Solid insulating ring main unit

A technology of solid insulation and ring network cabinets, which is applied in the field of switch cabinets, can solve the problems of difficult recycling of solid-sealed pole shells, affecting the use of insulating ring network cabinets, and irreversible insulation performance, and achieves light weight, reduced weight, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

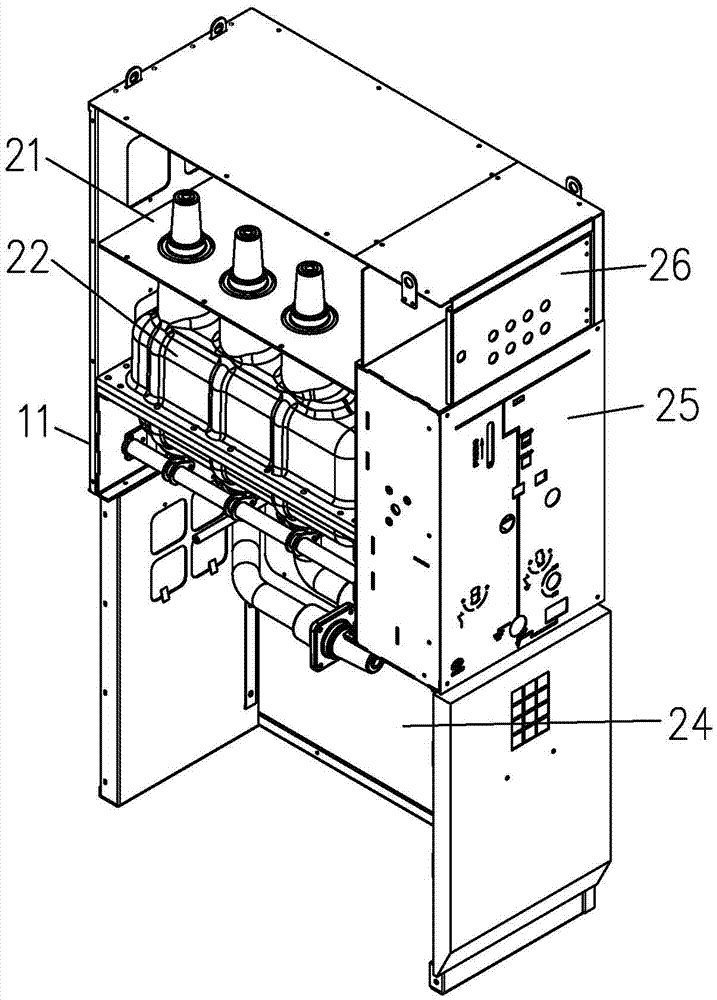

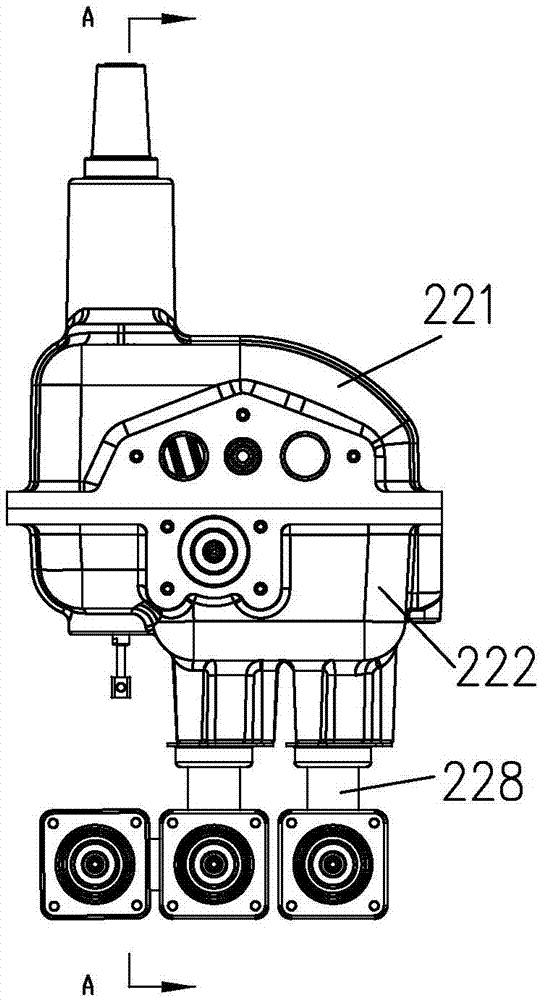

[0013] Such as figure 1 , 2 As shown, the solid insulated ring network cabinet of the present invention includes a housing 11 and a busbar chamber 21 disposed in the housing 11, a solid-sealed pole body 22, a cable chamber 24, a mechanism chamber 25, and a control chamber 26. The housing 11 is provided with There is a cabinet door, and the solid-sealed pole body 22 includes an upper pole shell 221 and a lower pole shell 222, both of which are made of glass fiber reinforced nylon resin.

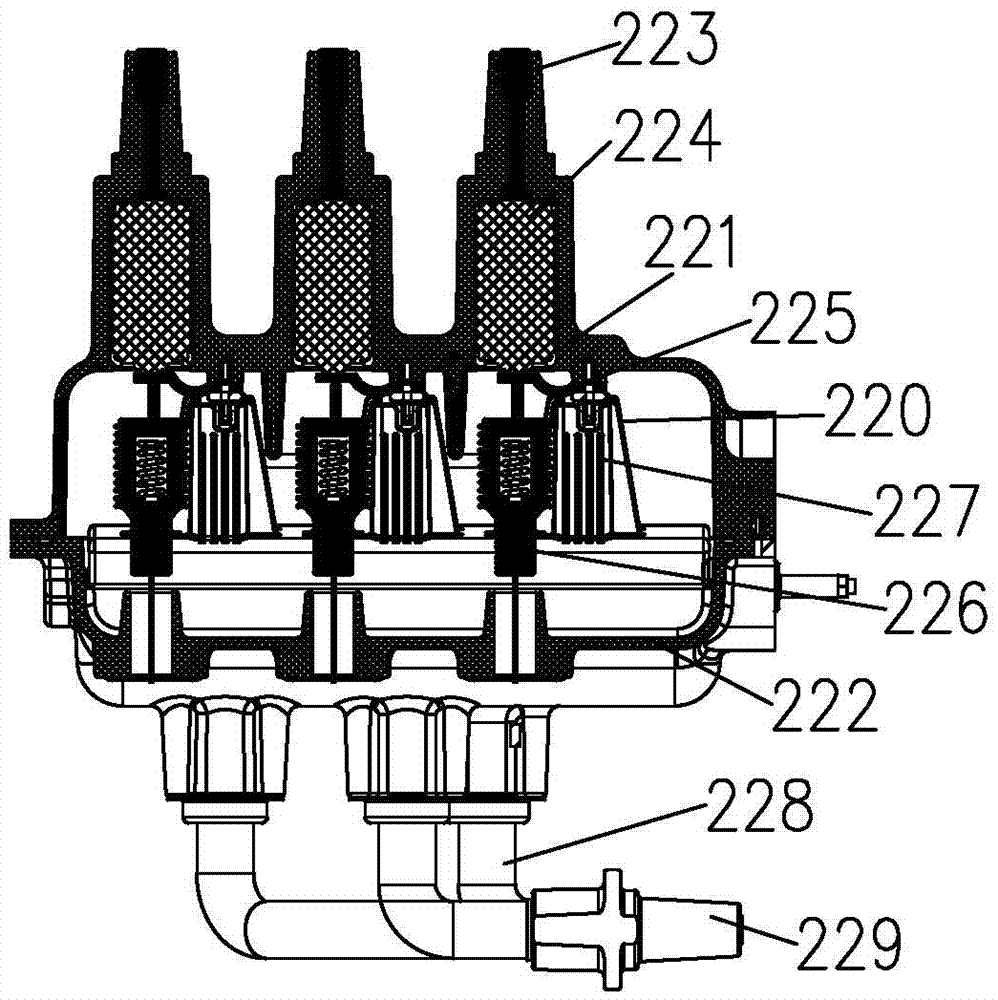

[0014] Such as image 3 As shown, the solid-sealed pole body 22 also includes an incoming line conductor 223, a vacuum interrupter 224, an outgoing line conductor (not shown in the figure), a soft connection 225, a circuit breaker pull rod 226, an isolation main shaft 227, an outgoing line bus bar 228 and an outgoing line conductor. Sleeve 229, pole upper shell 221, and pole lower shell 222 are all cast from glass fiber reinforced nylon resin. During the casting process of pole upper shell 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com