Water-cooled radiator, fabrication method thereof and cooling device with radiator

A manufacturing method and radiator technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of assembly accuracy relying on manual operation, complex shape, and reduced production capacity, and achieve continuity and stability of heat conduction performance, internal corrosion resistance Improvement, heat dissipation surface area optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

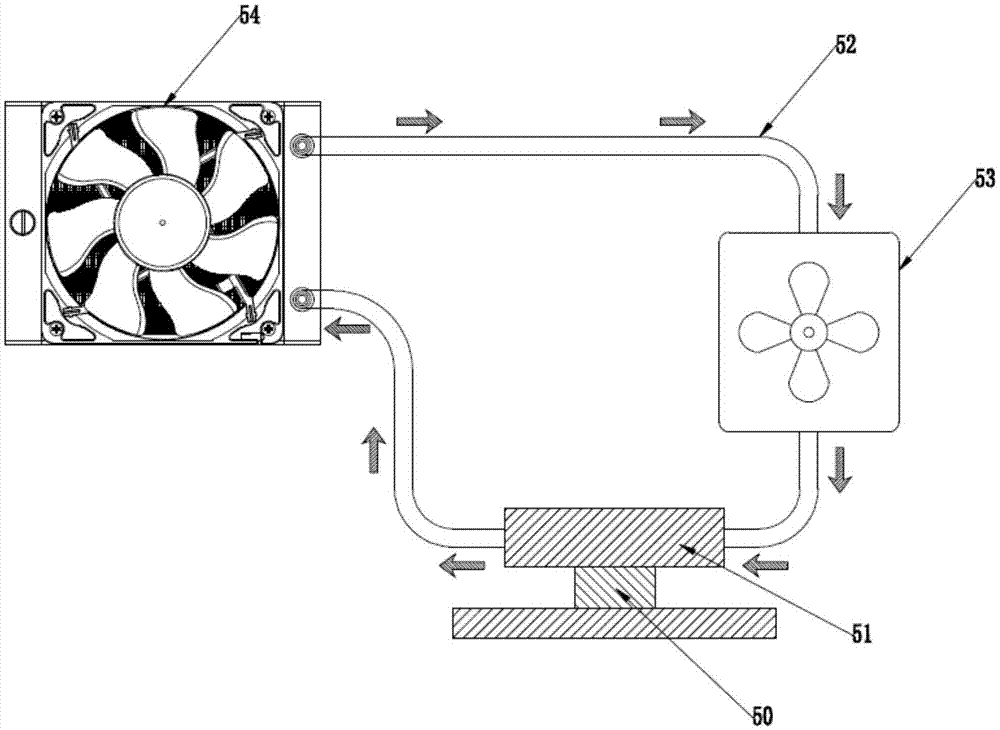

[0041] See water cooling systems such as figure 1 , including: heat source (Heatsource) 50, water cooling head 51 (collector Waterblock), circulation pipe 52 (pipe), water pump 53 (Pump), working liquid water, air-cooled radiator 54 (Radiator).

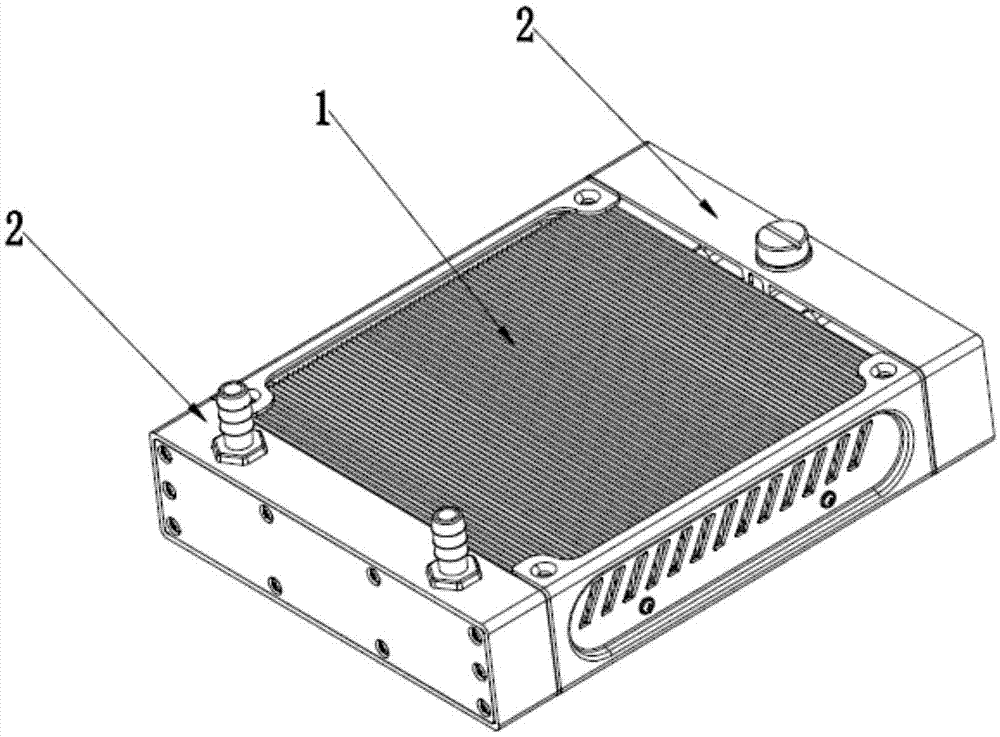

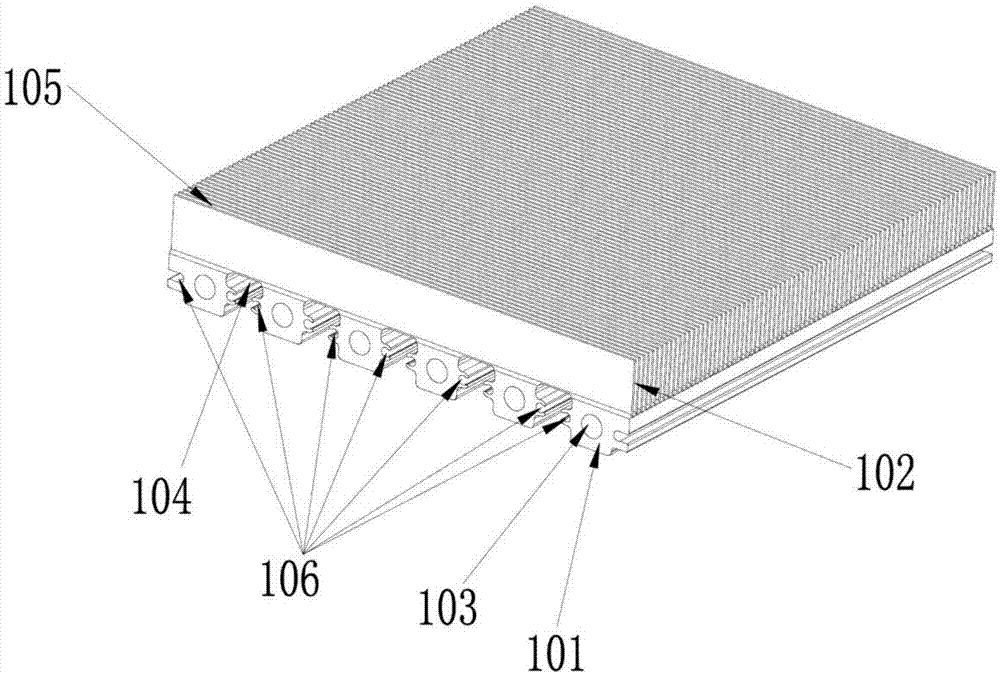

[0042] The radiator provided by this embodiment is as figure 2 , image 3 , Figure 4 ,include:

[0043] Heat sink 1, the heat sink 1 includes a metal body 101 with a plurality of grooves and a plurality of heat dissipation fins 102 above the metal body 101, the metal body 101 is provided with water cooling channels 103 running through its two ends, the metal body The gap between the groove of 101 and the heat dissipation fins 102 is directly connected to form a first heat dissipation air channel 104, and a second heat dissipation air channel 105 is separated between two adjacent heat dissipation fins 102. A heat dissipation air duct 104 and a second heat dissipation air duct 105 communicate with each other, and the bottom ends o...

Embodiment 2

[0061] Figure 10 , Figure 11 as well as Figure 12 A second embodiment of the present invention is illustrated. This example and Figure 2~4 The difference of the first embodiment shown in is that the water tank is made of metal, and the bottom end cover 203 and the top end cover 205 of the water chamber and the second sealing gasket 204 are combined by riveting process, so that the water chamber forms a water chamber sealed from the outside world The cavity 201, and the partition wall that controls the flow direction of water in the cooling body and the partition series and parallel combination also adopts the metal partition sheet 208. The purpose of using a metal water tank is to adapt to the application environment with different temperature and mechanical strength requirements, and its basic structure and principle are the same.

[0062] The water tank 2 includes a first sealing gasket 202 , a water chamber bottom end cover 203 , a second sealing gasket 204 and a wa...

Embodiment 3

[0064] Figure 13 and Figure 14 The third embodiment of the present invention is illustrated in conjunction with the schematic diagram of the manufacturing process. This example and Figure 2~4 The difference of the first embodiment shown in is that the heat dissipation area of the heat sink is further expanded, and the heat sink 1 includes a metal body 101 with more than one groove, and a plurality of heat dissipation fins 102 arranged above the body, in order to further expand The heat dissipation area is also provided with heat dissipation fins 102 below the metal body 101, and the bottoms of the upper and lower heat dissipation fins 102 are naturally connected to the metal body 101 as an overall structure; the metal body 101 on both sides of the groove is provided with The water-cooling channels 103 formed by the circular or special-shaped holes running through both ends can be used for liquid circulation, and the metal body 101 with through holes and the liquid insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com