High Frequency Resolver

A resolver, high-frequency technology, applied in the direction of transformers, transformer/inductor cores, transformer/inductor components, etc., can solve problems such as reducing the coupling distance of transformers, improve flatness and consistency, and improve efficiency , the effect of improving the coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] On the basis of the embodiments of the present invention, this embodiment provides a specific embodiment of a high-frequency rotary transformer, such as Figure 1 to Figure 5 shown.

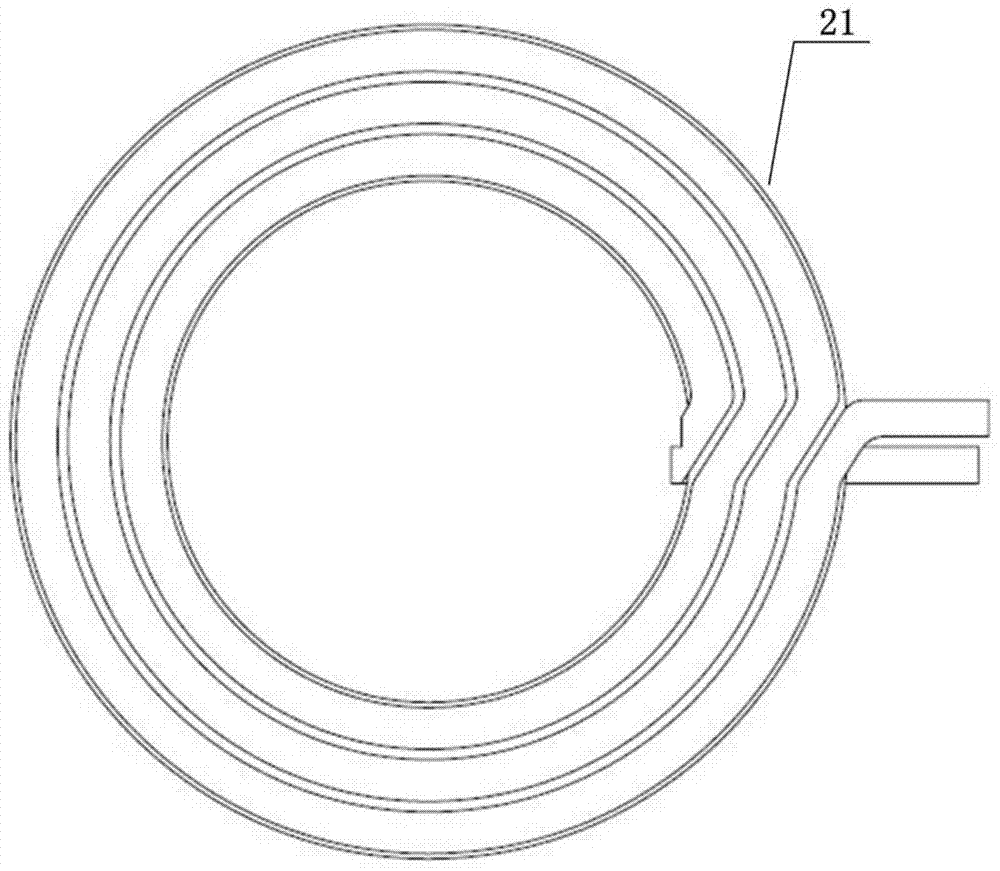

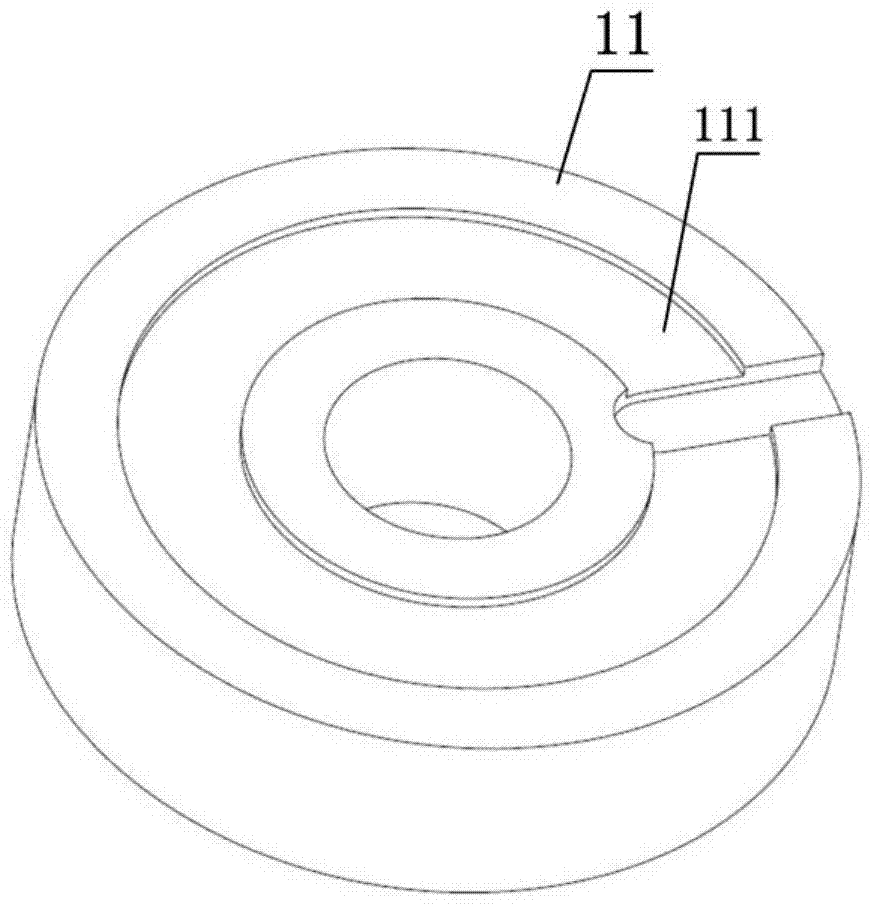

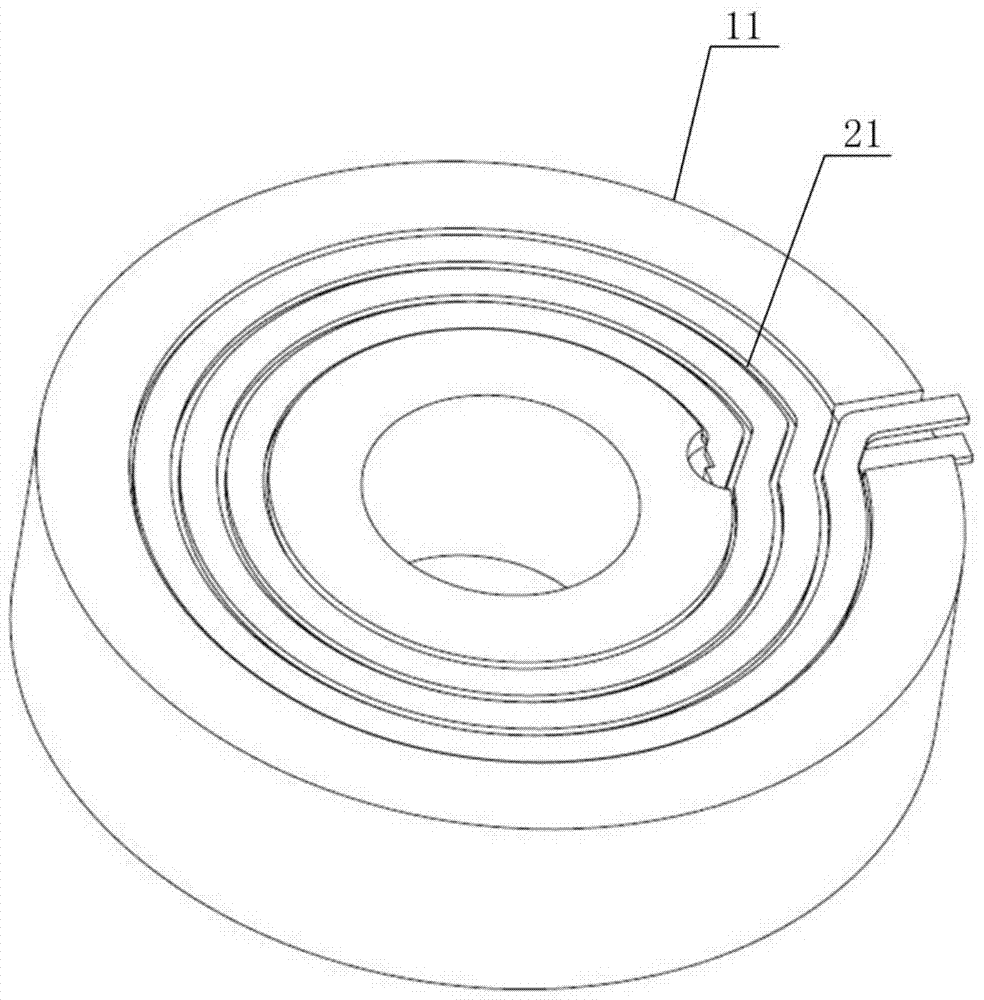

[0050] Such as figure 1 As shown, the first printed circuit board drawing coil 21 and the second printed circuit board drawing coil 22 are planar. Such as figure 2 with image 3 As shown, the first magnetic core 11 and the second magnetic core 12 are both hollow columns, and the fixed shaft (not shown in the figure) of the first magnetic core 11 is fixedly installed in the hollow structure of the first magnetic core 11, and the fixed shaft The second magnetic core 12 is slidably connected to the second magnetic core 12 through the bearing, and the second magnetic core 12 rotates around the fixed axis of the first magnetic core 11 through the bearing, that is, the second magnetic core 12 rotates around the central axis of the first magnetic core 11 . The first magnetic core 11 is provi...

Embodiment 2

[0056] On the basis of the embodiments of the present invention, this embodiment provides a specific embodiment of a high-frequency rotary transformer, such as Figure 6 to Figure 8 shown.

[0057] Such as Image 6 with Figure 7 As shown, the first printed circuit board drawing coil 21 and the second printed circuit board drawing coil 22 are all crimped in a hollow cylindrical shape; Figure 8 As shown, the first magnetic core 11 is in the shape of a cylinder, the first printed circuit board drawing coil 21 is sleeved on the outside of the first magnetic core 11 in parallel with the radial direction of the first magnetic core 11, and the second magnetic core 12 is provided with a housing The cylindrical groove of the first magnetic core 11 , the second printed circuit board draws the coil 22 on the surface of the cylindrical groove, and the second magnetic core 12 rotates around the central axis of the first magnetic core 11 .

[0058] In this embodiment, the embedded inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com