Oil-electric hybrid power multi-rotor aircraft

A technology of multi-rotor aircraft and hybrid electric power, applied in aircraft, rotorcraft, motor vehicles, etc., can solve the problems of limited flight time, small load, short range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0097]DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

example 1

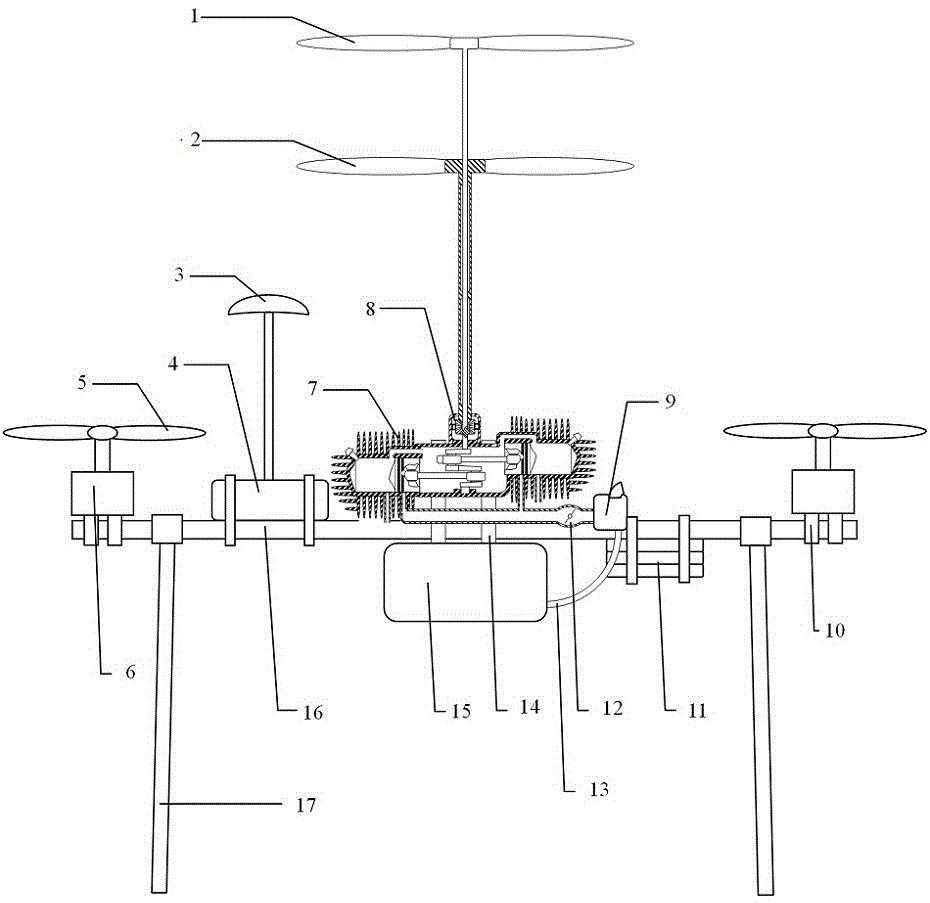

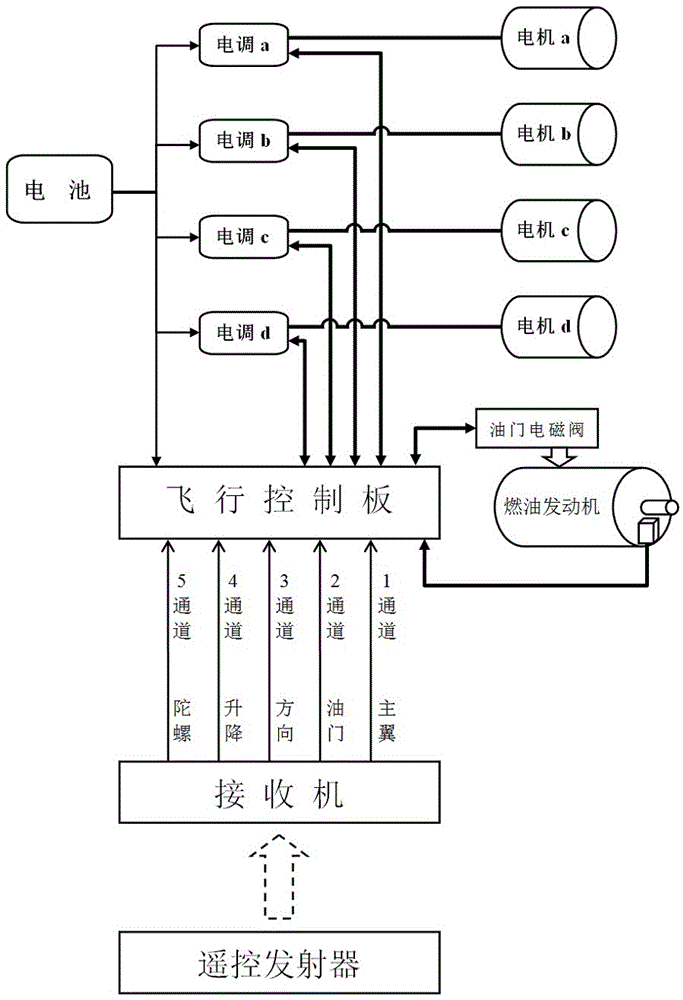

[0098] Example 1: The fuel-electric hybrid aircraft is divided into the main rotor and the auxiliary rotor to provide flight power. The main rotor provides the main lift-off power, and the auxiliary rotor provides a small part of the lift-off power. The main rotor consists of the upper main rotor 1 and the lower main rotor 2. (see figure 1 shown), the upper main rotor shaft 18 passes through the lower main rotor sleeve shaft 19 of the lower main rotor 2 from the top and is welded with the lower bevel gear 21 and then fixed with the power output shaft of the engine. The main shaft of the lower main rotor 2 is the lower The main rotor sleeve shaft 19 has a cavity inside the sleeve shaft, and only the upper, middle and lower end surfaces are in contact with the inner upper main rotor shaft 18 to form constraints, so that the lower main rotor sleeve shaft 19 and the upper main rotor shaft 18 It can rotate independently of each other along the same axis. The lower main rotor sleeve...

example 2

[0099] Example 2: The fuel-electric hybrid aircraft is divided into the main rotor and the auxiliary rotor to provide flight power. The main rotor provides the main lift-off power, and the auxiliary rotor provides a small part of the lift-off power. The main rotor consists of the upper main rotor 1 and the lower main rotor 2. (see figure 1 shown), the upper main rotor shaft 18 passes through the lower main rotor sleeve shaft 19 of the lower main rotor 2 from the top and is welded with the lower bevel gear 21 and then fixed with the power output shaft of the engine. The main shaft of the lower main rotor 2 is the lower The main rotor sleeve shaft 19 has a cavity inside the sleeve shaft, and only the upper, middle and lower end surfaces are in contact with the inner upper main rotor shaft 18 to form constraints, so that the lower main rotor sleeve shaft 19 and the upper main rotor shaft 18 It can rotate independently of each other along the same axis. The lower main rotor sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com