Substrate installation platform, plasma processing device, and operation method for plasma processing device

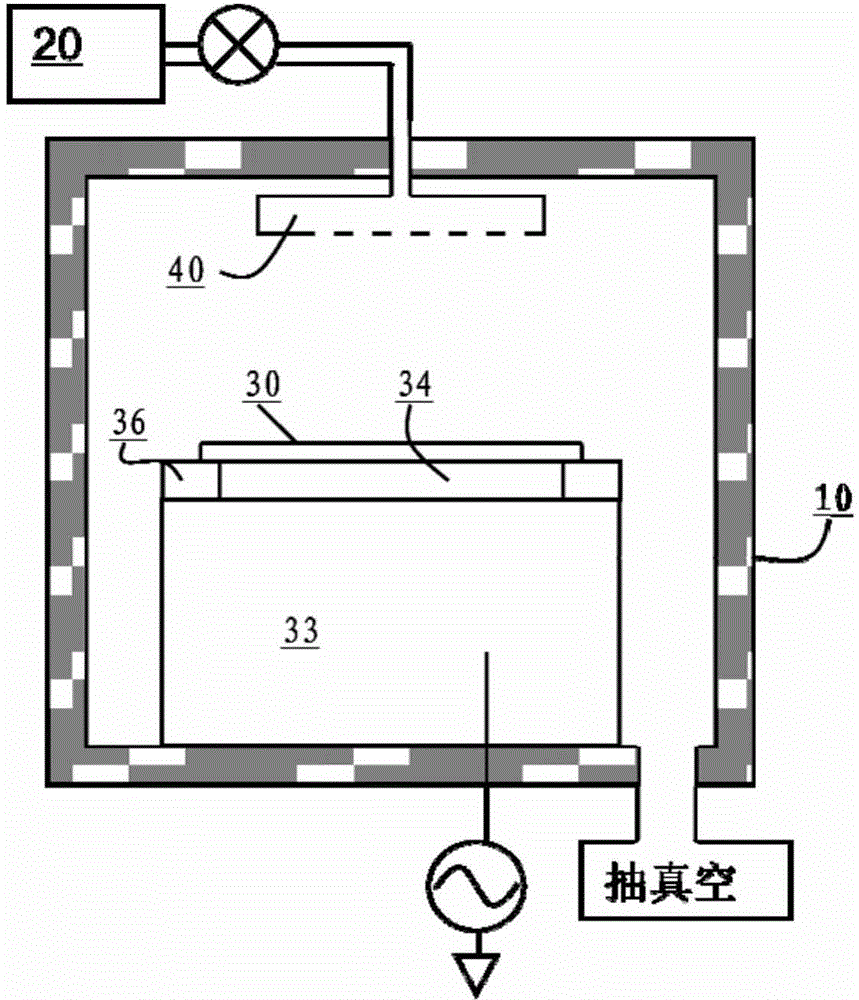

A technology for mounting platforms and processing devices, used in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., and can solve problems such as failure, substrate processing effect is different from the central area, damage to electrostatic chucks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

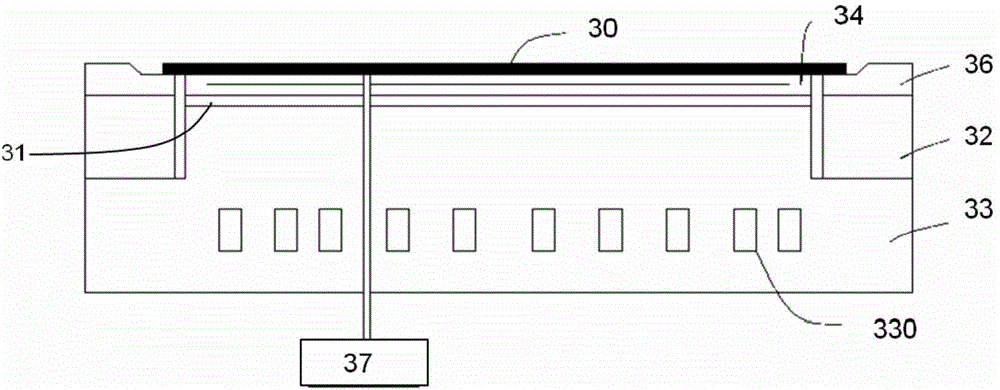

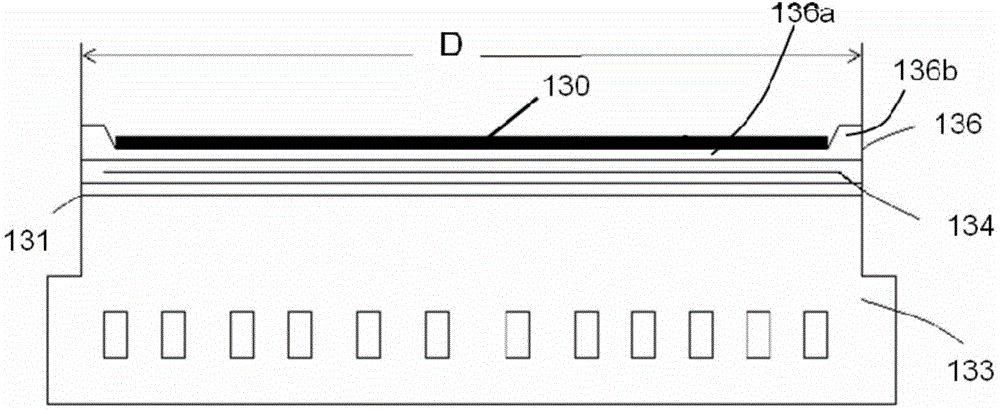

[0018] The present invention aims to solve the inhomogeneity of temperature in different regions of the substrate during the plasma treatment process, and at the same time prevent the side wall of the electrostatic chuck 34 on the back of the substrate from being corroded. An electrostatic chuck provides temperature control of the tray. Such as image 3 Shown is the first embodiment of the present invention, an adhesive layer 131 is included above the base 133 , an electrostatic chuck 134 is included above the adhesive layer 131 , and a tray 136 of the present invention is fixed above the electrostatic chuck. The tray 136 of the present invention includes a flat plate portion 136a and a raised portion 136b, wherein the raised portion 136b and the flat plate portion 136a are made of insulating materials such as SiO2, Al2O3, AlN, etc., and the upper surface of the raised portion 136b is on the main body material of the insulating material A layer of semiconductor material such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com