Fuel pump

A fuel pump and fuel technology, applied in the direction of fuel injection pump, fuel injection device, special fuel injection device, etc., can solve problems such as piston corrosion and fuel pump no longer running.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

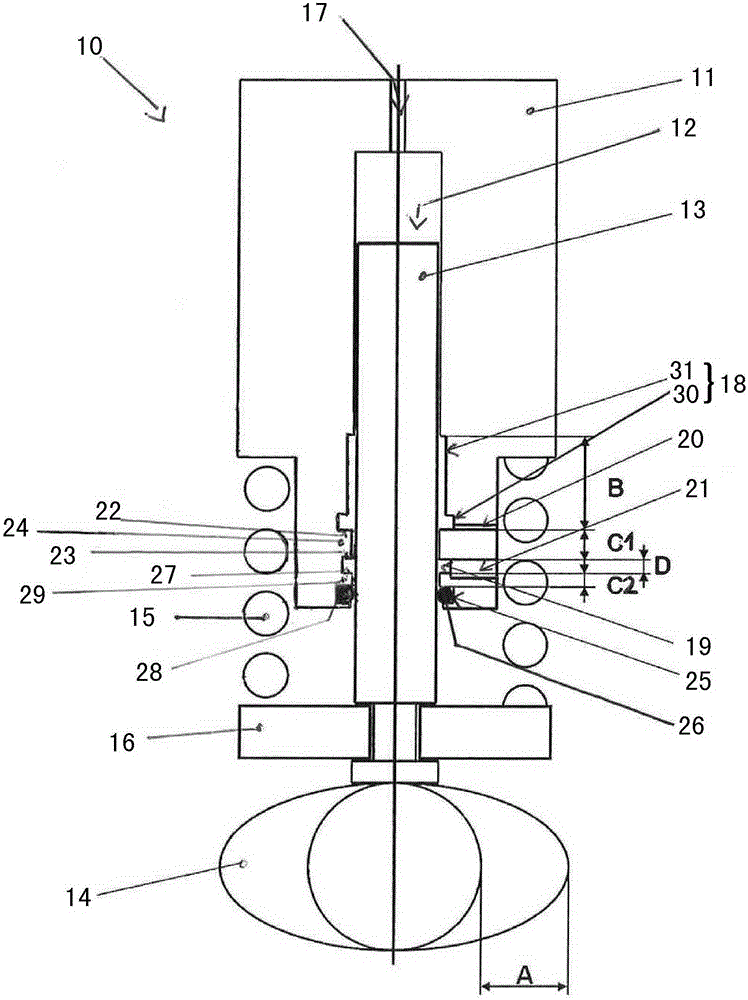

[0016] The invention here relates to a fuel pump, in particular a high-pressure fuel pump for a fuel common rail system of an internal combustion engine operated with heavy fuel oil, such as a marine diesel internal combustion engine.

[0017] figure 1 A cross section of a fuel pump 10 according to the invention is shown, wherein the fuel pump 10 has a pump cylinder 11 and a pump piston 13 movably mounted in a recess 12 of the pump cylinder 11 . The pump piston 13 can move up and down or reciprocate in the gap 12 of the pump cylinder 11 , that is, the movement is controlled by the cam 14 . The cam 14 is also called a driving cam. The movement of the pump piston 13 caused by the cam 14 is counteracted by a restoring force provided by a return spring 15 , also referred to as a drive spring. The drive spring 15 is supported on the one hand on the pump cylinder 11 and on the other hand on a bearing element 16 coupled to the pump piston 13 .

[0018] exist figure 1 The fuel pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com