Rod type screen bottom of pulverized coal vibrating screen

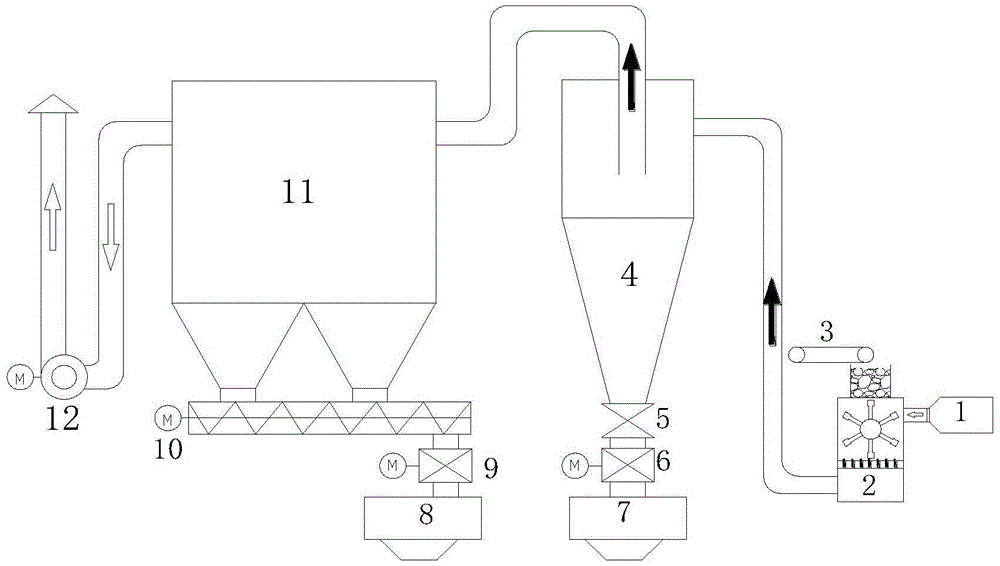

A rod-type, sieve-bottom technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of rod fatigue fracture, blast furnace spray gun blockage, and influence on the quality of coal powder, so that it is not easy to vibrate and crack, and the quality is ensured , Easy to clean the bottom of the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

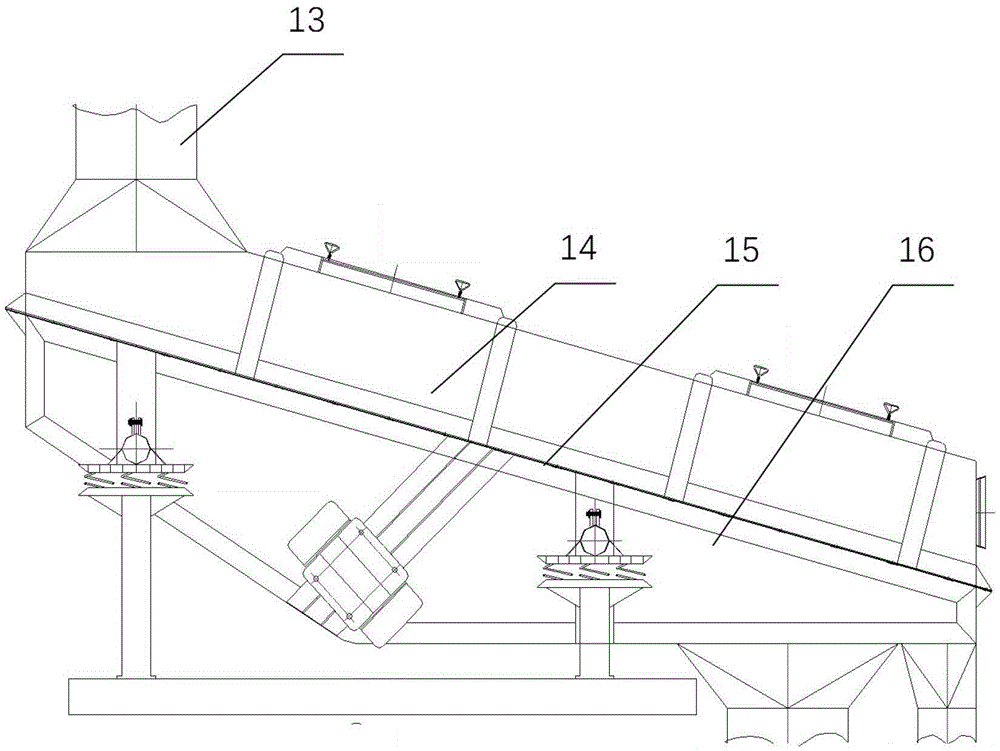

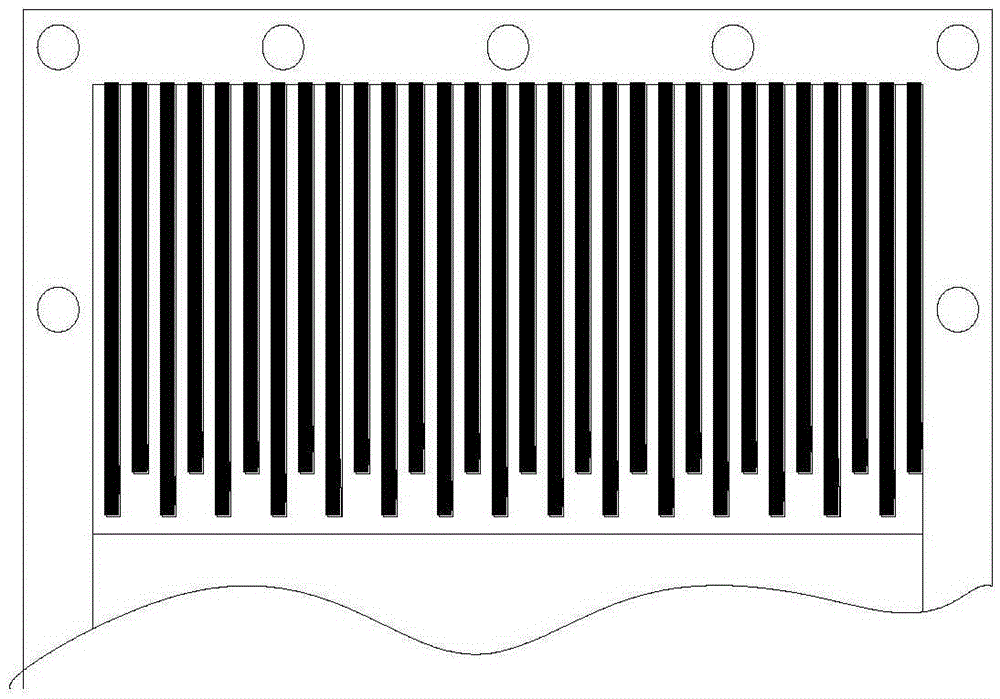

[0024] Such as Figure 4 with Figure 5 As shown, a sieve bottom of a rod-type pulverized coal vibrating screen includes a three-layer screen group, and any one of the three-layer screen groups includes a rod-type screen 17 and The U-shaped square-hole screen 18 is provided with a sealing strip 19 between the rod-shaped screen 17 and the U-shaped square-hole screen 18 and fixed together by a fixing member 20.

[0025] The screen groups shown are the upper, middle, and lower layers.

[0026] According to the installation size of the bar screen, three square-hole screens with a U-shaped structure are produced. A sealing strip is added between the two layers of screens, and flange bolts are used to connect and install the upper and lower sieve bodies in the pulverized coal vibrating screen. After the installation of the sieve bottom is completed, the production test of granular coal pulverization can be started. During this period, attention should be paid to parameters such as pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com