Automatic receiving control device for elemene industrial production

An automatic receiving and control device technology, applied in distillation adjustment/control, organic chemistry, distillation purification/separation, etc., can solve the problems of low yield, low elemene extraction efficiency, and inability to realize automatic control, etc. Yield and purity, labor saving, and the effect of improving first-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

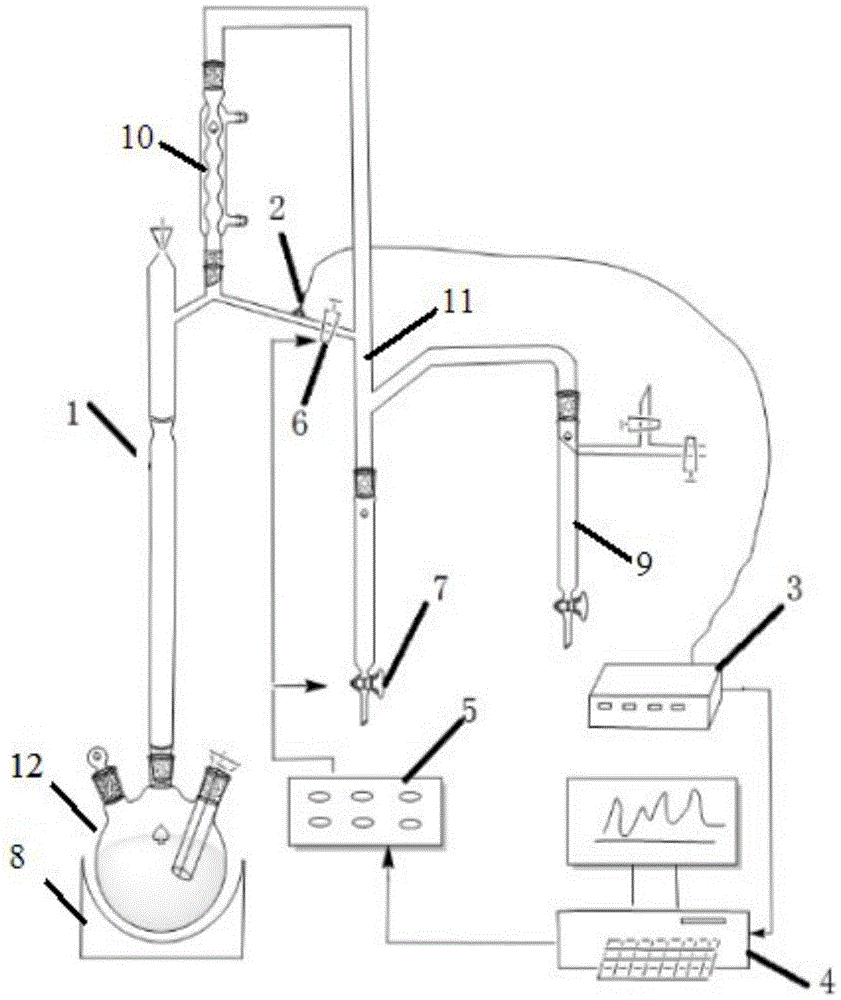

[0018] Automatic receiving control device for industrial production of elemene, including fractionation device 1, near-infrared probe 2, near-infrared spectrometer 3, online detection and analysis system 4, control center 5, automatic control valve A6, automatic control valve B7, heating device 8, buffer Pipe 9, condensing device 10, receiving device 11, raw material kettle 12.

[0019] The heating device 8 is located at the bottom of the raw material kettle 12 , and the raw material kettle 12 is connected with the bottom of the fractionation device 1 . Described fractionation device 1 is connected with condensing device 10 and receiving device 11 respectively, and fractionating device 1 is high 1.2 meters, is equipped with the packing that stainless steel net rolls inside, column number 45, vacuum degree 3mmHg, is provided with near-infrared filter on receiving device 11. The probe 2, the automatic control valve A6 and the buffer pipe 9, the bottom of the receiving device 11 ...

Embodiment 2

[0021] Automatic receiving control device for industrial production of elemene, including heating device 8, raw material kettle 12, fractionation device 1, condensation device 10, near-infrared probe 2, receiving device 11, near-infrared spectrometer 3, online detection and analysis system 4, control center 5 and automatic control valves;

[0022] The heating device 8 is connected with the raw material kettle 12, and the raw material kettle 12 is connected with the bottom of the fractionation unit 1, and the fractionation unit 1 is respectively connected with the condensing unit 10 and the receiving unit 11 through the fractionation outlet. The height of the fractionation unit 1 is 1.2 meters. Packing made of stainless steel mesh, the number of trays is 40, and the vacuum degree is 1mmHg. The receiving device 11 is provided with a near-infrared probe 2 and an automatic control valve A6, the bottom of the receiving device 11 is provided with an automatic control valve B7, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com