Sensor and assembly methods thereof

An assembly method and a sensor technology, which are applied in the field of sensing, can solve problems affecting reliability, large height difference between lead plate pads and chip pads, and lead wire lengthening, etc., to achieve improved reliability, simple and compact structure, and shortened length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

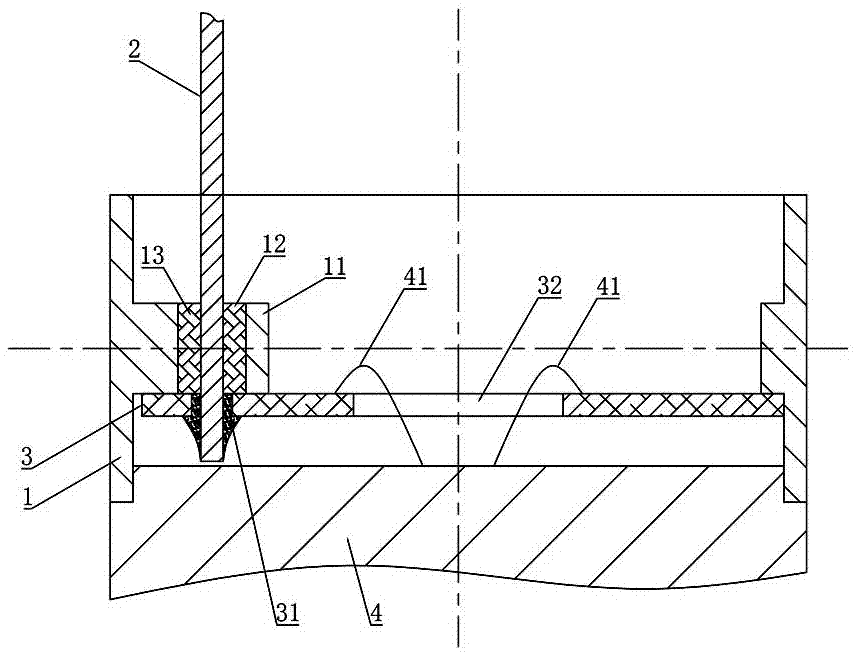

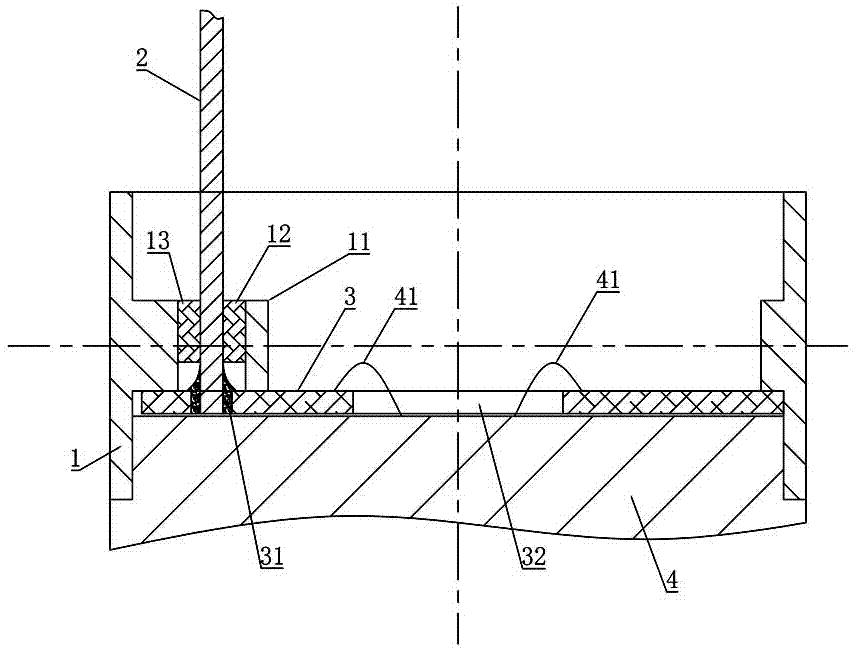

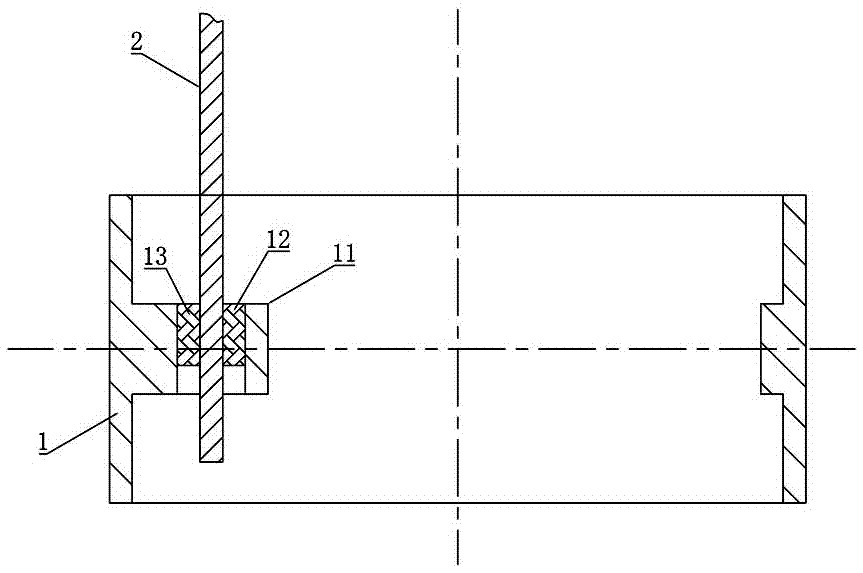

[0033] Such as Figure 3 to Figure 5 As shown, the assembly method of the sensor of the embodiment of the present invention includes the following steps:

[0034] S01, start, fill the upper part of the lead pin hole 12 on the protruding ring 11 of the inner wall of the lead bracket 1 with an insulating layer 13 and fix the lead pin 2 in the lead pin hole 12;

[0035] S02. Assemble the lead plate 3 to the inside of the lead frame 1 and contact the lower surface of the lead frame 1. At this time, the lower part of the lead pin 2 is inserted into the welding hole 31 of the lead plate 3 and its lower end surface is in contact with the lower surface of the lead plate 3. The surface is even, and then the lead plate 3 is welded to the lead pin 2, and the solder joint is extended to the lower part of the lead pin hole 12. Specifically, spot welding can be used to weld the lower surface of the lead plate 3, and the solder liquid It is left to the upper part of the lead plate 3, that i...

Embodiment 2

[0039] The assembly method of the sensor of the embodiment of the present invention comprises the following steps:

[0040] S01, start, insert the lower part of the lead pin 2 into the welding hole 31 of the lead plate 3, then weld the lead plate 3 and the lead pin 2 on the upper surface of the lead plate 3, and ensure that the lower end surface of the lead pin 2 is in contact with the lead wire The lower surface of the board 3 is flush. This method can directly weld the lead pin 2 to the lead board 3 above the lead board 3, and the solder joints will stay directly above the lead board 3 to ensure that the lower surface of the lead board 3 is flush. ;

[0041] S02. Assemble the lead pin 2 and the lead plate 3 into the lead frame 1, the lead plate 3 is in contact with the lower surface of the protruding ring 11, the lead pin 2 passes through the through hole on the protruding ring 11 on the inner wall of the lead frame 1, and The hole is filled with an insulating layer 13 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com