Leaf spring assembly fatigue test bench

A leaf spring and fatigue test technology, which is applied in the testing of vehicle suspension/shock absorbing mechanisms, etc., can solve problems such as unfavorable electronic management of product information, difficulty in obtaining test data, and long time-consuming, so as to achieve accurate and reliable test results and simple structure , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

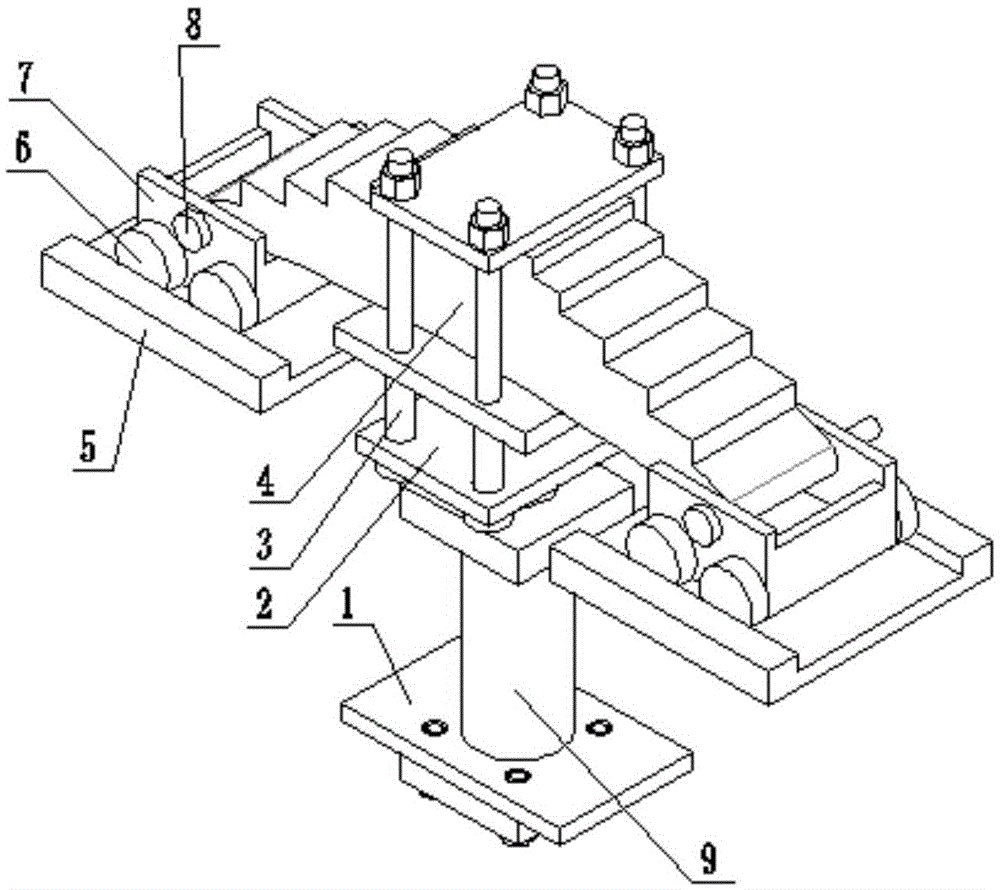

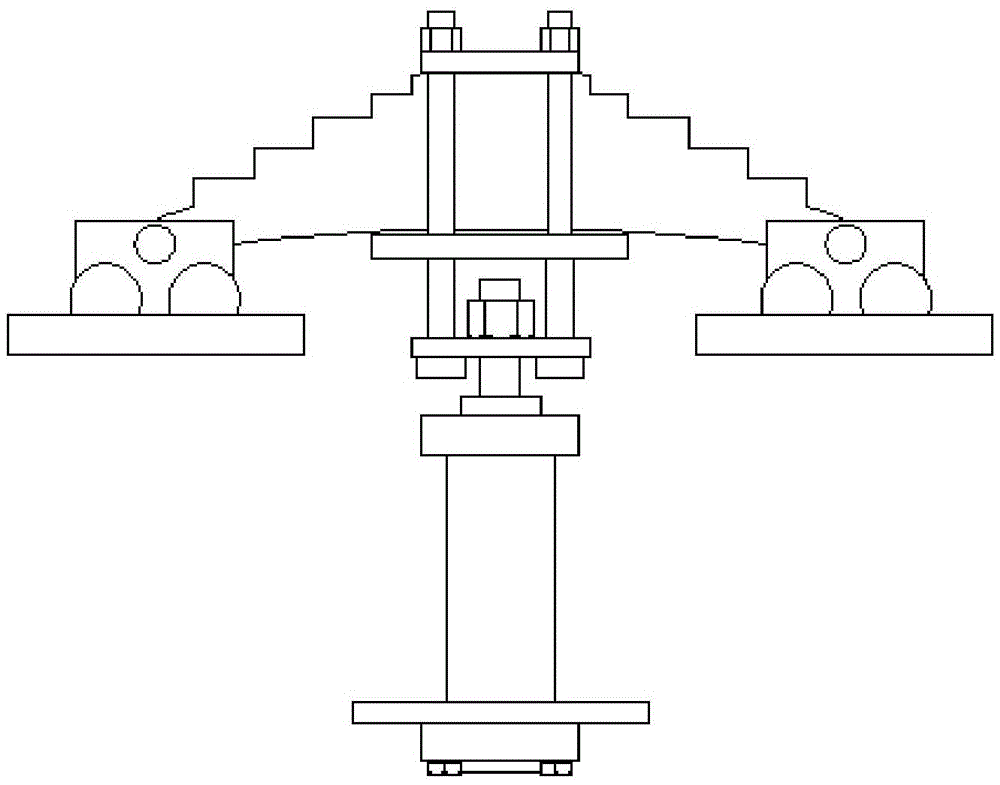

[0010] A leaf spring assembly fatigue impact test bench, see attached Figure 1-2 , mainly including base 1, movable plate 2, guide post 3, leaf spring assembly under test 4, guide rail 5, small wheel 6, trolley 7, mandrel 8, cylinder or oil cylinder 9. Wherein, the air cylinder or oil cylinder 9 is fixedly installed on the base 1, and its piston rod is arranged on the movable plate 2, and is fixedly connected with the movable plate; Driven by the rod, it slides along the four guide columns 3; the leaf spring assembly 4 to be tested is installed on the trolley 7 through the mandrel 8, and the trolley 7 has a small wheel 6, and the small wheel 6 is arranged in the guide rail 5 , and can slide along the guide rail 5, the guide rail 5 is a concave-convex rectangular chute, and the protrusions at both ends are higher than the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com