Preparation method for red mud-based iron-series catalyst and application of red mud-based iron-series catalyst in hydrogen production through cracking of methane

A catalyst and red mud technology, which is applied in the field of preparation of red mud-based iron-based catalysts, can solve the problems of low catalytic activity and stability, low content of active metal iron, and underdeveloped pore structure, etc., to achieve high added value Utilization, developed pore structure, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of red mud-based iron-based catalyst, comprising the following steps in parts by weight:

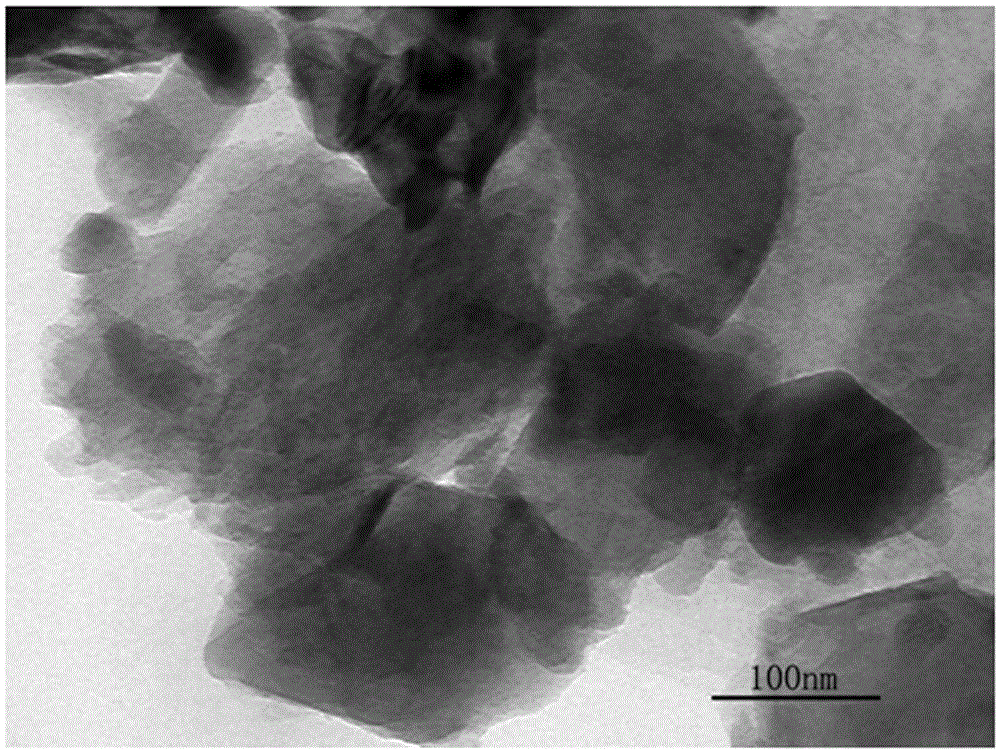

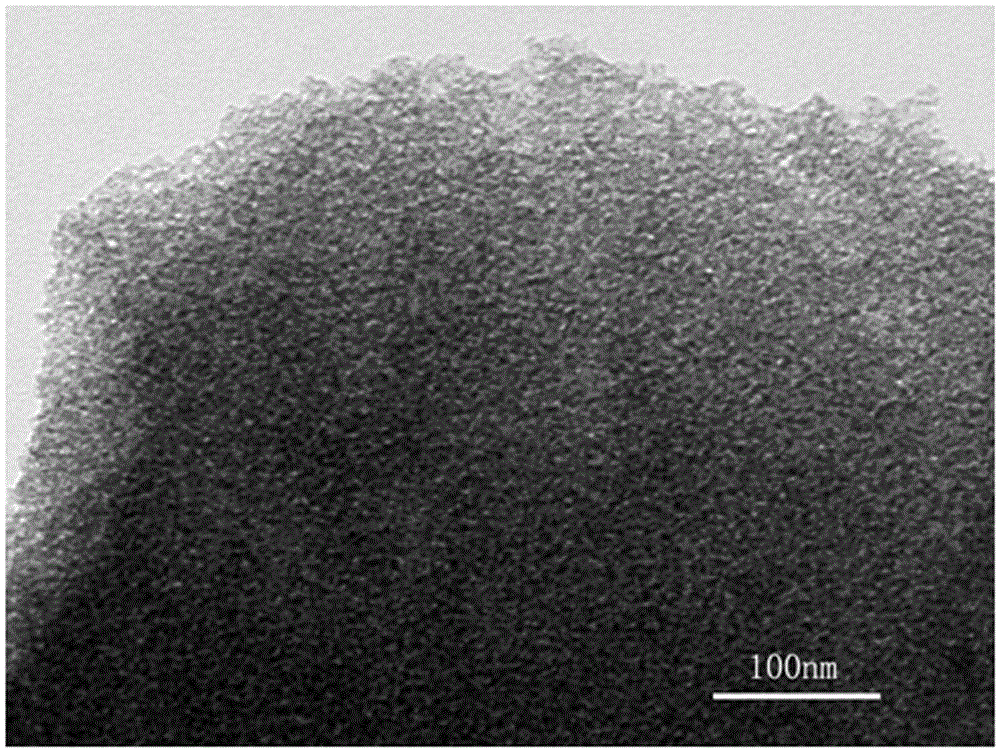

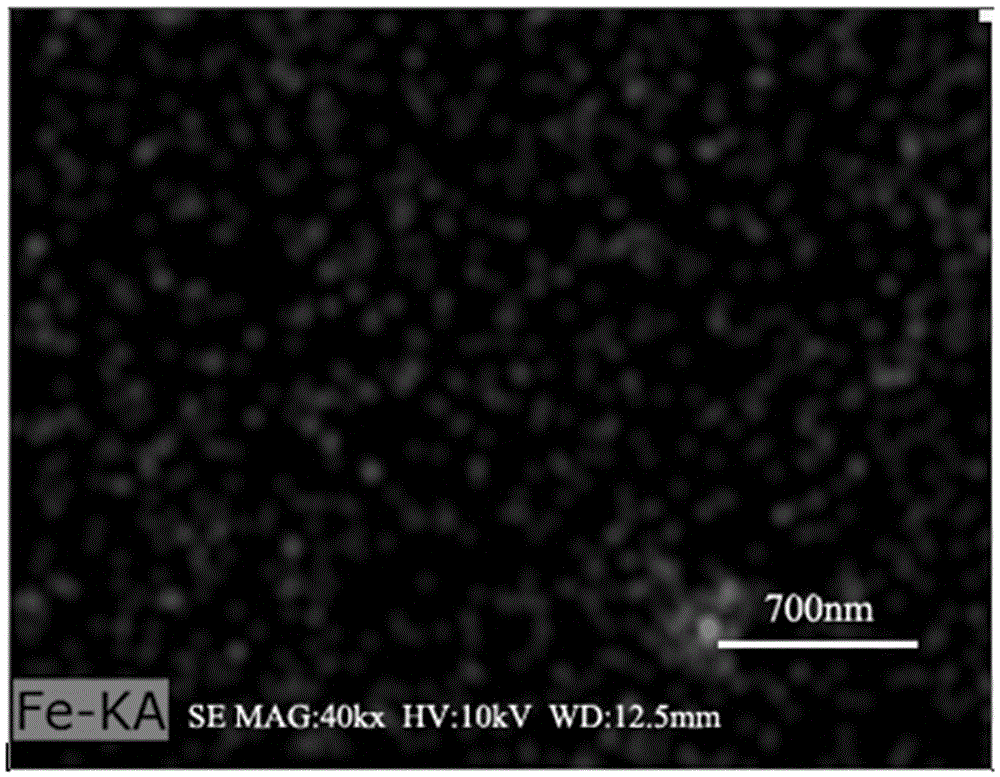

[0030] First dry the red mud at 100-120°C for 1-4 hours, crush, grind and sieve until the particle size is less than 75μm, take 10g of the dried red mud sample and put it into a 1000ml large beaker, pour 100ml of deionized water into the beaker, and stir After uniformity, put it into an ultrasonic cleaner for 3 minutes; then pour 500ml of pre-prepared 1mol / L dilute hydrochloric acid into the beaker, stir well, put it in a water bath with magnetic stirring, and place it in a constant temperature water bath at 60°C for 2 hours. Stirring rate is 300r / min; By the mass percent of Fe 10% (namely Fe(NO 3 ) 3 9H 2 The mass of elemental Fe in O accounts for the percentage of 10g raw material red mud mass after drying) accurately weighs 7.21g of Fe (NO 3 ) 3 9H 2 Dissolve O in 50ml of absolute ethanol, pour it into a beaker and stir evenly, then use ammonia water t...

Embodiment 2

[0036] A preparation method of red mud-based iron-based catalyst, comprising the following steps in parts by weight:

[0037]First dry the red mud at 100-120°C for 1-4 hours, crush, grind and sieve until the particle size is less than 75μm, take 10g of the dried red mud sample and put it into a 1000ml large beaker, pour 100ml of deionized water into the beaker, and stir After uniformity, put it into an ultrasonic cleaner for 3 minutes; then pour 500ml of pre-prepared 1mol / L dilute hydrochloric acid into the beaker, stir well, put it in a water bath with magnetic stirring, and place it in a constant temperature water bath at 60°C for 2 hours. Stirring speed is 300r / min; By the mass percent of Fe 20% (namely Fe(NO 3 ) 3 9H 2 The mass of elemental Fe in O accounted for the percentage of dried 10g raw material red mud mass) accurately weighed 14.42g of Fe (NO 3 ) 3 9H 2 Dissolve O in 50ml of absolute ethanol, pour it into a beaker and stir evenly, then use ammonia water to pr...

Embodiment 3

[0043] A preparation method of red mud-based iron-based catalyst, comprising the following steps in parts by weight:

[0044] First dry the red mud at 100-120°C for 1-4 hours, crush, grind and sieve until the particle size is less than 75μm, take 10g of the dried red mud sample and put it into a 1000ml large beaker, pour 100ml of deionized water into the beaker, and stir After uniformity, put it into an ultrasonic cleaner for 3 minutes; then pour 500ml of pre-prepared 1mol / L dilute hydrochloric acid into the beaker, stir well, put it in a water bath with magnetic stirring, and place it in a constant temperature water bath at 60°C for 2 hours. Stirring speed is 300r / min; By the mass percent of Fe 30% (namely Fe(NO 3 ) 3 9H 2 The mass of elemental Fe in O accounts for the percentage of 10g raw material red mud mass after drying) accurately weighs 21.63g of Fe (NO 3 ) 3 9H 2 Dissolve O in 50ml of absolute ethanol, pour it into a beaker and stir evenly, then use ammonia water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com