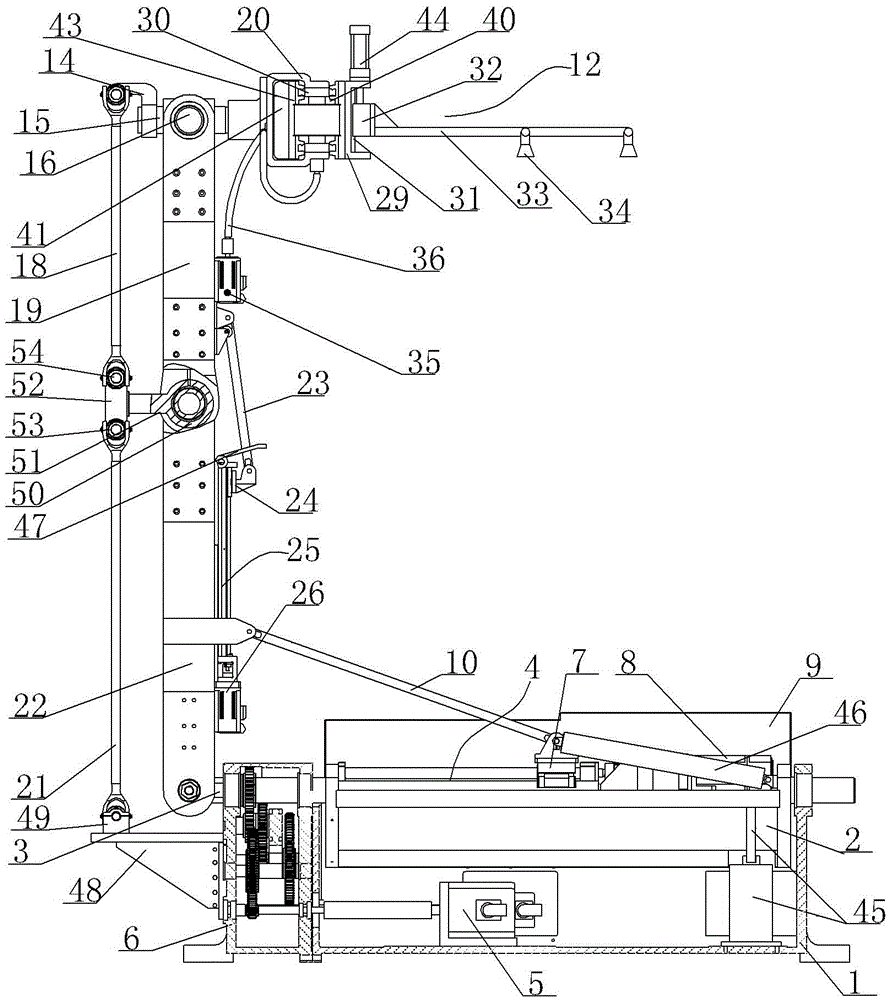

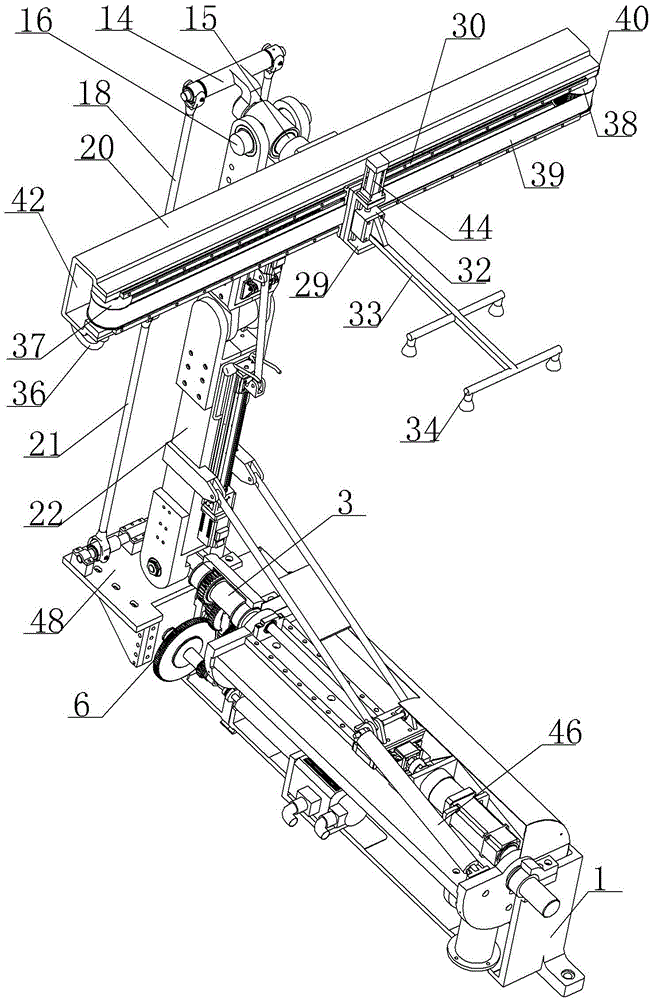

Seven-axis five-power robot applying parallelogram principle

A parallelogram and robot technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of narrow control range, affecting the control accuracy of manipulators, and easy shaking of manipulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0046] The first shaft reducer 6 in the specific embodiment 2 is specifically a gear box;

[0047] In the second specific embodiment, the terminal gripper 34 is driven by the flexible shaft servo motor 35 and can move 1500 mm in the horizontal direction, and can move vertically by 100 mm in the vertical direction through the drive of the vertical cylinder 44, which makes the working range of the terminal gripper 34 of the entire robot Larger and more suitable for modern work;

[0048] Can install dustproof cover 9 additionally on the base, be used for dustproof.

[0049] The seven-axis robot includes five powers: the first axis servo motor 5, the second axis working module 4, the third axis working module 25, the flexible axis servo motor 35, and the vertical cylinder 44, which greatly improves the flexibility of the gripper and operational range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com