γ-Cyclodextrin and Ruthenium Complexes and Their Applications in Microcontact Printing Technology

A technology of microcontact printing and ruthenium complexes, which is applied in the field of modern electronics, can solve the problems that have not been reported in the application, and achieve the effects of high cell survival rate, easy availability of raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Substrate surface treatment: Soak polyethylene in 45% isopropanol aqueous solution for 30 minutes, wherein the mass percentage of isopropanol solution and polyethylene is 1:1, take it out and put it in 2mol / L sulfuric acid solution immersion at a temperature of 55°C for 15 minutes, then washed with water, and vacuum-dried at a temperature of 60°C to introduce carboxyl groups on the surface of the polymer substrate to obtain a carboxylated polyethylene substrate;

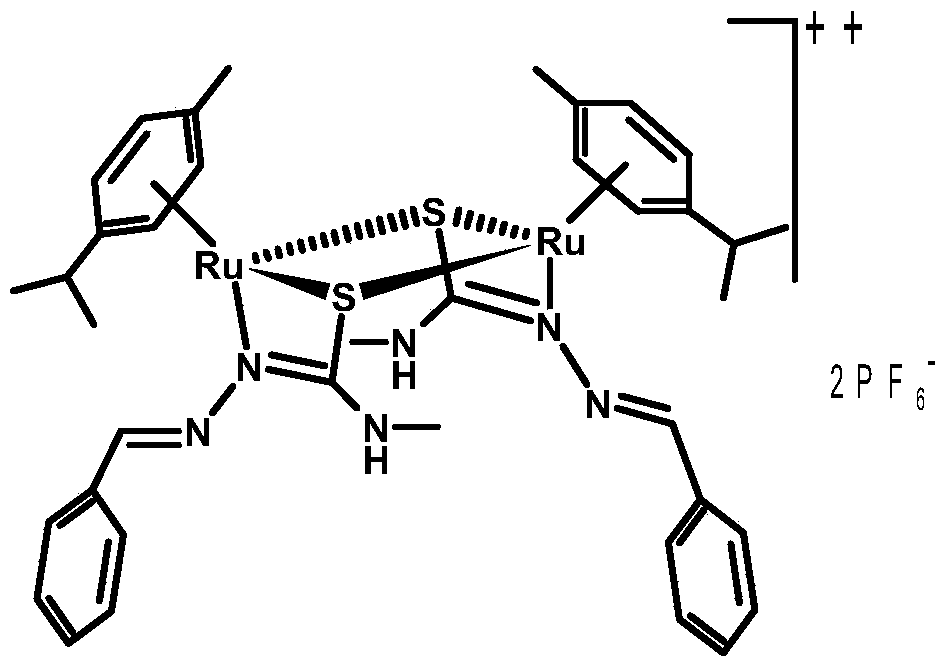

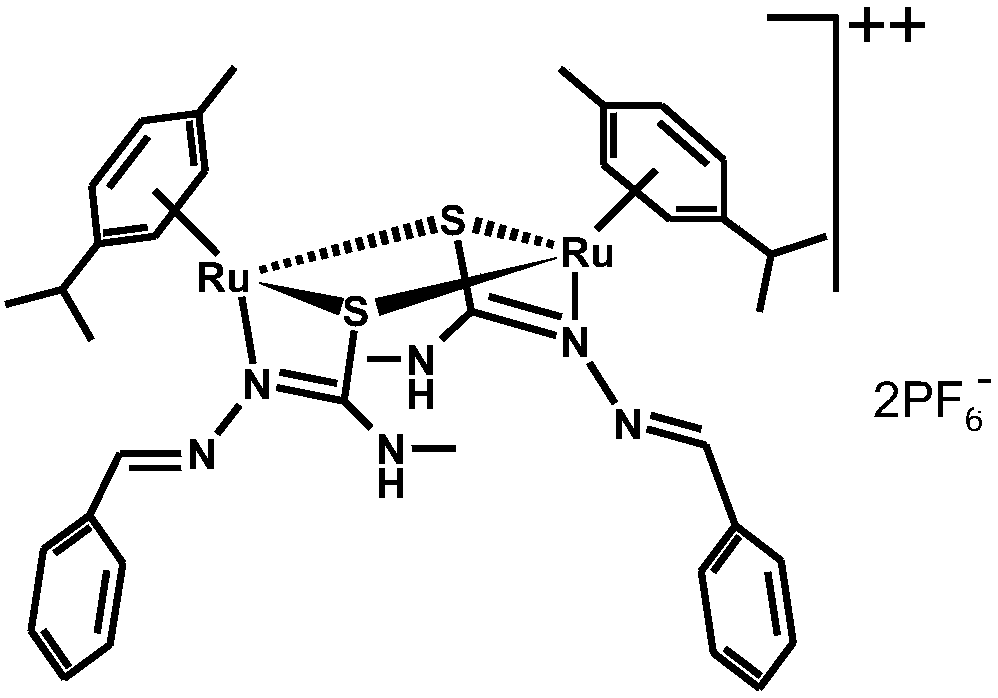

[0030] 2) Prepare the composite solution of γ-cyclodextrin and ruthenium complex: dissolve γ-cyclodextrin in water to obtain an aqueous solution of γ-cyclodextrin with a concentration of 3 g / L, and add 0.8 g ruthenium complex, and then use an ultrasonic instrument to adjust the frequency to 20kHz for 30 minutes to obtain a uniformly dispersed γ-cyclodextrin and ruthenium complex composite solution;

[0031] 3) Microcontact printing: Soak the PDMS stamp in the composite solution of γ-cyclodextrin and rutheni...

Embodiment 2

[0035] 1) Substrate surface treatment: Soak polyethylene in 55% isopropanol aqueous solution for 60 minutes, wherein the mass percentage of isopropanol solution and polyethylene is 1:5, take it out and put it in 3mol / L sulfuric acid solution , and soaked at a temperature of 65°C for 20 minutes, then washed with water, and vacuum-dried at a temperature of 65°C to introduce carboxyl groups on the surface of the polymer substrate to obtain a carboxylated polyethylene substrate;

[0036] 2) Preparation of γ-cyclodextrin and ruthenium complex solution: dissolve γ-cyclodextrin in water to obtain an aqueous solution of γ-cyclodextrin with a concentration of 6 g / L, and add 0.8 g ruthenium complex, and then use an ultrasonic instrument to adjust the frequency to 20kHz for 60 minutes to obtain a uniformly dispersed γ-cyclodextrin and ruthenium complex composite solution;

[0037] 3) Microcontact printing: Soak the PDMS stamp in the composite solution of γ-cyclodextrin and ruthenium comp...

Embodiment 3

[0041] Human normal epidermal cells HaCaT were cultured in Dulbecco's Modified Eagle's Medium (DMEM) medium (containing 10% newborn bovine serum) at 37°C and 5% CO 2 Cultivate under conditions, and change the culture medium once every 1-2 days. When the cells grow to the logarithmic phase, the metal pattern substrate obtained in Example 1 and Example 2 and the polyethylene substrate before carboxylation are added for treatment. Place the cells in a 96-well plate with 0.25% trypsin at 37°C, 5% CO 2 Incubator cultivation. After 2 to 4 hours, each culture plate was added with the metal pattern substrate obtained in Example 1 and Example 2, the polyethylene substrate before carboxylation and the cells cultured in complete culture medium as the experimental group and the control group, without cells and cultured solution as a blank control, the culture plate was moved to 37 ℃, 5% CO 2 Incubator cultivation. After 24 hours, discard the culture medium, wash the plate twice with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com