Circuit board type net lamp and manufacturing method thereof

A manufacturing method and circuit board technology, which can be applied to lampshades, special patterns, printed circuits connected with non-printed electrical components, etc. and maintenance inconvenience, to achieve better decorative effect, easy mass production, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment. The embodiments are only used to illustrate the technical solution of the present invention, and do not constitute a limitation to the protection scope of the present invention.

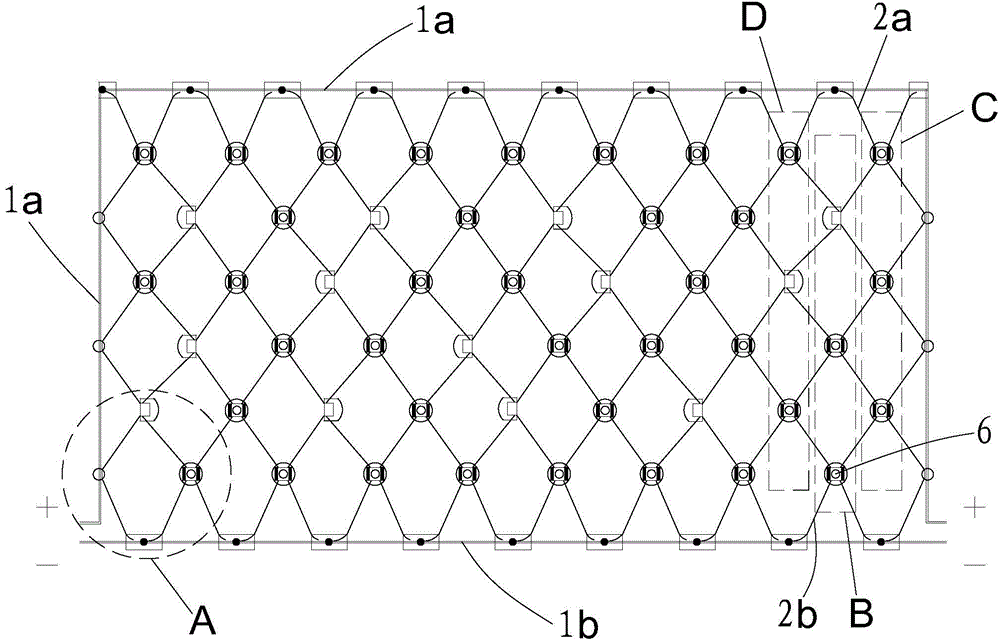

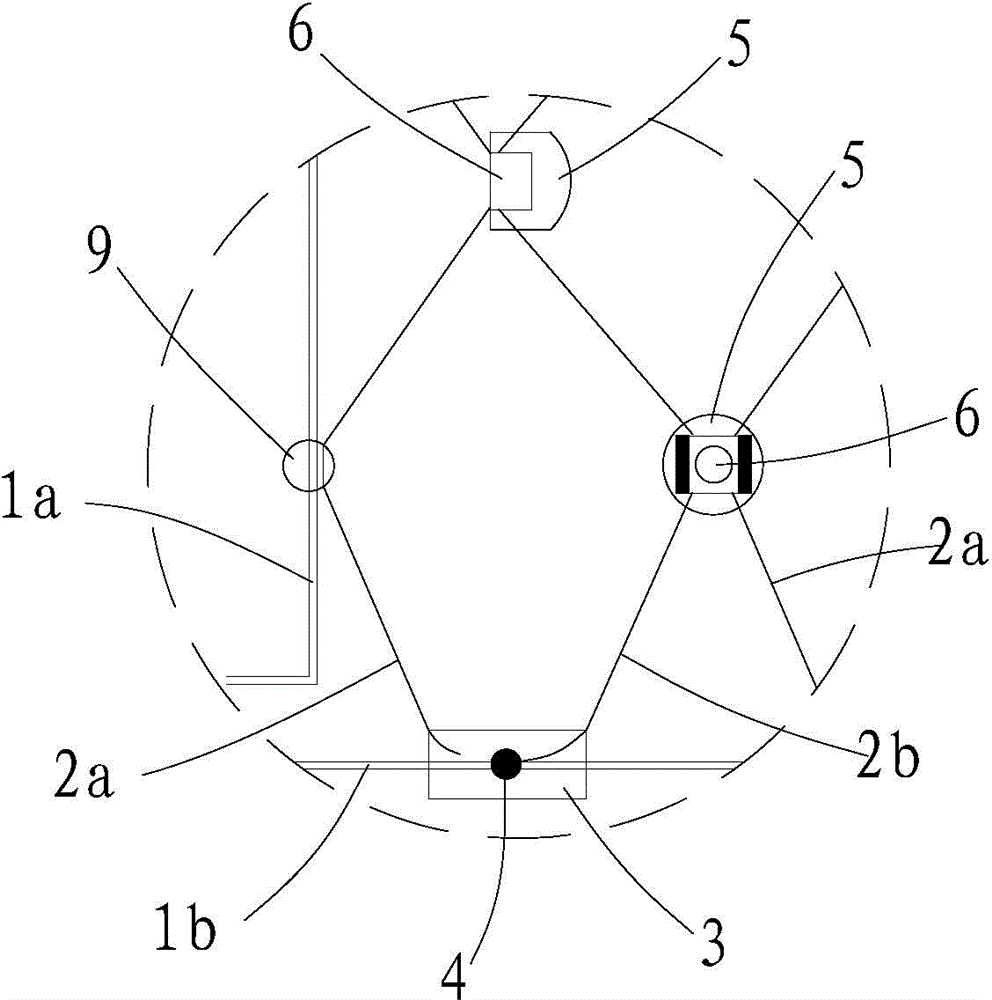

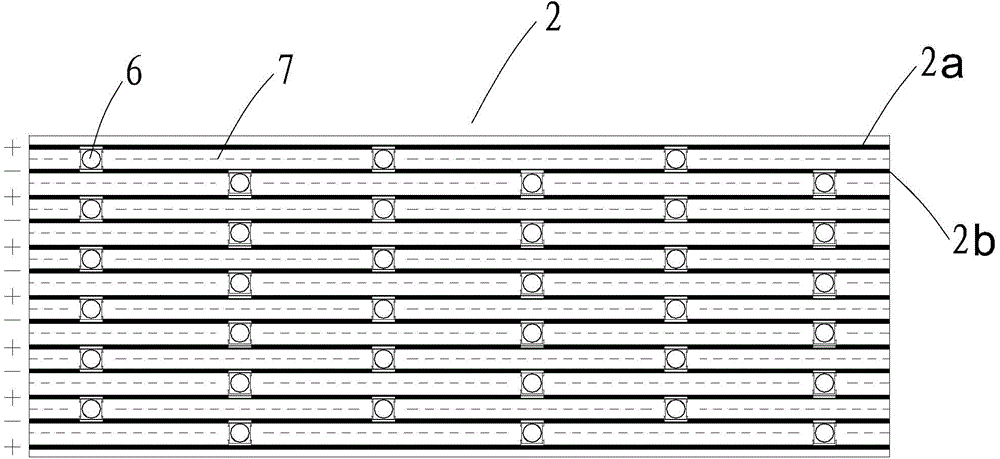

[0035] refer to figure 1 , figure 2 , Figure 5 , Image 6 , Figure 7 , the circuit board type net lamp of the present invention, comprises positive pole power supply main line 1a, negative pole power supply main line 1b and light source; Positive pole, negative pole power supply main line surround the outer outline of net lamp; Described light source comprises flexible circuit board and is welded on the flexible circuit board The flexible circuit board described in SMD LED 6 is a non-corrosive circuit board, which includes two positive and negative power lines 2a, 2b made of flat metal wires made of rolled metal wires and attached to the positive, The insulating film on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com