Mechanism for forming side lugs on ampoule penicillin bottle packaging cartons

An ampoule vial and carton technology, applied in packaging and other directions, can solve the problems of slow production speed, affect product production efficiency and production cost, and difficult to maintain, and achieve the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

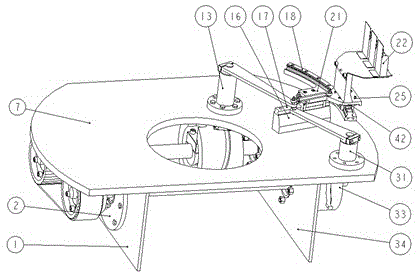

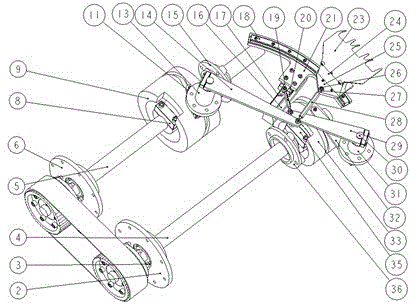

[0018] Such as Figure 1-6 As shown, the present invention includes a frame, a main drive, a front and rear motion cam linkage, and a left and right motion cam linkage; the frame includes a front brace 34, a rear brace 1 and a platen 7, and the front brace 34 Welded with the back support plate 1 under the platen 7;

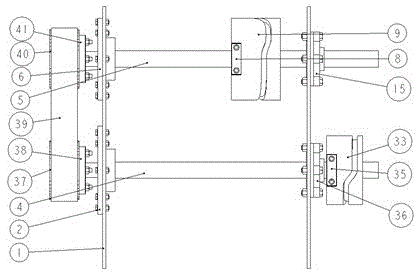

[0019] Described main transmission comprises input shaft 4, power transmission shaft 5, input synchronous pulley 37, input mounting plate 38, transmission synchronous pulley 40, transmission mounting plate 41, synchronous belt 39, input front bearing seat 36, input rear bearing seat 2, transmission front bearing seat 15, transmission rear bearing seat 6; described input shaft 4 is installed on the frame with bolts through input front bearing seat 36 and input rear bearing seat 2, and transmission shaft 5 passes transmission front bearing seat 15 and Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com