Multi-segment temperature soldering packaging device and method for miniature solid laser

A technology for encapsulating devices and fixing lasers, applied in electric heating devices, welding equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, poor stability, low power, etc., to achieve short cycle times, simple and easy operation, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

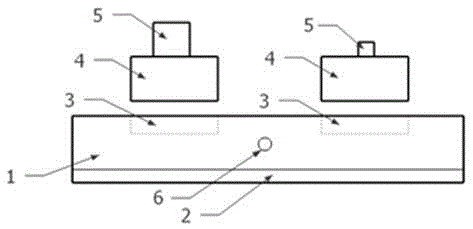

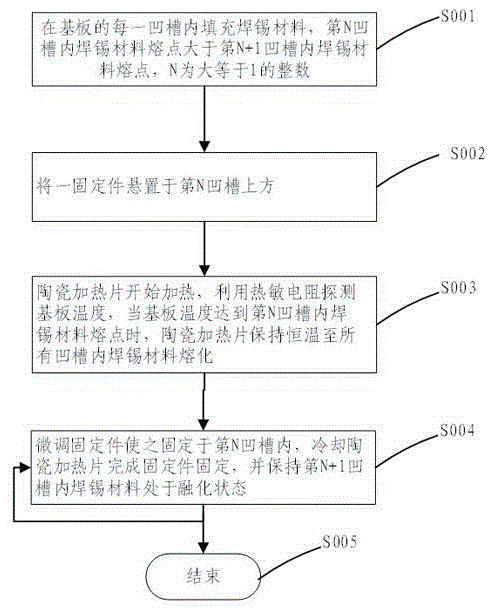

[0026] refer to figure 1 The multi-stage temperature welding packaging device of a miniature solid-state laser shown includes a substrate 1, a ceramic heating plate 2, and a fixing member; the fixing member includes an optical element 5 and a bracket 4, and the optical element 5 is fixed on the bracket 4 ; The ceramic heating plate 2 is close to the lower surface of the substrate 1; the substrate 1 is fixed on the operating platform with cooling function and high temperature resistance, the substrate 1 is provided with at least one groove 3, and each groove 3 is filled with Solder materials with different melting points, the bracket 4 on which the optical element 5 is fixed is fixed in the groove 3 through the solder material; the side wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com