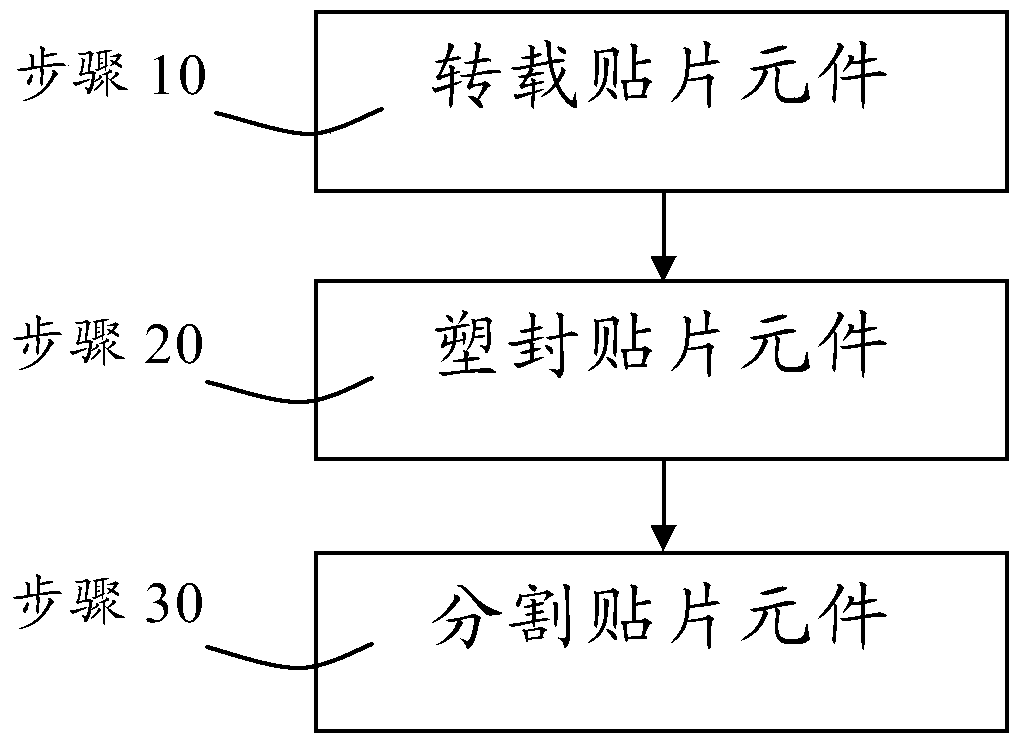

SMD component processing method

A technology for patch components and processing methods, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problems of easy short-circuiting, small electrode spacing, and contamination of the sides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

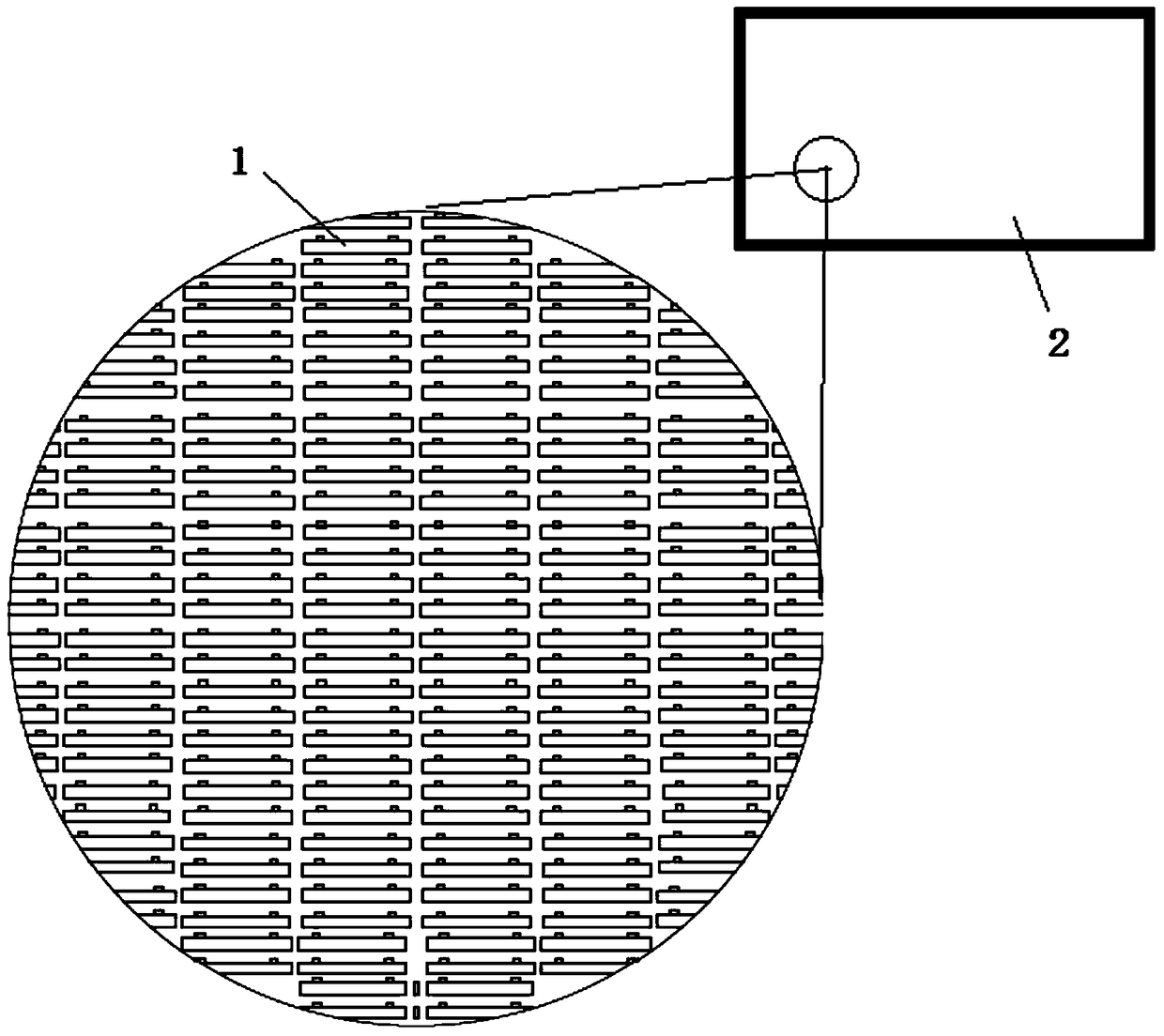

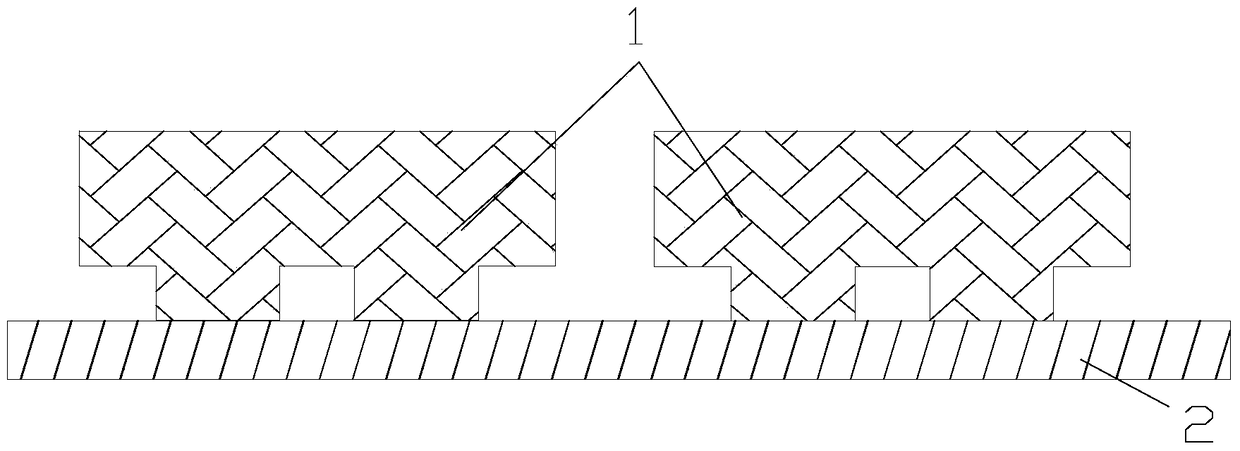

[0022] There are protruding electrodes 11 on the patch component, and when the patch component is transferred to the carrier 2 , the electrode 11 faces the carrying surface of the carrier 2 . Such as Figure 3A and 3B shown. That is, with the surface where the electrode 11 is located as the front, the surface of the patch component is placed on the carrier 2 facing the carrying surface, and the protruding electrodes 11 are supported on the carrying surface.

[0023] When placed in this way, a plastic sealing method may be: inject the plastic sealant 3 from above the patch component in a direction perpendicular to the bearing surface, and plastic seal the patch component. This can prevent the plastic sealant 3 from completely sealing the electrodes 11 , and there is no need to subsequently remove the plastic sealant 3 to expose the electrodes 11 .

[0024] Another way of molding is: injecting the molding compound 3 from the gap between the patch component and the bearing sur...

Embodiment 2

[0028] The patch component has a protruding electrode 11 , and when the patch component is transferred to the carrier 2 , the electrode 11 faces away from the carrying surface of the carrier 2 . Such as Figure 6 shown. That is to say, the surface where the electrode 11 is located is defined as the front side, and the opposite side is defined as the back side, and the back side of the chip component faces the carrying surface and is placed on the carrier.

[0029] In this way of placement, the molding compound 3 is injected from around the electrodes 11 during injection molding to seal the patch components. formed as Figure 7 structure shown. Injecting from all around can avoid completely encapsulating the electrode 11 into the injection molding glue.

[0030] The above two embodiments are optional two ways for processing and preparing patch components. The patch components processed in the above-mentioned manner of the present invention can avoid short circuits between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com