Purification process for phosphorus pentoxide

A technology of phosphorus pentoxide and process is applied in the field of purification of phosphorus pentoxide, which can solve the problems of long purification process, incomplete filtration and impurity removal, and many yellow phosphorus raw materials, so as to reduce energy consumption and improve energy utilization rate. , the effect of preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The purification process of phosphorus pentoxide comprises the following steps:

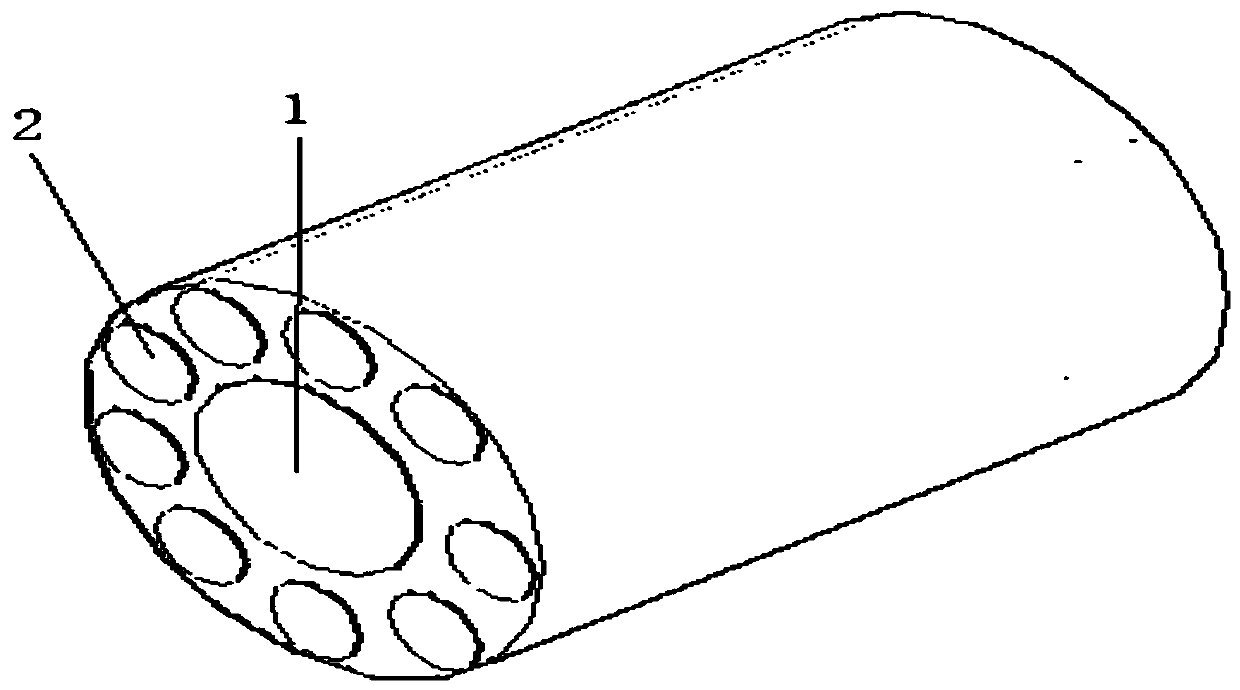

[0030] a) Raw material processing: select industrial yellow phosphorus, isolate air heating to melt it into liquid yellow phosphorus, and pass such as figure 1 The shown interior is surrounded by an inorganic ceramic membrane pipeline 1 with a plurality of insulation tubes 2 to separate and remove insoluble impurities such as silicon;

[0031] b) primary combustion: the air is processed through 5A molecular sieves, then dried and filtered, and the air humidity is controlled to be 8ppm; the separated liquid yellow phosphorus described in step a) is placed in the reactor, and the liquid yellow phosphorus is passed into The treated air is controlled at an air flow rate of 450ml / min, and burned on the surface of liquid yellow phosphorus to generate crude phosphorus pentoxide gas;

[0032] c) primary cooling: pass the crude phosphorus pentoxide gas described in step b) through a 30°C liquid co...

Embodiment 2

[0037] The purification process of phosphorus pentoxide comprises the following steps:

[0038] a) Raw material treatment: select industrial yellow phosphorus, heat it in isolation from the air to melt it into liquid yellow phosphorus, and separate and remove insoluble impurities such as silicon through the inorganic ceramic membrane channel 1 without multiple insulation tubes 2;

[0039] b) primary combustion: the air is processed through 5A molecular sieves, then dried and filtered, and the air humidity is controlled to be 8ppm; the separated liquid yellow phosphorus described in step a) is placed in the reactor, and the liquid yellow phosphorus is passed into The treated air is controlled at an air flow rate of 450ml / min, and burned on the surface of liquid yellow phosphorus to generate crude phosphorus pentoxide gas;

[0040] c) primary cooling: pass the crude phosphorus pentoxide gas described in step b) through a 30°C liquid cooler to cool the phosphorus pentoxide into a...

Embodiment 3

[0045] The purification process of phosphorus pentoxide comprises the following steps:

[0046] a) Raw material processing: select industrial yellow phosphorus, isolate air heating to melt it into liquid yellow phosphorus, and pass such as figure 1 The shown interior is surrounded by an inorganic ceramic membrane channel 1 with a plurality of insulation tubes 2 to separate and remove insoluble impurities such as silicon;

[0047] b) primary combustion: the air is processed through 5A molecular sieves, then dried and filtered, and the air humidity is controlled to be 8ppm; the separated liquid yellow phosphorus described in step a) is placed in the reactor, and the liquid yellow phosphorus is passed into The treated air is controlled at an air flow rate of 470ml / min, and is burned on the surface of liquid yellow phosphorus to generate crude phosphorus pentoxide gas;

[0048] c) primary cooling: pass the crude phosphorus pentoxide gas described in step b) through a 30°C liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com