Compressor and refrigerating cycle device thereof

A technology of a compressor and a compression mechanism, applied in the field of compressors, can solve the problems of reducing the working efficiency of the compressor, reducing the efficiency of the refrigeration cycle device, increasing the superheat degree of the refrigerant in the compression chamber, etc., so as to improve the cooling effect, improve the efficiency, and improve the compression. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

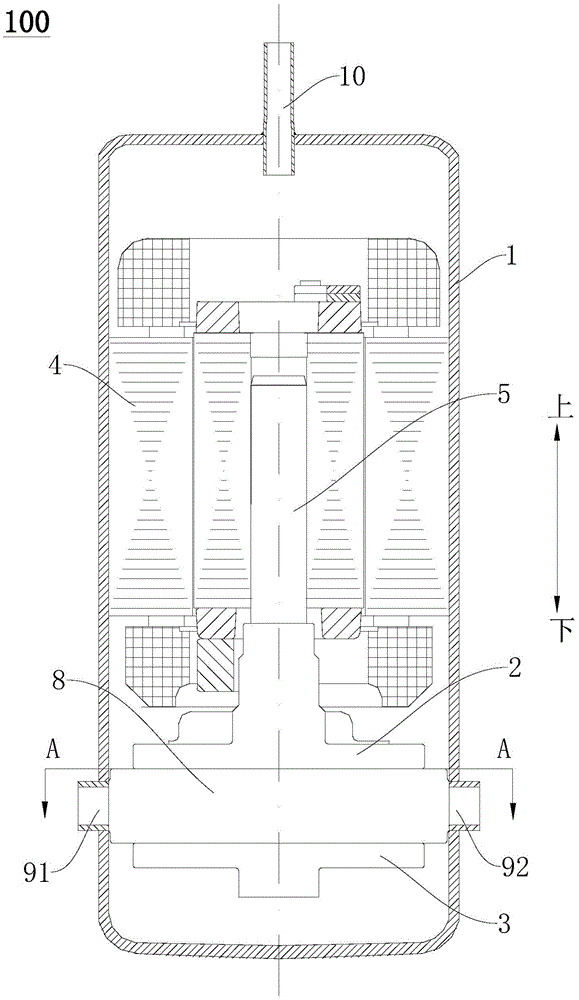

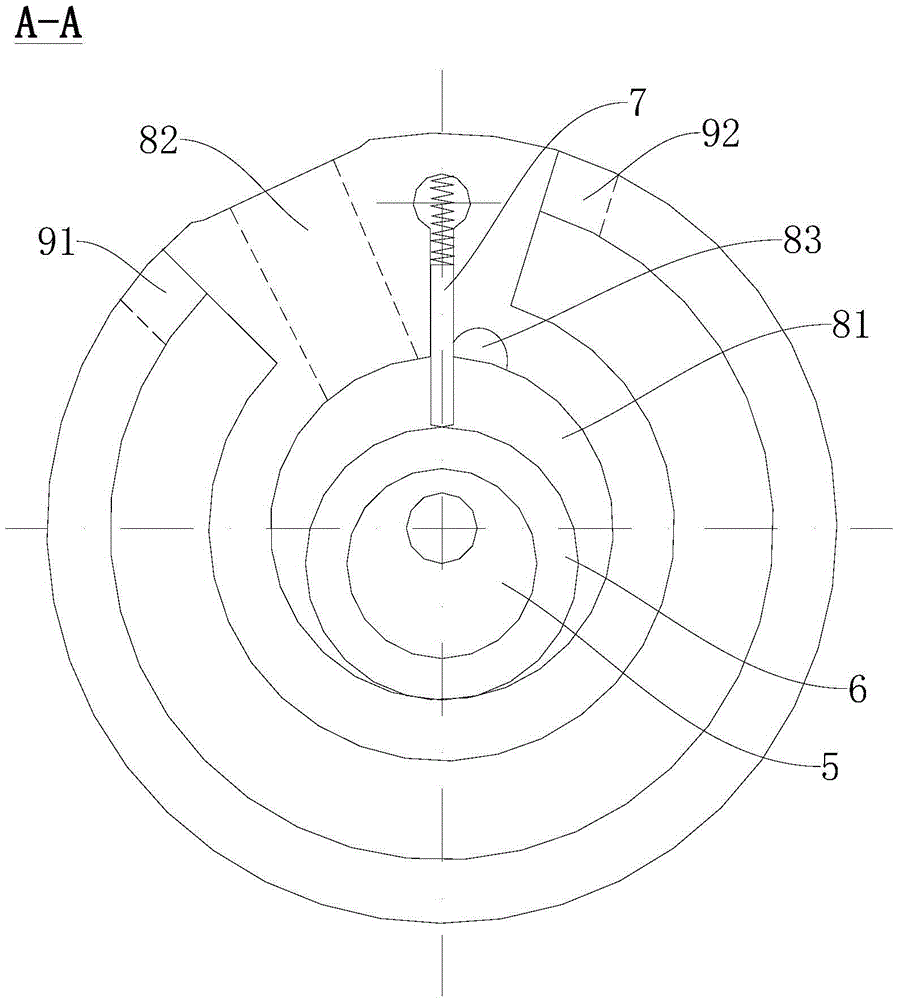

[0051] Such as Figure 1-Figure 4 As shown, in this embodiment, the cylinder assembly may include one cylinder 8 . The main bearing 2 is located at the upper end of the cylinder, and the auxiliary bearing 3 is located at the lower end of the cylinder. The cylinder 8 has a compression chamber 81 , and an air intake port 82 and an exhaust port 83 communicating with the compression chamber 81 are formed on the cylinder 8 .

[0052] The inlet 91 of the cooling chamber is located on the side where the air intake 82 is located, and the outlet 92 of the cooling chamber is located on the side where the exhaust port 83 is located. Because the height of the bottom surface of the cooling chamber at the inlet 91 is higher than the height at the outlet 92, that is, the height of the bottom surface of the cooling chamber on the side where the suction port 82 is located is higher than the height on the side where the exhaust port 83 is located, Since the temperature of the refrigerant at t...

Embodiment 2

[0070] Such as Figure 5 and Figure 6 As shown, the difference between the compressor 100 in this embodiment and the first embodiment above is only in the configuration of the cooling cavity. Other structures of the compressor 100 in this embodiment are substantially the same as those in the first embodiment above, and will not be repeated here.

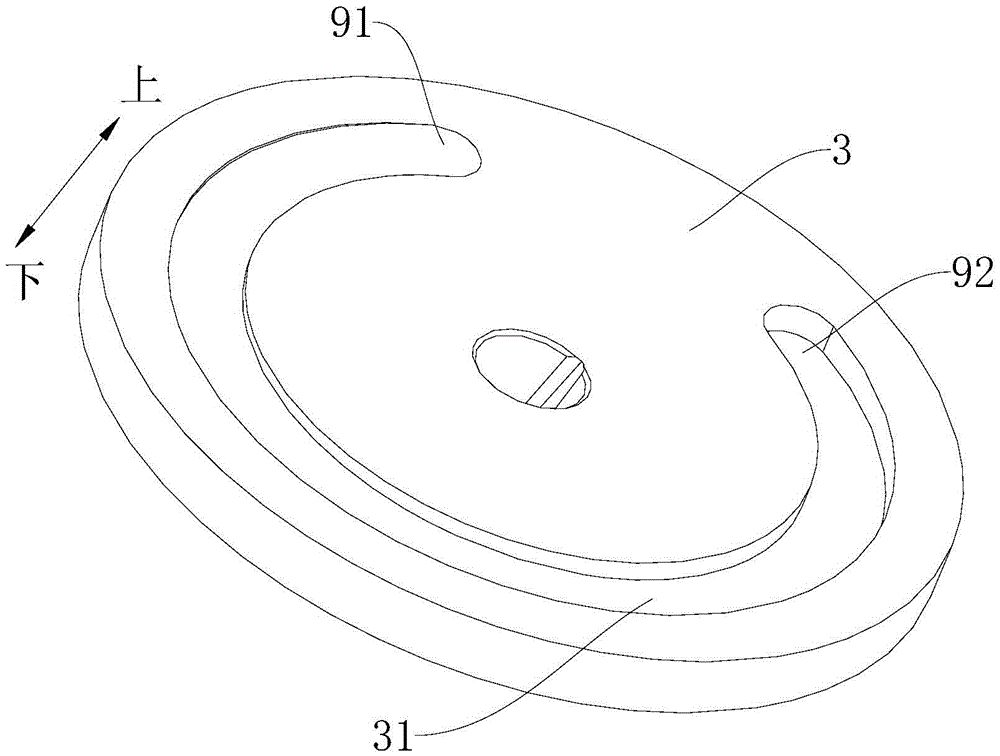

[0071] refer to Figure 5 and Figure 6 and combine figure 1 and figure 2 A second groove 32 is formed on at least one of the main bearing 2 , the cylinder assembly and the auxiliary bearing 3 . The second groove 32 is substantially the same as the first groove 31 in the first embodiment in terms of setting position and molding method, except that the bottom surface of the second groove 32 is a plane, and the bottom wall of the second groove 32 is flat. A bottom structure 33 is provided on it, and the bottom surface of the cooling chamber is the upper surface of the bottom structure 33 at this time. Thereby, the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com