An intelligent cement-soil mixing pile adding and feeding operation method for pile formation

A technology of cement-soil mixing piles and operating methods, which is applied in the direction of conveying bulk materials, conveyors, sheet pile walls, etc., can solve problems affecting social stability, high labor costs, complex structures, etc., and achieve thorough guarantee of construction quality and save cement The effect of simple materials and structural forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

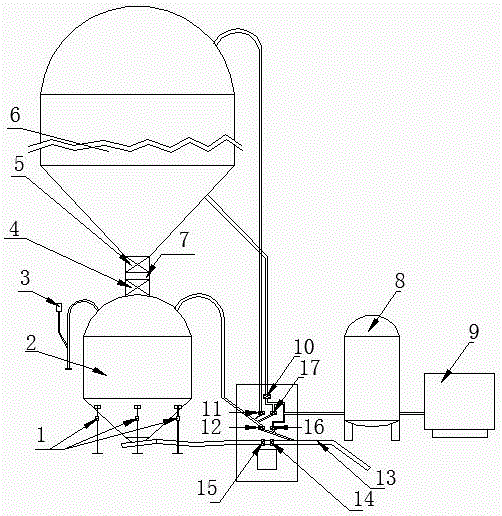

[0017] An intelligent cement-soil mixing pile adding and feeding operation method to form a pile,

[0018] It includes an intelligent material conveying system, a main ash conveying pipe connected to the pile driver, and a high-pressure gas supply system. The intelligent conveying system includes a collection tank and a material conveying tank;

[0019] When drilling, the cement is first quantitatively fed from the collecting tank to the conveying tank, and the high-pressure air provided by the high-pressure gas supply system increases the pressure in the conveying tank to 0.5-0.8MPa, and then starts intermittently conveying cement to the ash conveying main pipe. And through the high-pressure air provided by the high-pressure gas supply system, the cement in the ash conveying main pipe is sent to the soil. The drill pipe of the pile driver is drilled every 10-20cm, and the material conveying tank is used to convey cement once for the ash conveying main pipe. The amount of ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com