A device and method for keeping evaporator working without frost

A technology of evaporators and evaporative heat exchangers, which is applied to household refrigeration equipment, defrosting, lighting and heating equipment, etc. It can solve the problems of increased system complexity, high energy consumption in the defrosting process, and expensive equipment, and achieves applicable Wide range, improved work, anti-frost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

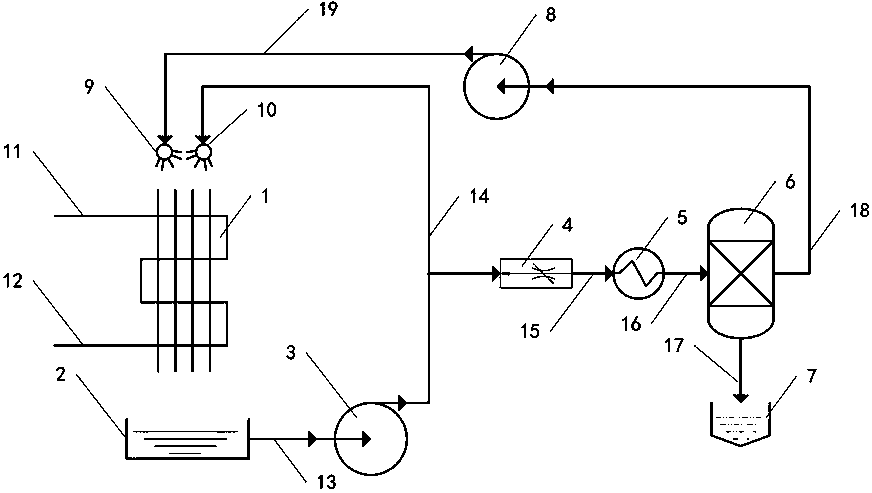

[0024] Such as figure 1 As shown, the embodiment of the present invention is a method for keeping the evaporator frost-free, spraying ethylene glycol with a lower freezing point temperature on the surface of the evaporating heat exchanger 1, and the ethylene glycol falls from the surface of the evaporating heat exchanger 1 into the collector In the liquid device 2, the main circulation pump 3 flows through the main circulation pipeline 14 and finally sprays out through the main nozzle 10. During the circulation spraying process, part of the ethylene glycol with a lower concentration enters the enrichment system for enrichment treatment and then passes through the secondary circulation. The pump 8 flows through the auxiliary circuit 19 and finally sprays through the auxiliary spray head 9 .

[0025] In the further optimized technical solution of the present invention, part of the ethylene glycol with a relatively low concentration is enriched by an enrichment device during the ...

Embodiment 2

[0033] Similar to Example 1, but what fails with Example 1 is that the antifreeze solution uses antifreeze salt solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com