Self-propelled metal corrosion protection method and system

A metal corrosion and self-driven technology, applied in the field of metal corrosion protection, can solve the problems of replacing sacrificial anodes, cathodic protection can not be separated from external power supply, etc., achieves simple preparation process, is conducive to large-scale industrial production and practical application, and overcomes technical costs higher effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

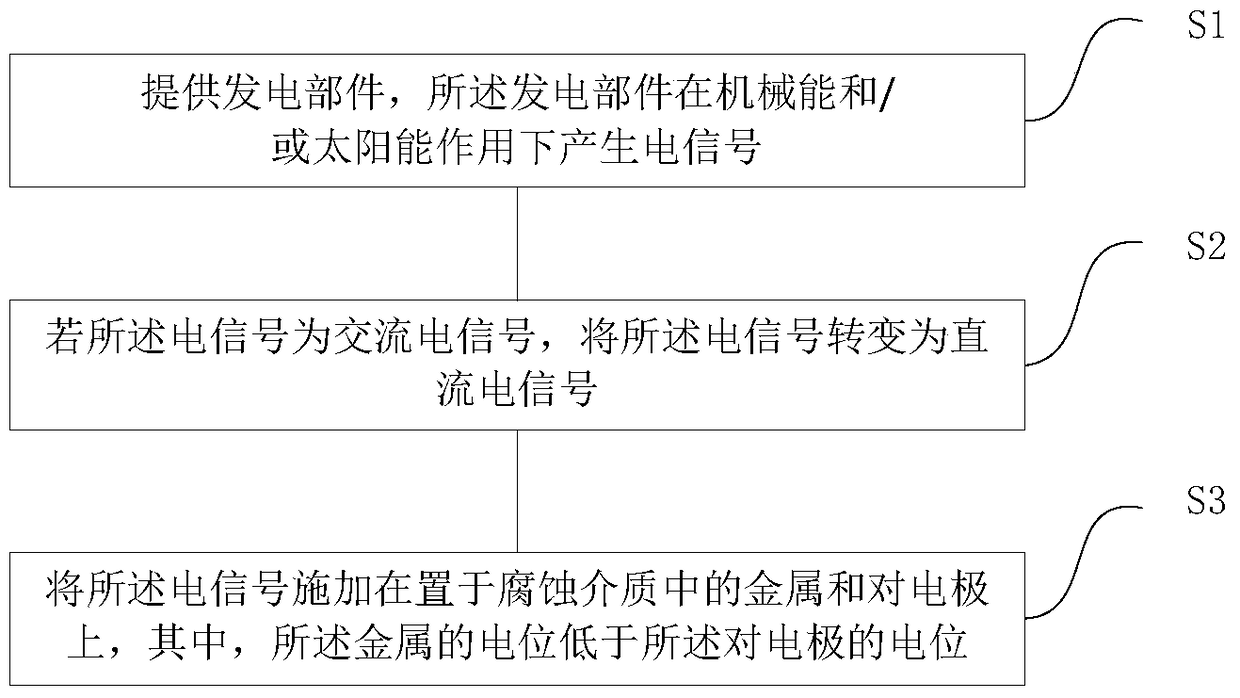

[0061] For the self-driven metal corrosion protection method involved in this embodiment, see the flow chart figure 1 ,include:

[0062] Step S1, providing a power generating component, which generates an electrical signal under the action of mechanical energy and / or solar energy.

[0063] In the metal corrosion protection method of this embodiment, power generation components can be used to convert mechanical energy such as wind energy, tides, sea waves, etc. or solar energy that are ubiquitous in the environment into electrical energy.

[0064] The power generation component in the present invention may include a friction generator utilizing friction power generation and electrostatic inductive coupling. Typical friction generators are of sliding friction type and contact separation type. Here, the sliding friction generator is taken as an example to illustrate the application of friction generators in metal corrosion protection.

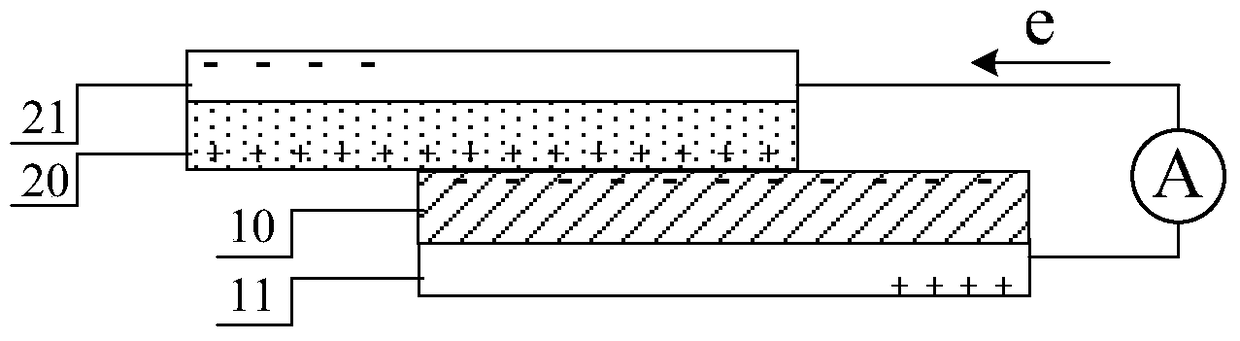

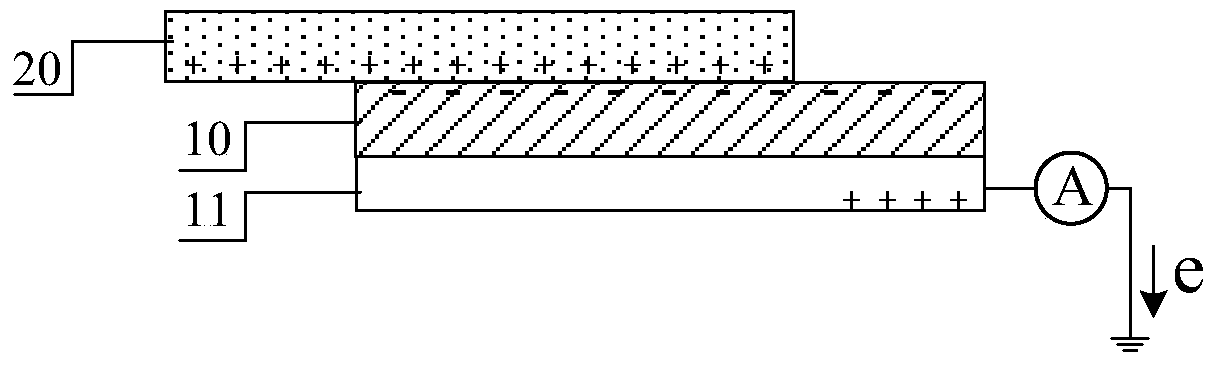

[0065] For a typical structure of a frict...

Embodiment 2

[0086] In this embodiment, a rotary friction generator is provided to illustrate the influence of the output power of the friction generator on the metal corrosion protection potential.

[0087] Figure 5 The a-c in the present embodiment is the structural diagram of the rotary friction generator, including two mutually rotating parts, both parts are the turntable structure of the same periodic sector, and the two parts are the same periodic sector Turntable structure, each part is formed by lamination of friction material layer and electrode material layer. When the two parts rotate around the rotation center, the two friction materials can change between completely overlapped and completely separated. There is an alternating current signal output on the electrode of the contact setting. Such as Figure 5 In a and b, the so-called "periodic sector" refers to a plurality of fan-shaped areas with the same size and equal intervals distributed around the rotation center on the ...

Embodiment 3

[0100] This embodiment provides a method for changing the cathodic polarization potential of the corrosion system by changing the internal resistance of the corrosion medium, thereby achieving the purpose of improving metal corrosion protection.

[0101] Step S3 applies the electric signal to the metal and the counter electrode placed in the corrosive medium, specifically: placing the metal and the counter electrode in two separate corrosive media, wherein the two The corrosive medium is the same, and the two corrosive mediums are connected by a capillary filled with corrosive medium. The length of the capillary is more than 0.5m, preferably 0.5m-2m, and the diameter of the capillary is in the range of 0.3mm-1mm.

[0102] Still taking the corrosion protection of 403 stainless steel as an example, the metal corrosion protection method of this embodiment is described. In order to further increase the absolute value of the polarization potential of 403 stainless steel, the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com