Novel NCA material and preparation method thereof

A new type of material-packed technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of coating damage, high pH value, easy water absorption, etc., and achieve the effect of reducing pH value and improving cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of novel NCA material provided by the present invention is made through the following steps successively: 1) 20g ammonium hexafluorophosphate is dissolved in 500g deionized water, stirs to dissolve completely, adds 1.6kg NCA (nickel cobalt aluminum Lithium acid) material, fully mix and stir to make it mix evenly;

[0026] 2) Dry in an oven, sieve, add to furnace and sinter at 400°C for 4 hours.

Embodiment 2

[0028] A kind of novel NCA material that the present invention provides, makes through following steps successively: 1) with 20g ammonium hexafluorophosphate, dissolve in 600g deionized water, stir to cause completely dissolving, add the NCA (nickel-cobalt-aluminum of 2.4kg wherein Lithium acid) material, fully mix and stir to make it mix evenly;

[0029] Dry it in an oven, sieve it, and put it into a furnace for sintering at 500°C for 2 hours.

Embodiment 3

[0031] A kind of novel NCA material provided by the present invention is made through the following steps successively: 1) 20g ammonium hexafluorophosphate is dissolved in 400g deionized water, stirs to dissolve completely, adds 1.6kg NCA (nickel cobalt aluminum Lithium acid) material, fully mix and stir to make it mix evenly;

[0032] 2) Dry in an oven, sieve, add to furnace and sinter at 500°C for 2 hours.

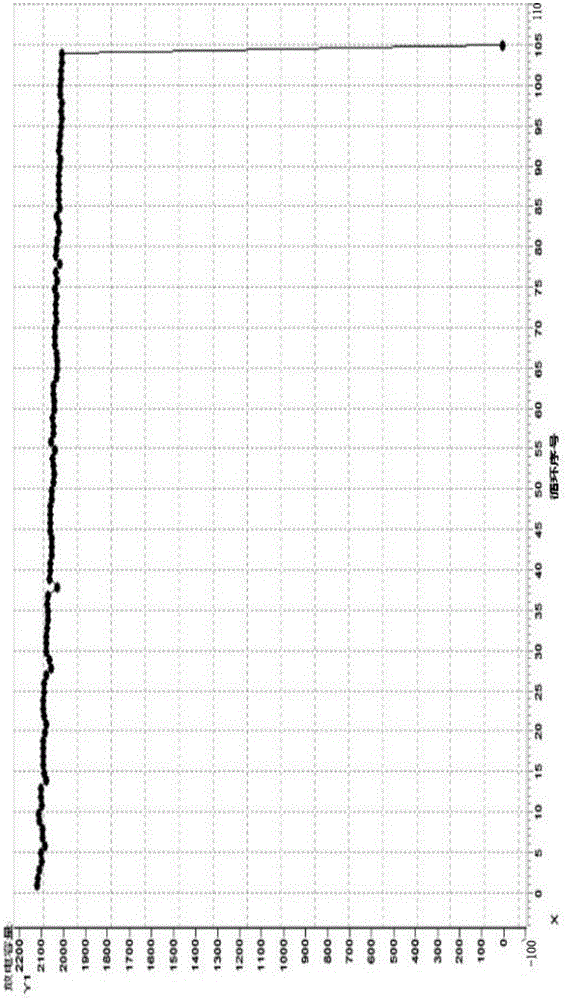

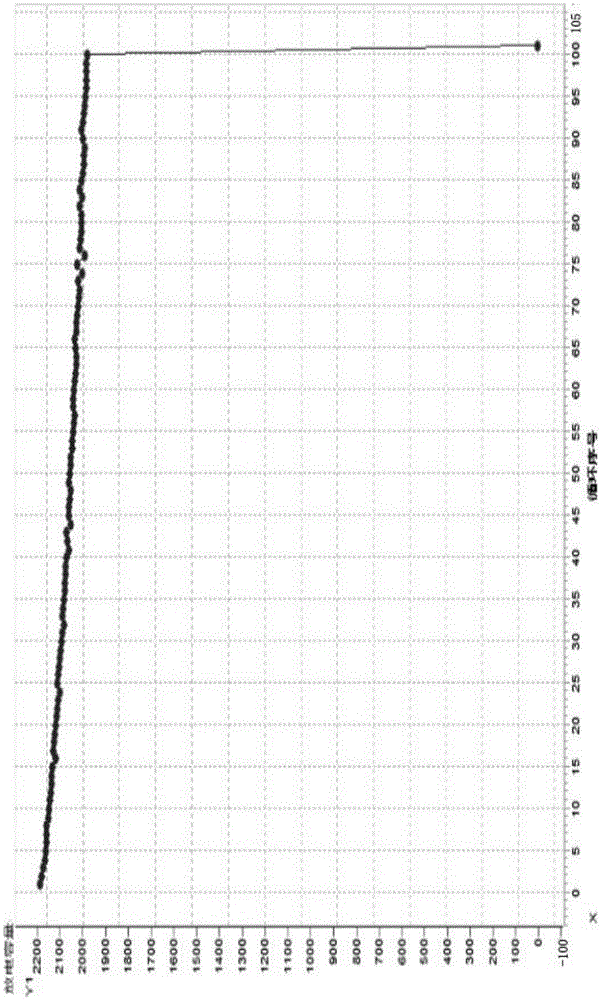

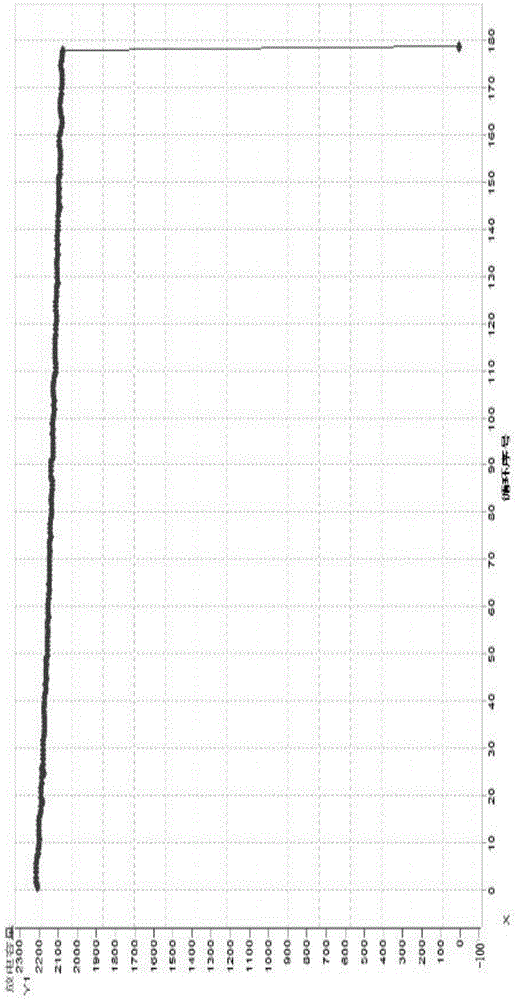

[0033] In order to better illustrate the advantages of the present invention, the capacity and cycle data of coated NCA materials after conventional water washing on the market are given below, see Figure 1 to Figure 3 , Table 1 to Table 3, the capacity and cycle data of NCA materials washed with water after coating, and the capacity and cycle data of NCA materials coated with ammonium hexafluorophosphate.

[0034] Table 1 The capacity and cycle data of coating after water washing

[0035]

[0036]

[0037] pass figure 1 As can be seen from Table 1, the coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com