Coating structure with flame retardant and thermal insulation functions

A technology of flame retardant heat preservation and coating, which is applied in the field of coating structure with flame retardant heat preservation function, can solve the problems of flammability, easy fire, aging resistance, etc., and achieve low raw material cost, good coating adhesion, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

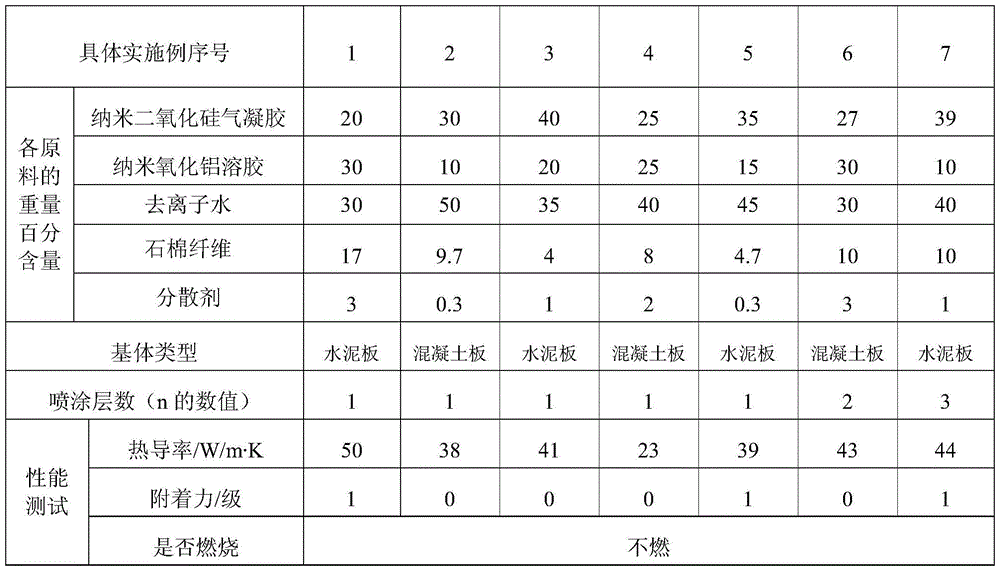

Examples

Embodiment Construction

[0018] The present invention is further described below by example.

[0019] In each embodiment of the present invention, the nano-alumina sol is selected from the product produced by Hefei Xiangzheng Chemical Technology Co., Ltd. with a mass concentration of 10-30%, and the particle size is 70-100nm; Esters (analytical pure, Sinopharm Chemical Reagent Co., Ltd.) and ethanol (analytical pure, Sinopharm Chemical Reagent Co., Ltd.), hydrochloric acid (analytical pure, Sinopharm Chemical Reagent Co., Ltd.) were prepared by hydrolysis and polycondensation at 70°C. The density is 100kg / m 3 , the preparation method belongs to the prior art, and will not be repeated in the present invention. The asbestos fiber is selected from Shandong Zhengjue Industrial Co., Ltd., with a diameter of 1-5um and an aspect ratio of 5-10; the dispersant is polyethylene glycol 6000, an analytically pure product produced by Sinopharm Chemical Reagent Co., Ltd.

[0020] The flame-retardant thermal insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com