Efficient heat exchange assembly for refrigeration equipment

A technology for heat exchange components and refrigeration equipment, applied in refrigeration components, refrigerators, refrigeration and liquefaction, etc., can solve the problems of complex structure, difficult maintenance and replacement, easy leakage, etc. leak-prone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

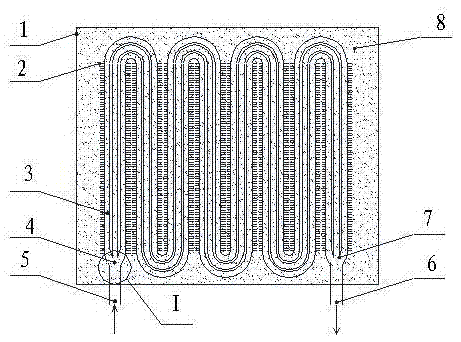

[0017] Such as figure 1 , figure 2 As shown, a high-efficiency heat exchange assembly for refrigeration equipment includes a casing (1) and a conduit assembly (4) arranged in the casing (1), and a gap between the casing (1) and the conduit assembly (4) Filled with copper shavings with a porosity of 60%, the conduit assembly (4) is composed of three pure copper sub-conduits (3) connected in parallel, each sub-conduit (3) is evenly welded with multiple austenite Metal blocks (2) made of stainless steel, the interval between adjacent metal blocks (2) is 20mm, and the two branch conduits (3) are located at the refrigerant liquid inlet (5) and the refrigerant liquid outlet (6). The connection is combined by welding, and the welding joint (7) is sealed with ZP special sealing grease.

[0018] The welding method and the bonding method are all existing technologies in the field of electrical appliances, and will not be described in detail, the same below.

Embodiment 2

[0020] A high-efficiency heat exchange assembly for refrigeration equipment, comprising a shell (1) and a conduit assembly (4) arranged in the shell (1), the gap between the shell 1 and the conduit assembly 4 is filled with a porosity of 60% aluminum chips, the conduit assembly (4) is formed by parallel connection of two pure copper branch conduits (3) ( figure 1 , figure 2 Shown are three sub-conduits (3) connected in parallel), each sub-conduit (3) is uniformly bonded and fixed with a plurality of austenitic stainless steel metal blocks (2), between adjacent metal blocks (2) The distance between the two sub-pipes (3) is combined and communicated at the refrigerant liquid inlet (5) and the refrigerant liquid outlet (6) by welding, and the welded joint (7) adopts ZP special Sealant seal.

Embodiment 3

[0022] A high-efficiency heat exchange assembly for refrigeration equipment, comprising a casing (1) and a conduit assembly (4) arranged in the casing (1), and gaps are filled between the casing (1) and the conduit assembly (4) rate of 40% copper filings, the conduit assembly (4) is formed by parallel connection of five pure copper branch conduits (3) ( figure 1 , figure 2 Shown are three sub-conduits (3) connected in parallel), each sub-conduit (3) is uniformly welded with a plurality of austenitic stainless steel metal blocks (2), and the interval between adjacent metal blocks (2) The five sub-pipes 3 are combined and communicated at the refrigerant liquid inlet (5) and the refrigerant liquid outlet (6) by welding, and the welded joints (7) are sealed with ZP special sealing grease.

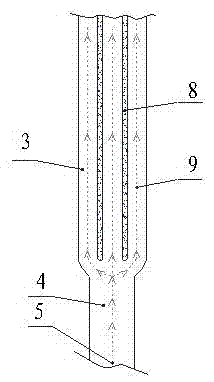

[0023] Working principle: the refrigerant flow (9) presses figure 2 The path shown flows in through the refrigerant inlet (5), splits the flow into each sub-conduit (3), conducts heat to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com