Cooling device for motor of slicing machine

A technology of cooling device and slicer, applied in electromechanical devices, cooling/ventilation devices, metal processing, etc., can solve problems such as poor cooling effect and affect motor performance, and achieve the effect of reducing investment, reducing operating costs, and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

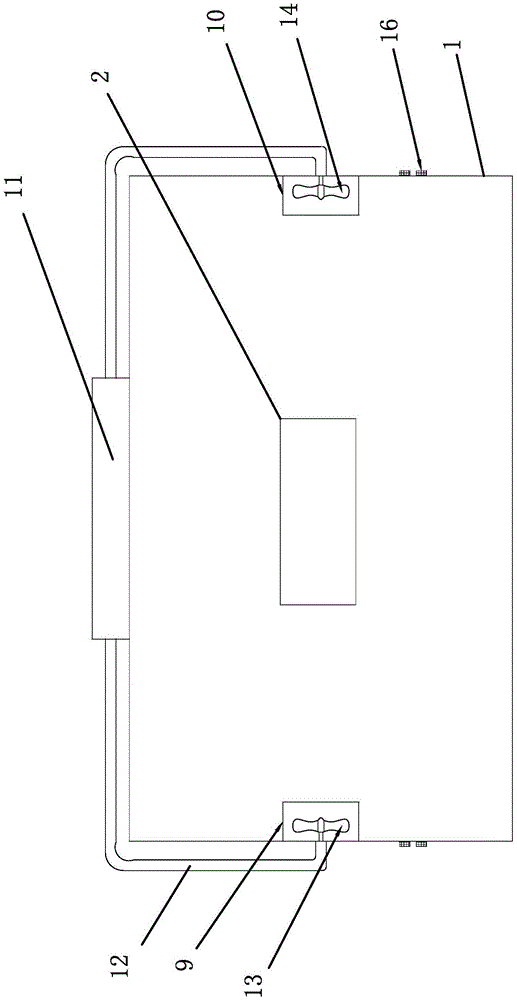

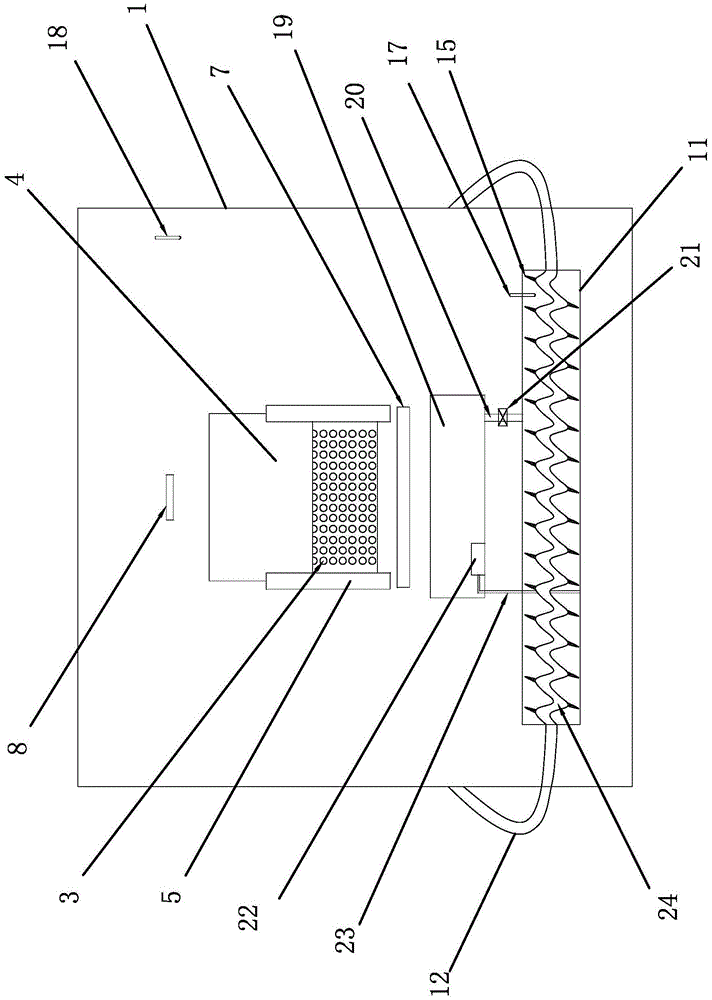

[0032] Such as figure 1 , figure 2 , image 3 As shown, the cooling device of the motor 2 of the slicer, the slicer includes a chassis 1 and a motor 2 located in the chassis 1, the chassis 1 is in the shape of a cuboid, the front of the chassis 1 has an openable door, and the cooling device includes the back of the chassis 1 There are some air vents 3 that communicate with the outside air, and a rectangular baffle plate 4 that can block the air vents 3 is provided on the outside of the back of the cabinet 1. Several air vents 3 on the back of the middle cabinet 1 are arranged equidistantly and form a rectangle.

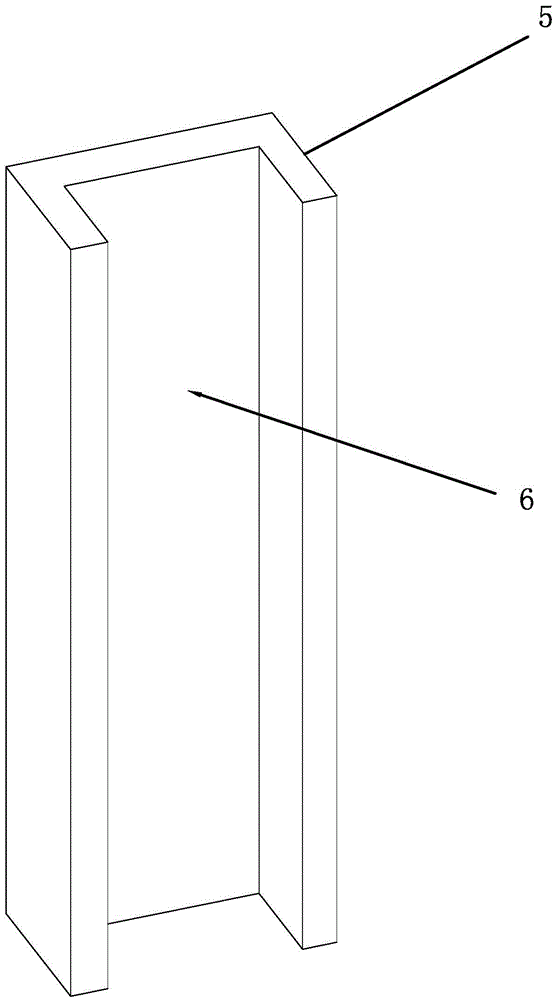

[0033] Both sides of baffle plate 4 are provided with vertically arranged guide slide bars 5, and guide sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com