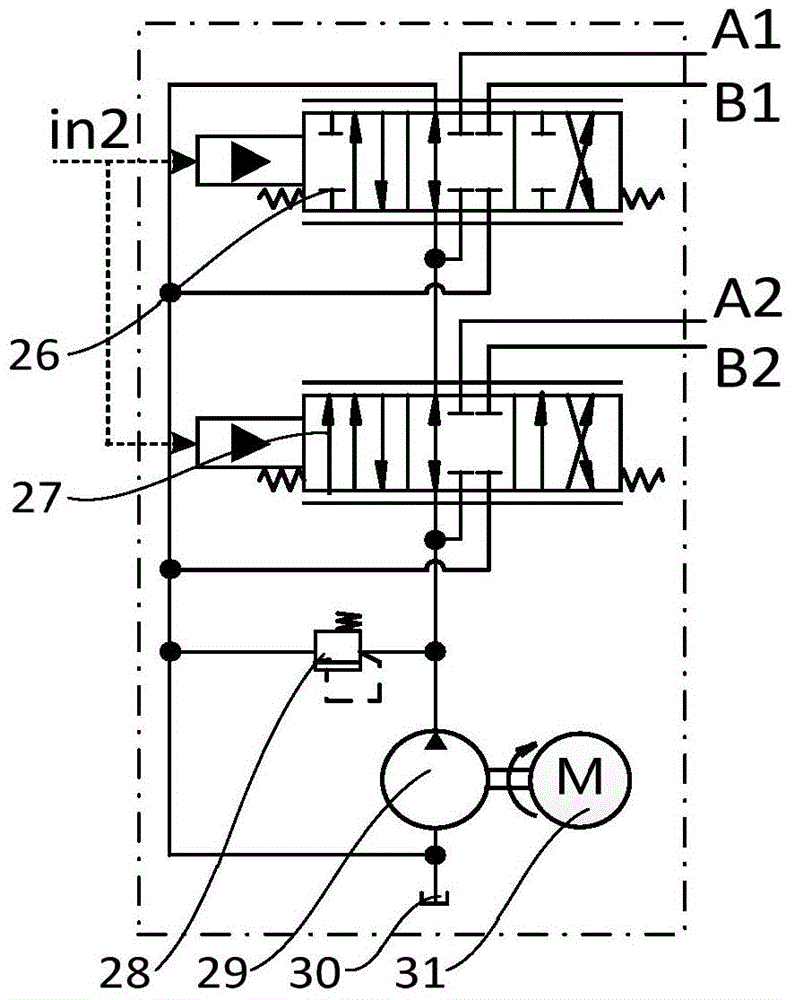

[0047] Embodiment 2: The difference between the structure of this embodiment and Embodiment 1 is that the driving circuit of the work device adopts another open hydraulic circuit, that is, as Figure 4 Closed-center variable pump load-sensing hydraulic system shown.

[0048]The load-sensitive hydraulic system of the neutral closed variable pump includes a bucket control valve 26, a boom control valve 27, an overflow valve 28, a main pump 29, an oil tank 30, a main engine 31, a pressure sensor 32, and a pressure signal controller 33. Wherein, the output shaft of the main engine 31 is connected with the main shaft of the main pump 29, the oil suction port of the main pump 29 is connected with the oil tank 30, the oil outlet of the main pump 29 is connected with the high pressure port of the relief valve 28 and the oil inlet of the boom control valve 27 The oil outlet of the main pump 29 is connected to the inlet of the dump control valve 26 through the neutral channel of the bo...

Embodiment 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the driving circuit of the working device adopts the third open hydraulic circuit, that is, as Figure 5 Inlet and outlet independently controlled hydraulic system shown.

[0050] Import and export independent control hydraulic system includes overflow valve 28, main pump 29, oil tank 30, main engine 31, pressure sensor 32, pressure signal controller 33, dump bucket regeneration control valve 3501, dump bucket hydraulic cylinder extension cavity oil inlet valve 3502 , Oil return valve 3503 for tipping bucket hydraulic cylinder extension cavity, oil inlet valve for tipping bucket hydraulic cylinder retraction cavity 3504, oil return valve for tipping bucket hydraulic cylinder retraction cavity 3505, boom regeneration control valve 3506, boom hydraulic cylinder extension cavity oil inlet Valve 3507, the oil return valve 3508 of the extended chamber of the boom hydraulic cylinder, the oil inlet v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com