Special welding gun for wire slot grounding stud

A technology of studs and welding torches, which is applied to the characteristics of welding rods, welding equipment, arc welding equipment, etc. It can solve the problems that the torch body is too long and cannot complete the welding operation of the wire slot grounding stud, so as to reduce the size of the torch head and compact structure ,Easy to operate and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

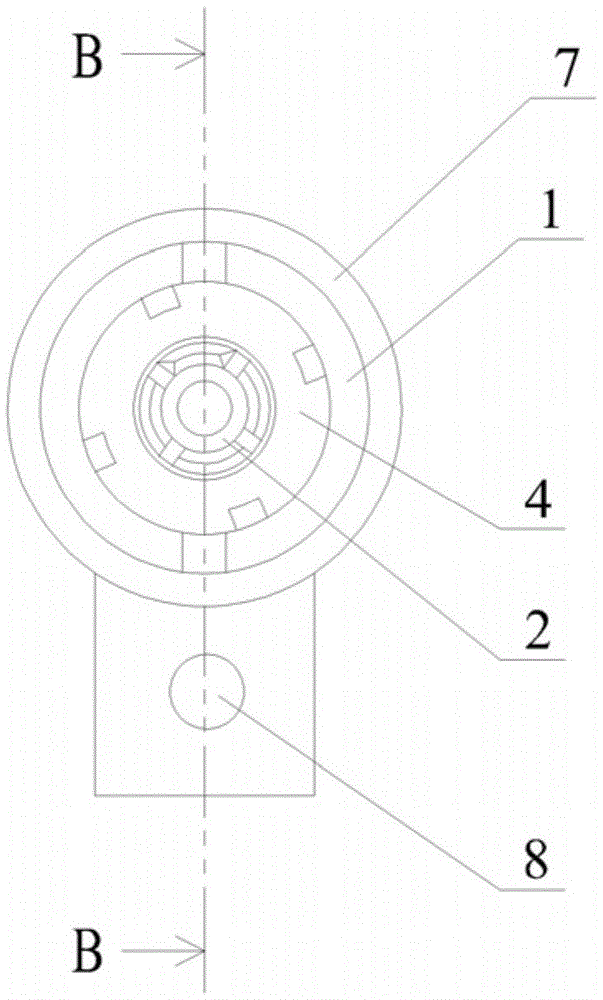

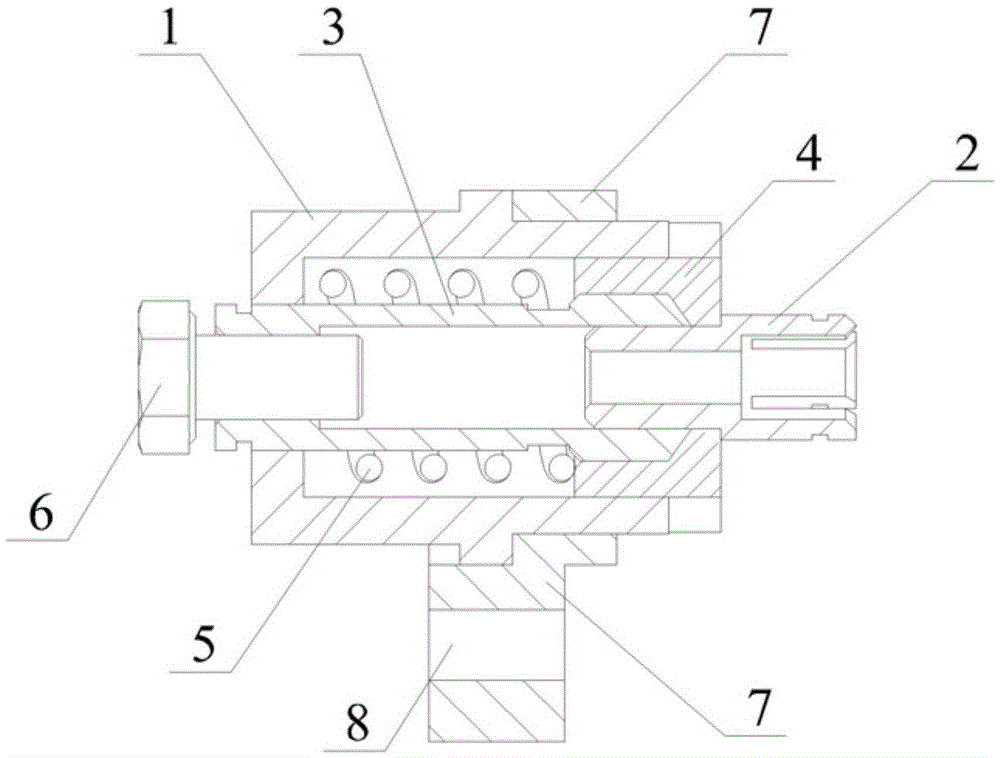

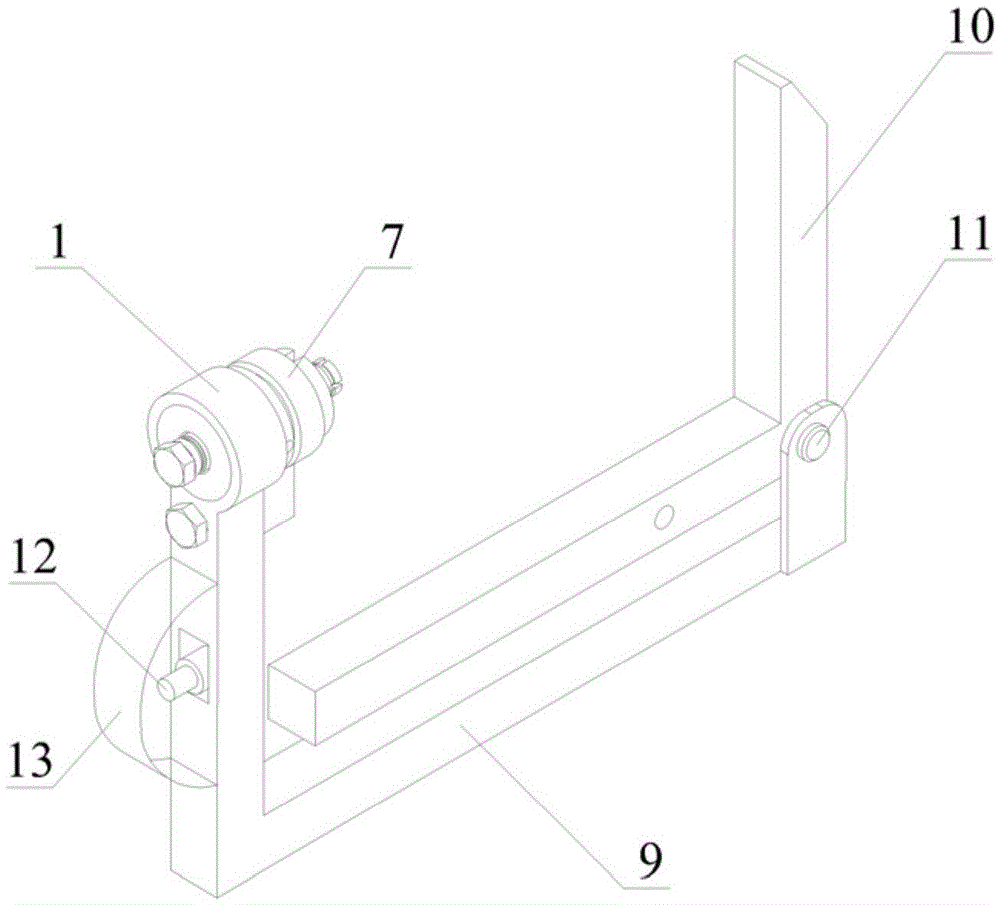

[0017] see figure 1 and figure 2 , The tip structure of the preferred embodiment of the present invention includes a conductive tip 2 , an insulating sleeve 1 and a guide rod 3 . The guide rod 3 is coaxially arranged in the insulating sleeve 1 , and the contact tip 2 is installed at one end of the guide rod 3 . The insulating bushing 1 undertakes the functions of positioning, guiding and arc extinguishing, replaces the functions of the three positioning claws, the guide ring and the insulating sleeve of the common torch head, and simultaneously increases the function of arc extinguishing. The torch head of this embodiment has the characteristics of compact structure and small size, and is suitable for welding grounding studs in wire slots with narrow spaces.

[0018] In order to further reduce the size of the gun head, in this embodiment, the end of the guide rod 3 where the conductive tip is installed is set as a hollow tube, the conductive tip 2 is installed inside the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com