Non-excavation detection method and device of buried pipeline body defects

A detection method and buried pipeline technology, applied in the direction of material magnetic variables, etc., can solve the problems of large engineering volume, long time-consuming, high detection cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0037] Preferred embodiment:

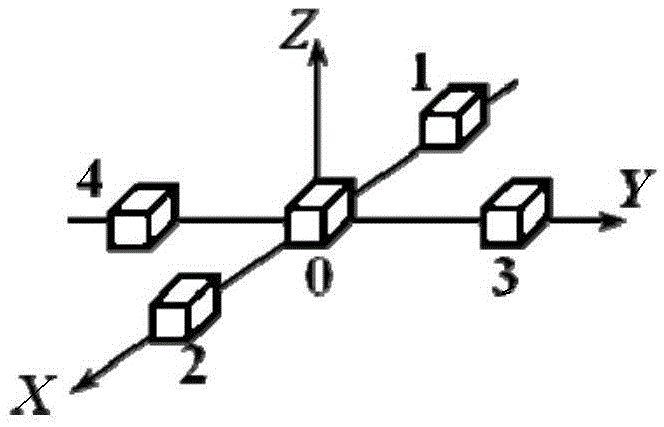

[0038] The preferred embodiment discloses a method for non-excavation detection of pipe body defects in buried pipelines and a device for realizing the method. The non-excavation detection device for pipe body defects of buried pipelines at least includes a casing and five detection elements arranged in the casing for detecting magnetic field vector values, wherein the detection elements are preferably three-axis magnetic sensors.

[0039] In this embodiment, the detection device is actually a typical detection instrument for magnetic gradient tensor, such as image 3 As shown, it specifically includes the No. 0 magnetic sensor located in the center, the No. 1 magnetic sensor and the No. 2 magnetic sensor which are located on both sides of the No. And the No. 3 magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com