Flame-retardant ABS composition and preparation method thereof

A technology of composition and flame retardant, applied in the field of flame retardant ABS composition, can solve the problems affecting the tensile strength of materials, etc., and achieve the effect of solving material appearance defects, excellent thermal stability, flame retardant performance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

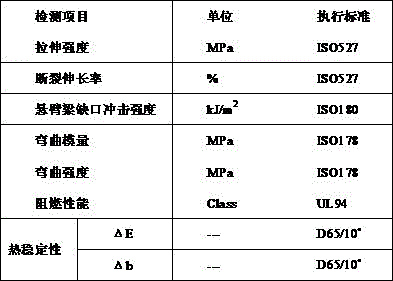

Examples

Embodiment 1-12 and comparative example 1-8

[0066] Examples 1-12 and Comparative Examples 1-8: Preparation of Flame Retardant ABS Composition

[0067] Sulfur-containing compounds, phosphorus-containing compounds and silicone oil are formulated into a silicone oil solution with a mass fraction of 25ppm-2500ppm; tin-containing compounds and silicone oil are formulated into a silicone oil solution with a mass fraction of 20ppm-3500ppm; the two silicone oil solutions obtained above are mixed with the ABS, flame retardant, and processing aid are uniformly mixed in a high-speed mixing mixer according to the ratio in Table 1 to obtain a premix; the above premix is sent into a twin-screw extruder, extruded, and cooled by water. The flame-retardant ABS composition is obtained by granulation; wherein, the temperature of each section of the screw of the twin-screw extruder from the feed port to the machine head is preferably 80°C in the first zone, 160°C in the second zone, and 180°C in the third zone. The temperature of the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com