Notching machine for retaining rings

A cutting machine and buckle technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low work efficiency, high labor and time costs, time-consuming and other problems, and achieve a high degree of automation and production efficiency. The effect of saving manpower and time costs and avoiding the loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings to make the solution more clear.

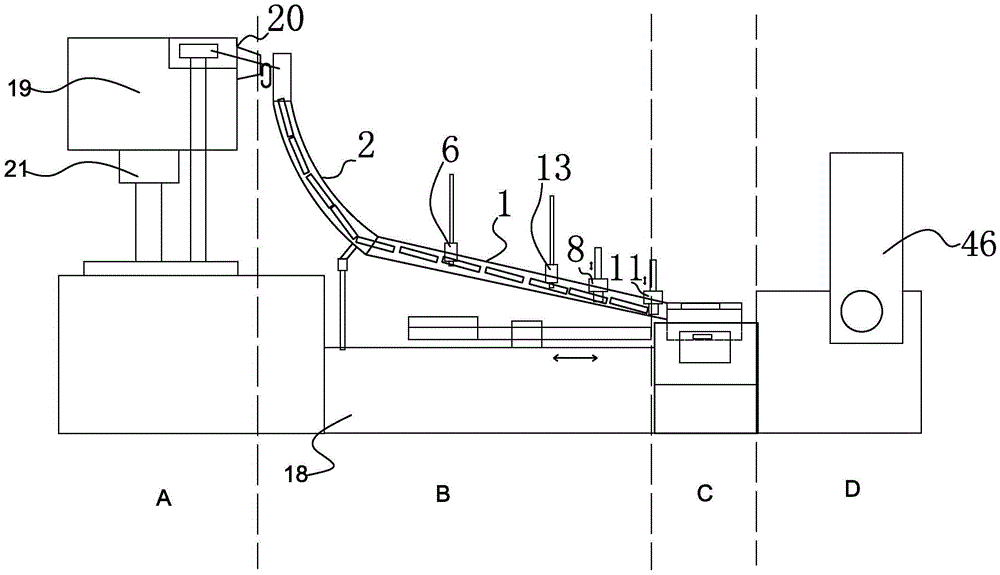

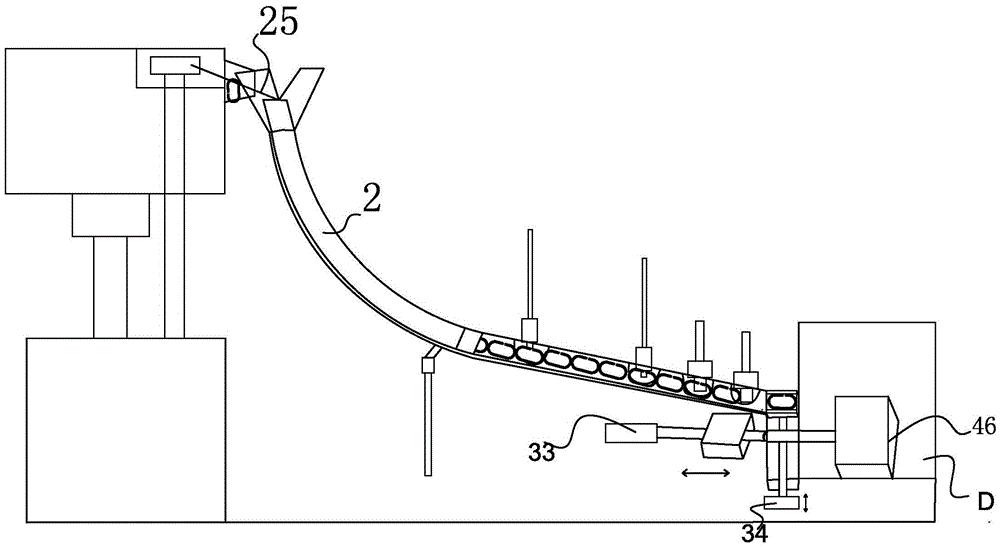

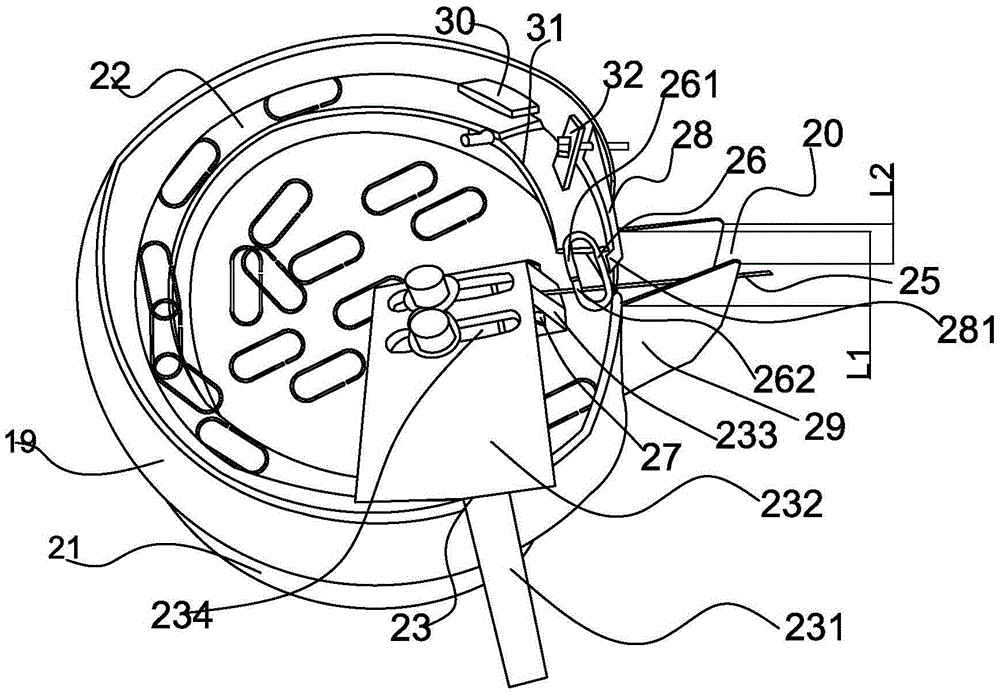

[0038] Such as figure 1 , figure 2 with Figure 4 As shown, the buckle slitting machine includes a feeding device A, a guide transmission device B, a feeding device C and a punch device D arranged on the frame 18 in sequence, and the feeding device includes a feeding bin 19, and the upper part of the feeding bin A discharge port 20 is provided, and the guide transmission device includes an inclined transmission channel 1, the highest end 1a of the transmission channel is connected to an arc-shaped guide plate 2, and a guide channel 3 is arranged in the guide plate, and the lowest end 2a of the guide channel is connected to the bottom of the transmission channel. The highest end 1a is connected. The middle part of the transmission channel 1 has a groove 4 for raw material transmission, and the upper part of the groove is covered with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com