Liquid level measurement device and gas intrusive liquid level measurement system thereof

A liquid level measurement device and liquid level measurement technology are applied in control/regulation systems, liquid level indicators displayed through pressure measurement, and electrical program control, etc., which can solve the problem of poor linearity of liquid level gauge display trends, easy oxygen leakage, and medium Blockage and other problems, to achieve the effect of saving non-renewable energy, saving production costs, and preventing personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

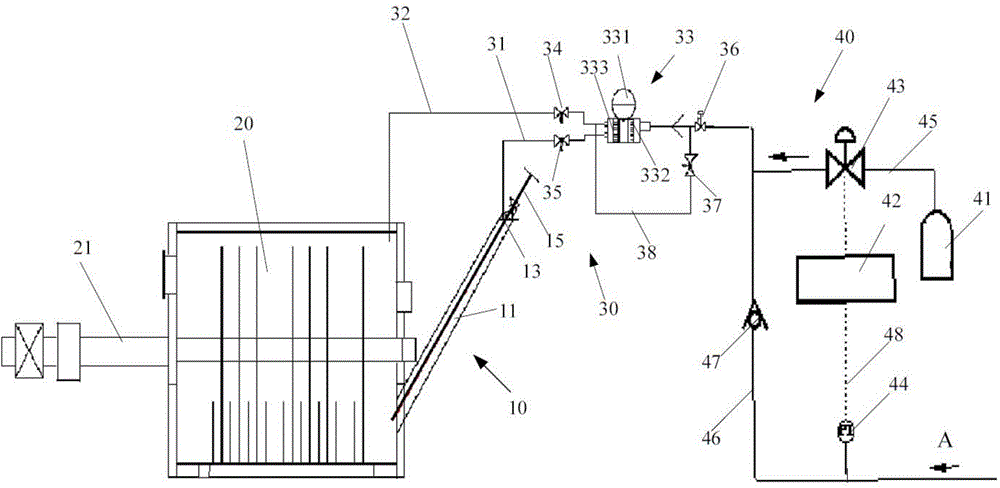

[0044] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

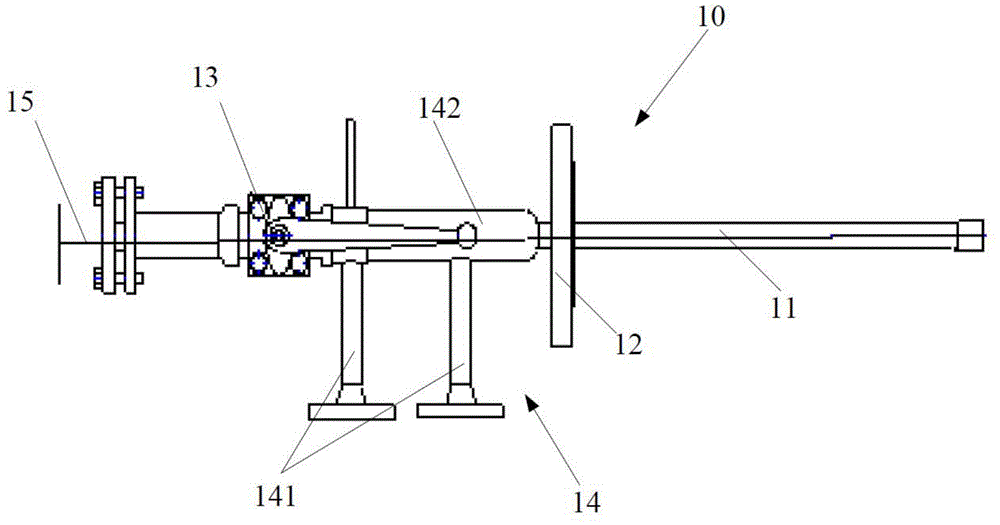

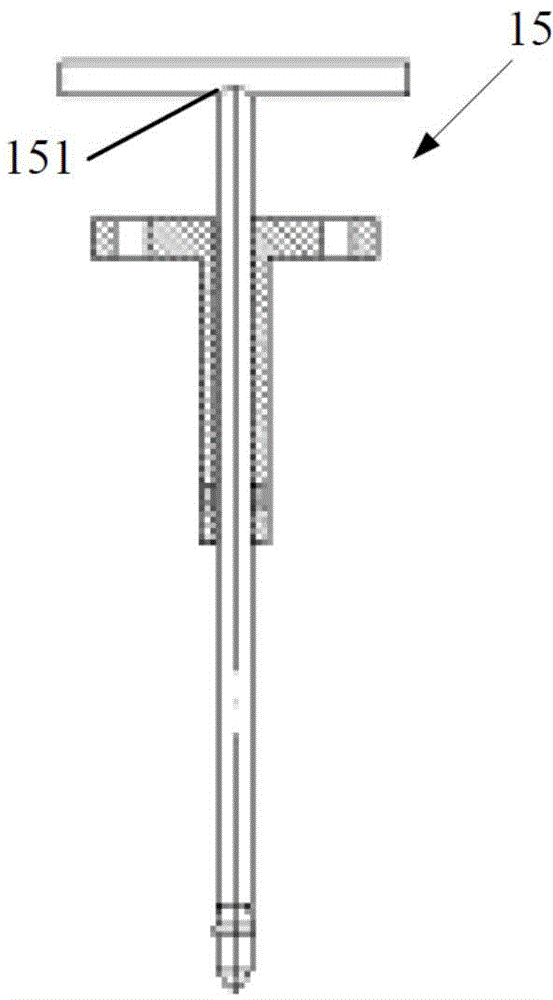

[0045] figure 1 It is a structural schematic diagram of the liquid level measuring device of the present invention. like figure 1 As shown, the liquid level measuring device 10 of the present invention includes a liquid level gauge body, and the liquid level gauge body includes a body measuring tube 11, a connecting flange 12 and a high-temperature cock valve 13, and the connecting flange 12 is affixed to the body measuring tube 11 One end, for example, is fixed by welding. The high-temperature plug valve 13 is integrated with the main body measuring pipe 11 through the connecting flange 12 , and a jacketed heating pipe 14 is arranged between the high-temperature plug valve 13 and the connecting flange 12 . In this embodiment, the body measuring tube 11 , the connecting flange 12 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com