Automatic device for measuring setting time of concrete mixture

A coagulation time and measuring device technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems that the pressurization time cannot be accurately guaranteed, the equipment does not achieve automatic recording, and the accuracy of recording cannot be guaranteed, so as to improve the detection work Quality, elimination of human factors, intuitive reading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

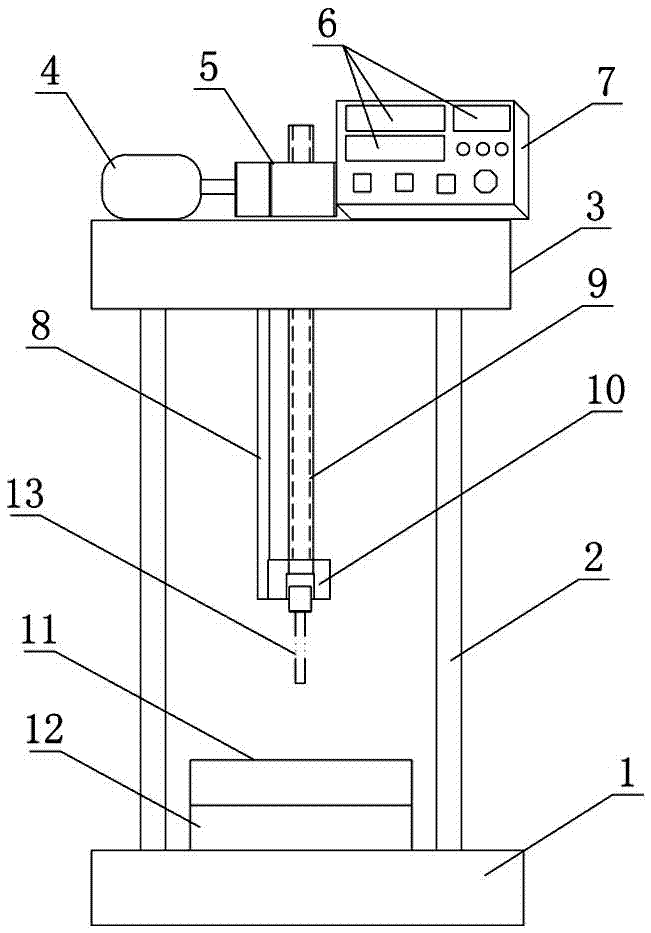

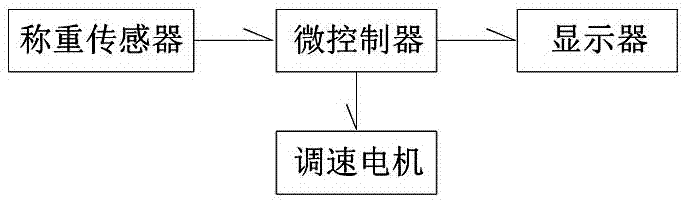

[0017] Such as figure 1 , 2 As shown, the automatic concrete mixture setting time measuring device of the present invention includes a machine base 1, a door-shaped frame 2 fixed on the machine base 1, and a speed-regulating motor is arranged on the crossbeam 3 of the door-shaped frame 2 4. The worm gear pair 5 driven by the speed-regulating motor 4 and the microcontroller 7 with the display 6; the output control end of the microcontroller 7 is connected with the control input end of the speed-regulating motor 4, and the data output terminal of the microcontroller 7 Connect with the data signal input end of display 6; On the crossbeam 3 of door glyph frame 2, travel scale 8 is arranged vertically downwards, and the vertical leading screw 9 driven lifting by worm gear pair 5, the lower end of vertical leading screw 9 is provided with Stylus mounting base 10; the base 1 is located directly below the stylus mounting base 10 and is provided with a sample table 11 and a load cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com