Test system and method for intelligent product production

A technology for production testing and intelligent products, applied in the direction of response error generation, redundant code error detection, etc., can solve the problems of long cycle, low efficiency of intelligent product testing, waste of time, etc., and achieve the effect of reducing cycle and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

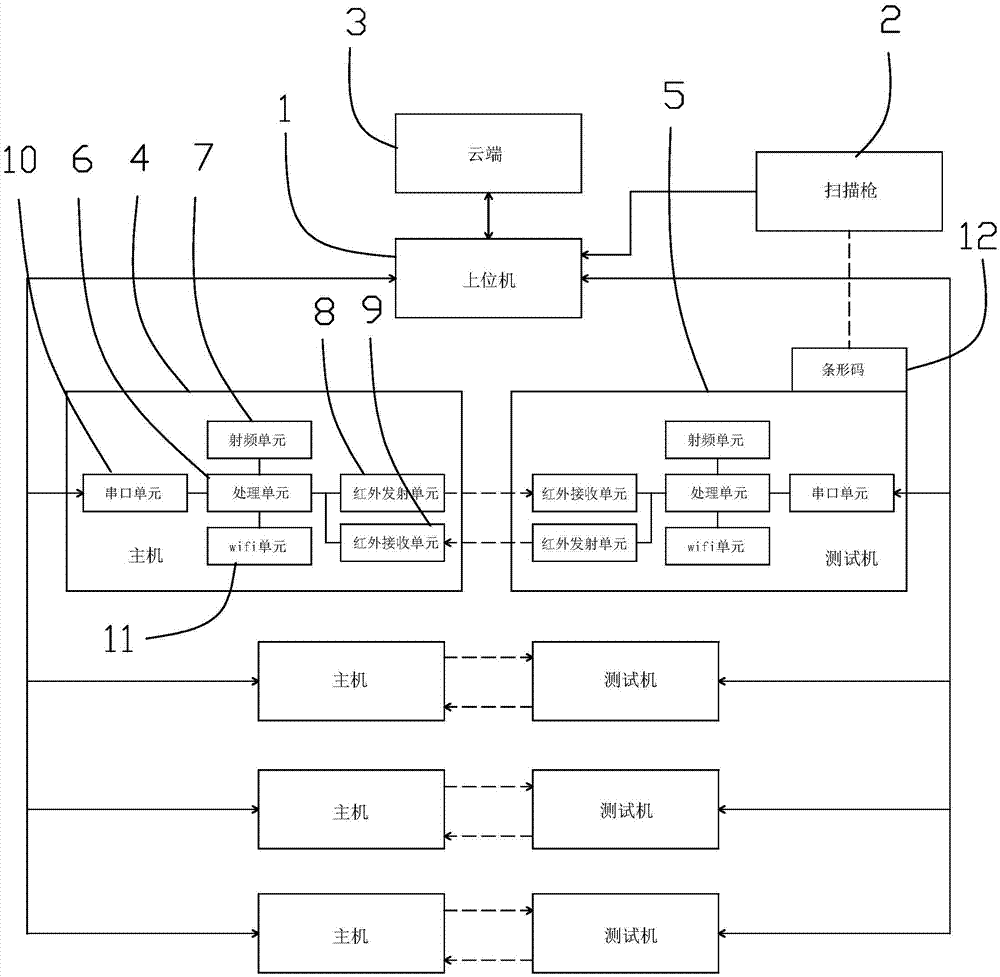

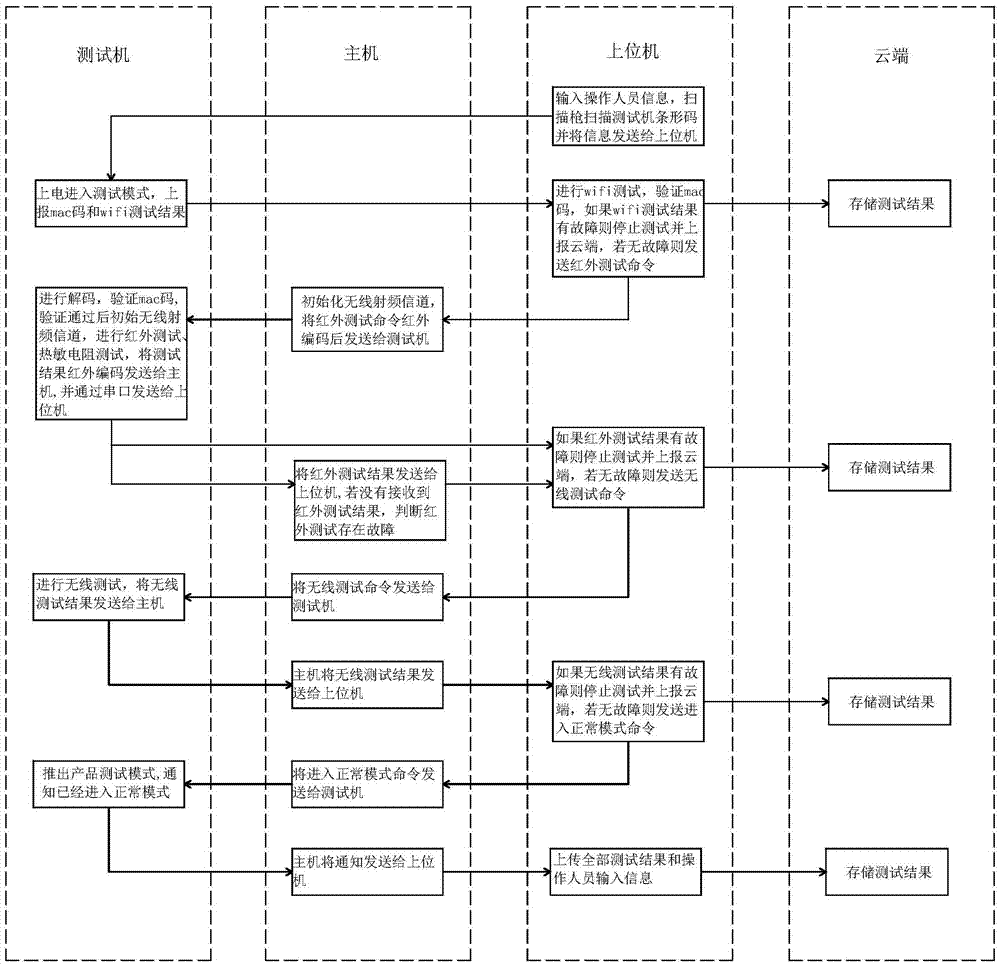

[0030] In this embodiment, a production test system for smart products, such as figure 1 As shown, it includes a host computer 1, a scanning gun 2, several hosts 4, and several testing machines 5 corresponding to the hosts. In this embodiment, 4 hosts and testing machines are taken as an example. The scanning gun is connected to the host computer, the host computer and the testing machine are respectively connected to the host computer through serial ports, and the host computer and the testing machine are connected via infrared. The testing machine is provided with a barcode 12 corresponding to its verification information. The system also includes a cloud 3, which is connected to the host computer through a network.

[0031] Both the host 4 and the testing machine 5 include an infrared receiving unit 9, an infrared emitting unit 8, a processing unit 6, a wifi unit 11, a serial port unit 10 and a radio frequency unit 7, an infrared receiving unit, an infrared emitting unit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com