A stainless steel pickling wastewater treatment system and treatment method

A technology of pickling wastewater and treatment system, applied in the field of industrial wastewater treatment, can solve the problems of increasing treatment cost, occupying land resources, unable to completely eliminate the harm of high-valent chromium, and achieving the effect of eliminating concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

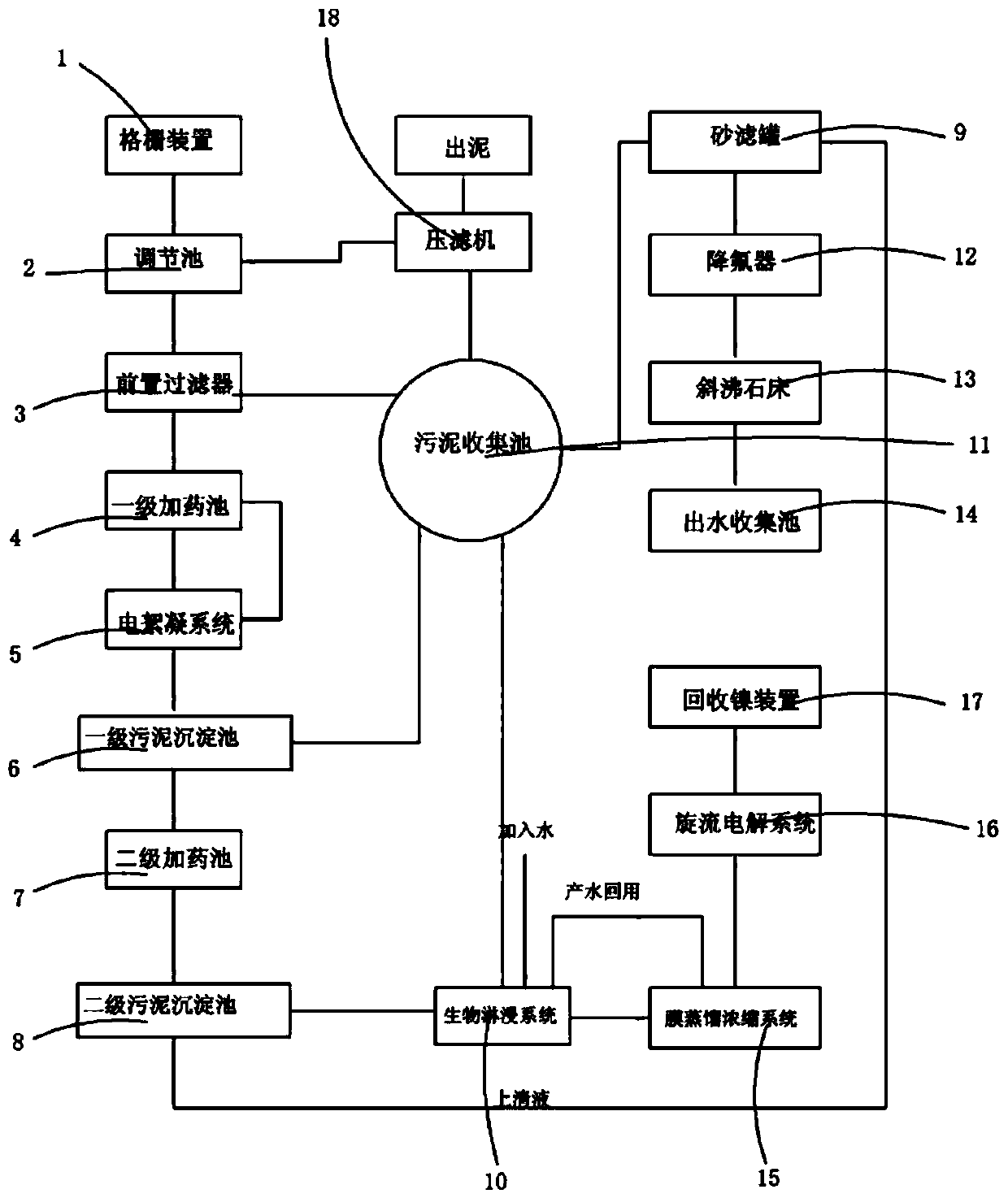

[0034] Examples, see attached figure 1, a stainless steel pickling wastewater treatment system, comprising a grille device 1, the grille device is connected to a regulating pool 2, the regulating pool is connected to a pre-filter 3, and the pre-filter is connected to a primary dosing pool 4, The outlet end of the first-level dosing pool is connected to the high-frequency pulse electrocoagulation system 5, and the outlet end of the high-frequency pulse electrocoagulation system is connected to the first-level dosing pool, so that the first-level dosing pool and the high-frequency pulse electrocoagulation The system forms a closed circuit; the high-frequency pulse electrocoagulation system is connected to the first-level sludge sedimentation tank 6, and the first-level sludge sedimentation tank enables the iron and chromium bottom sludge precipitated after the wastewater is stirred and reacted by the high-frequency pulse electrocoagulation system to be independently Concentrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com