High-strength, high-young's modulus steel plate, and manufacturing method thereof

A technology of Young's modulus and manufacturing method, which is applied in the field of high-strength and high Young's-modulus steel plate and its manufacturing field, can solve the problems such as the decrease of rigidity of the vehicle body, and achieve the effect of improving the fuel consumption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0212] Next, examples of the first embodiment will be described. It should be noted that the present invention is not limited to this embodiment.

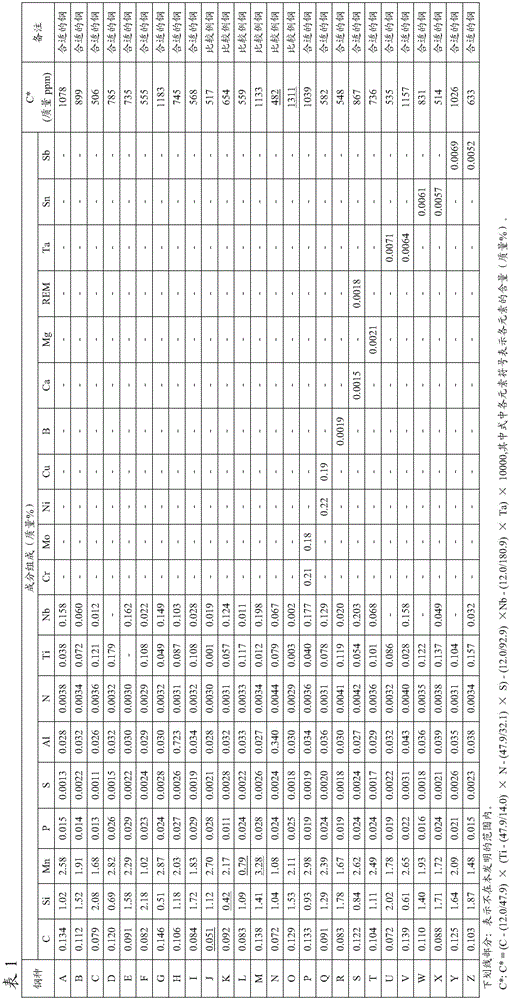

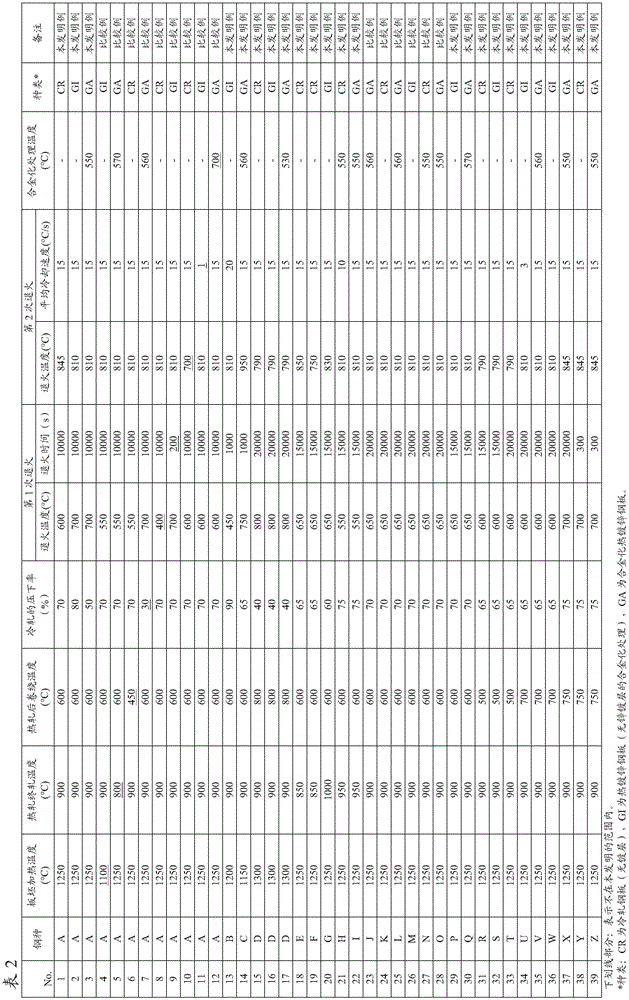

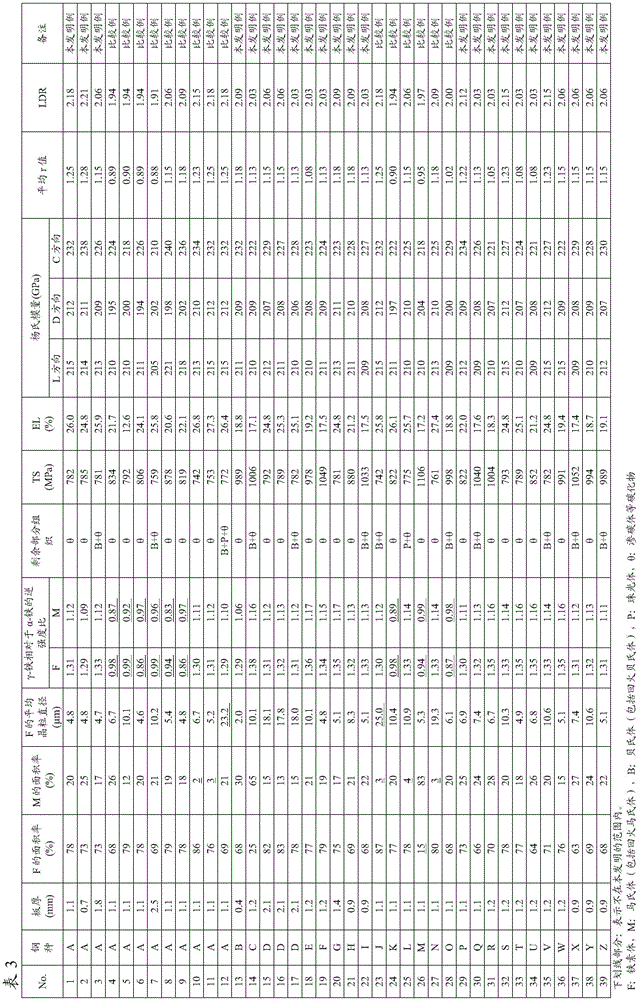

[0213] Steel having the composition shown in Table 1, with the balance being Fe and unavoidable impurities was melted in a converter and cast into slabs by continuous casting. The obtained slabs were hot-rolled under the conditions shown in Table 2, and then the obtained hot-rolled sheets were pickled. Next, cold rolling was carried out under the conditions shown in Table 2, and thereafter, heating (first annealing) and reheating (second annealing) shown in Table 2 were performed to produce cold-rolled steel sheets (CR: cold-rolled steel sheets (uncoated)). A part of the cold-rolled steel sheet is reheated (secondary annealing), and then hot-dip galvanized (GI: hot-dip galvanized steel sheet). In addition, a part of the cold-rolled steel sheet is reheated (secondary annealing), then hot-dip galvanized, and then further alloyed (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com