Multifunctional waterproof and air-permeable composite

A waterproof, breathable and composite material technology, applied in electronic equipment, synthetic resin layered products, applications, etc., can solve the problems of affecting the quality of sound transmission, affecting the life of equipment, damaging products, etc., to prevent water and dust from entering the interior of electronic products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

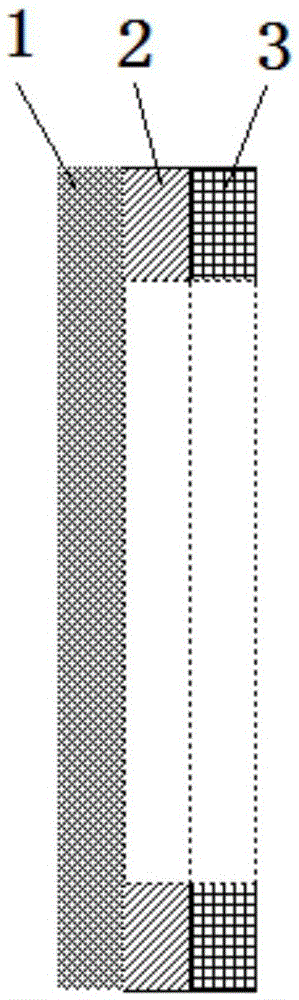

[0029] Such as figure 1 As shown, the present invention includes a waterproof breathable membrane 1, an adhesive layer A2 and a protective layer A3 arranged in sequence, and the waterproof breathable membrane 1 and the protective layer A3 are adhered together by the adhesive layer A2, and the protective layer A3 A hole is arranged on the top, and only the waterproof and breathable membrane 1 is covered at the hole.

[0030] When in use, peel off the protective layer A3 of this product corresponding to the size specification of the corresponding electronic product to be coated, and flush the waterproof and breathable membrane 1, so that the adhesive layer A2 and the electronic product to be coated are adhered together That's it.

[0031] Alternatively, the front of the waterproof and breathable membrane 1 is directly attached to the place where the electronic product is to be coated, and the protective layer A3 is always on the outermost side as the protective layer.

Embodiment 2

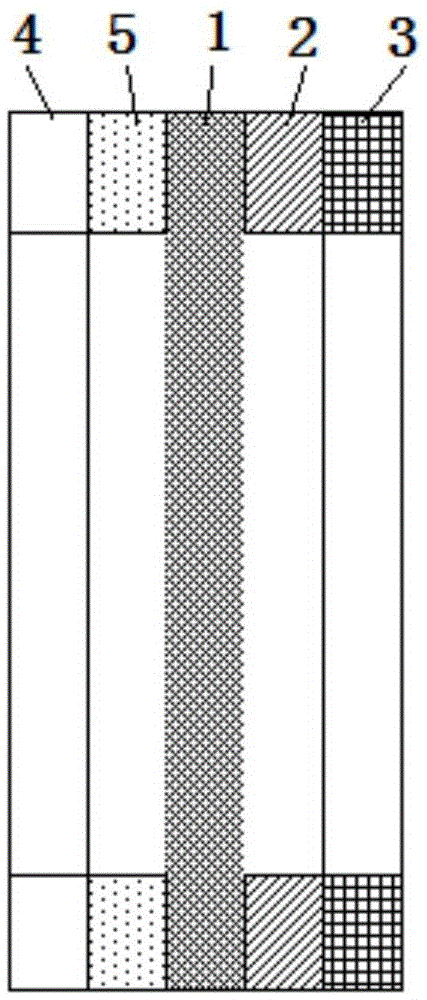

[0033] Such as figure 2 As shown, on the basis of Example 1, a support layer 4 is also included, and the support layer 4 is connected to the waterproof and breathable membrane 1 through the adhesive layer B5, and the support layer 4 and the adhesive layer B5 are also provided with corresponding holes.

[0034] When in use, peel off the protective layer A3 of this product corresponding to the size specification of the corresponding electronic product to be coated, so that the adhesive layer A2 and the electronic product to be coated can be adhered together.

Embodiment 3

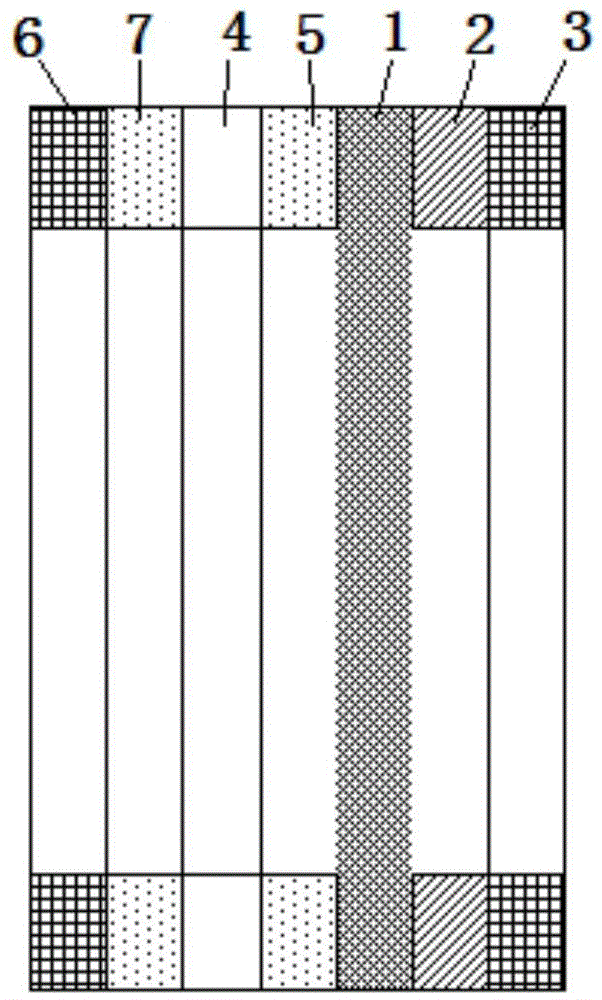

[0036] Such as image 3 As shown, on the basis of Example 2, a protective layer B6 is also included, and the protective layer B6 is connected to the support layer 4 through the adhesive layer C7, and the protective layer B6 and the adhesive layer C7 are also provided with corresponding holes.

[0037] When in use, peel off the protective layer A3 of this product corresponding to the size specification of the corresponding electronic product to be coated, so that the adhesive layer A2 and the electronic product to be coated can be adhered together;

[0038] Alternatively, the protective layer B6 can be peeled off, so that the adhesive layer C7 and the electronic product to be coated can be adhered together.

[0039] In the above embodiment, the waterproof and breathable membrane 1 is a TPU puffed film or a polytetrafluoroethylene puffed film with a thickness of (0.01-0.5)±0.005mm; the adhesive layer A2 is made of waterproof foam glue or double Surface glue; the protective lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com