Diffraction time-of-flight ultrasonic testing method for surface defects of thick-walled pipe girth welds

A diffraction time-of-flight and ultrasonic detection technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. and other problems, to achieve the effect of improving the signal-to-noise ratio of defects, improving the detection sensitivity, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] See attached Figure 7 , a method for diffraction time-of-flight ultrasonic testing of surface defects in girth welds of thick-walled pipes, the steps of the ultrasonic testing method are as follows:

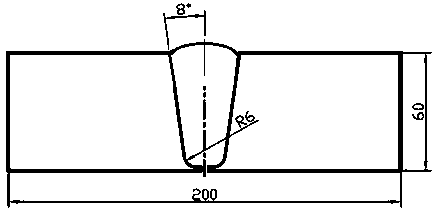

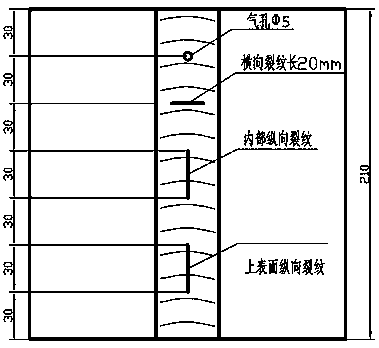

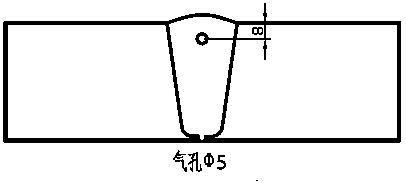

[0030] (1) Make a piece of material as a comparison test block of Q235-A;

[0031] The length, width, and height of the comparison test block in this example are 210mm×200mm×60mm. There is a weld seam in the center of the test block. There are four simulated defects in the weld, which are Φ5mm pores, 20mm long transverse cracks, internal longitudinal cracks and upper surface longitudinal cracks, and these defects are evenly distributed in the length direction of the test block.

[0032] (2) Place two shear wave oblique probes (transmitting probe 2 and receiving probe 3) symmetrically on the outer surfaces of the base me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com