Repairing method for flow guiding bars in combustor during hot blast heater repairing

A repair method and burner technology, which is applied to furnaces, blast furnaces, heating furnaces, etc., can solve the problems of new and old stubble butt joints and poor sealing, and achieve the problems of poor butt joint and seal, tight joint and seal, and improved reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

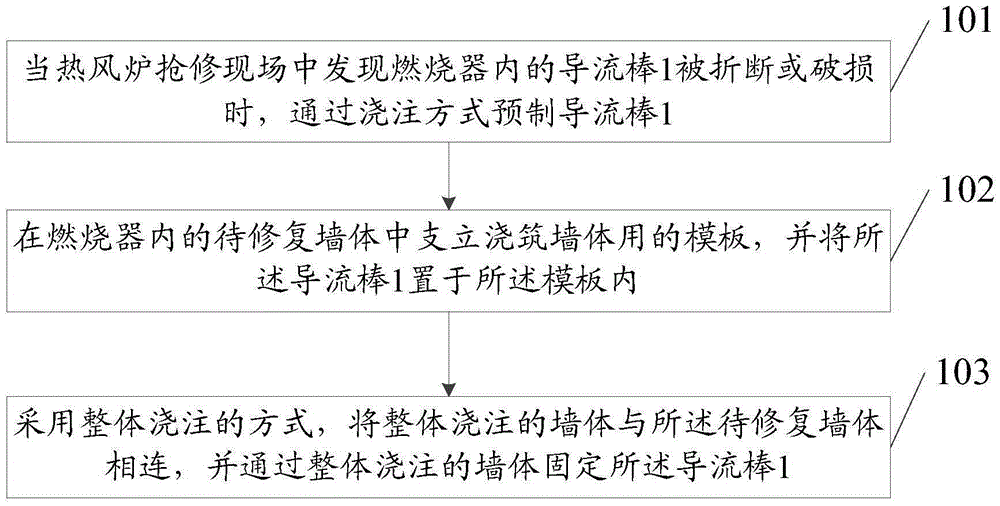

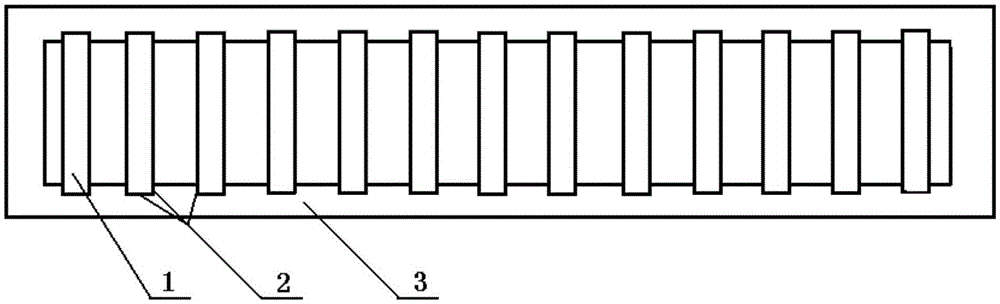

[0024] Please refer to figure 1 , the embodiment of the present application provides a method for repairing the guide rod 1 in the burner in the emergency repair of the hot blast stove, including:

[0025] Step 101: Prefabricate the guide rod 1 by pouring when it is found that the guide rod 1 in the burner is broken or damaged at the repair site of the hot blast stove;

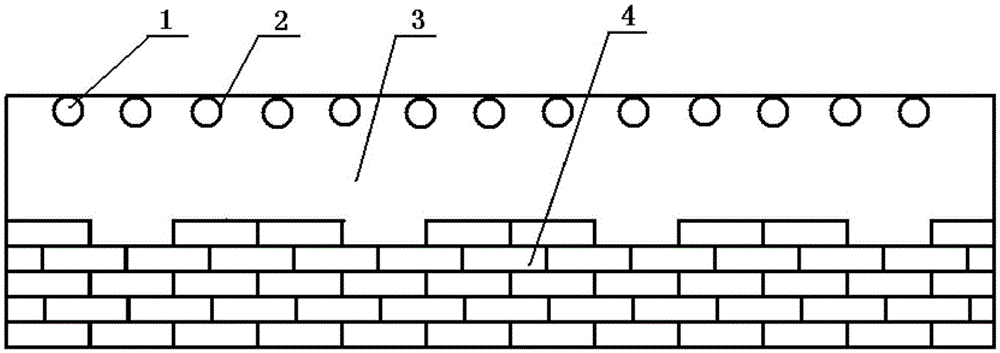

[0026] Step 102: Support the formwork for pouring the wall in the wall to be repaired in the burner, and place the guide rod 1 in the formwork;

[0027] Step 103: Connect the integrally casted wall with the wall to be repaired by integral casting, and fix the guide rod 1 through the integrally casted wall.

[0028] The hot blast stove is a thermal equipment that integrates combustion and heat transfer processes to provide hot air flow for process needs. Its structure includes a combustion chamber and a burner. The burners of blast furnace hot blast stoves are basically devices suitable for burning gaseous fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com